Integral catalyst for producing dimethyl ether by synthesis gas directly as well as its preparing method

A monolithic catalyst, dimethyl ether technology, applied in ether preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of large particles, easy sintering of active components, poor catalytic activity, etc., and achieve the effect of high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

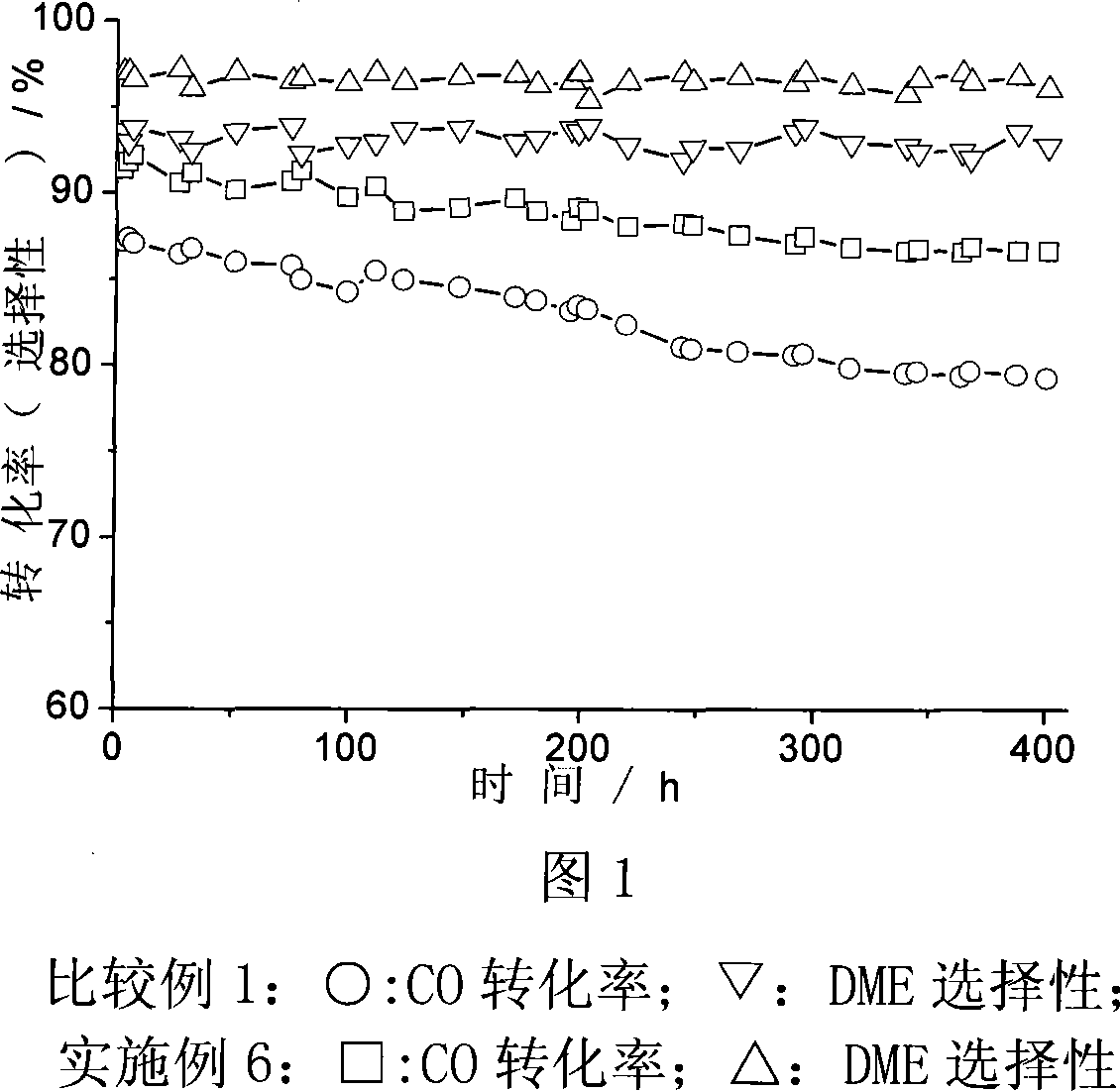

Examples

Embodiment 1

[0026] Embodiment 1 (method 1): (1) the commercially available 400cpsi monolithic honeycomb cordierite (the same cordierite used in the following examples) was cut into a cylindrical sample of φ7mm×20mm, washed and dried; 26wt% HNO 3 The cordierite was treated with solution for 2 hours, then washed with deionized water until the filtrate was neutral, dried at 120°C for 1 hour, calcined at 550°C for 4 hours, and cooled naturally to obtain the pretreated cordierite matrix.

[0027] (2) Weigh a certain amount of NaOH, NaAlO 2 Dissolve in deionized water, stir to dissolve, slowly add tetrapropylammonium bromide (TPRBr), stir evenly, add quantitative tetraethyl orthosilicate dropwise and stir evenly, the molar ratio of each component in the final solution is: Al 2 o 3 : 80SiO 2 :9.6Na 2 O: 4800H 2 O: 17.2TPABr. Then put the pretreated cordierite obtained in step (1) into the autoclave together with the synthesis solution, and crystallize at 190°C for 48 hours. After cooling, ...

Embodiment 2

[0030] Embodiment 2 (method 1): (1) monolithic cordierite pretreatment method, with the step (1) of embodiment 1. (2) In-situ growth of HZSM-5 molecular sieve on monolithic cordierite, the method is the same as step (2) in Example 1, except that the molar ratio of the raw material solution is Al 2 o 3 : 80SiO 2 : 20Na 2 O: 10000H 2 O: 21.5TPABr.

[0031] (3) 10.872 grams of Cu(NO 3 ) 2 ·3H 2 O, 8.8902 g Zn(NO 3 ) 2 ·6H 2 O and 2.813 g Al(NO 3 ) 3 9H 2 O was dissolved in 82.3 mL of deionized water. Mix the mixed nitrate solution with 1mol / LNa 2 CO 3 The aqueous solution was added dropwise to a beaker filled with 100 mL of deionized water for co-precipitation. The precipitation temperature is 80°C, and the pH is maintained at about 7.0. After co-precipitation, continue to stir and age at 70°C for 1.0h. Others are with embodiment 1 step (3).

[0032] (4) Add the granular catalyst obtained in step (3) to dilute HNO 3 Grinding with deionized water with a ball mi...

Embodiment 3

[0033] Embodiment 3 (method 2): with 10.872 grams of Cu (NO 3 ) 2 ·3H 2 O, 6.693 g Zn(NO 3 ) 2 ·6H 2 O, 1.125 g Al(NO 3 ) 3 9H 2 O and 1.45 g ZrOCl 2 ·8H 2 O was dissolved in 82.8 mL of deionized water. Mix the mixed nitrate solution with 1mol / LNa 2 CO 3 The aqueous solution was added dropwise to a beaker filled with 100 mL of deionized water for co-precipitation. The precipitation temperature is 75°C, and the pH is maintained at about 8.0. After co-precipitation, continue to stir and age at 75°C for 1.0h. The precipitate was filtered and washed to obtain precipitate 1. Add 2.016g of HZSM-5 into 100mL of deionized water, and oscillate ultrasonically for 20min to obtain suspension 2. The precipitate 1 was added to the suspension 2, stirred for 3 hours, filtered and washed, baked under an infrared lamp for 10 hours, and roasted at 350° C. for 4 hours to obtain a dimethyl ether synthesis catalyst. Others are the same as example 1 step (4), but repeat the cordierit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com