Solid catalyst for preparing diol by hydrating epoxy compound as well as preparation and application thereof

A solid catalyst and ligand technology, which can be used in the preparation of organic compounds, organic compounds/hydrides/coordination complex catalysts, preparation of hydroxyl compounds, etc., and can solve the problems of complicated preparation steps, high cost, poor stability of solid catalysts, etc. , to achieve the effect of good selectivity, easy separation and good tunability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

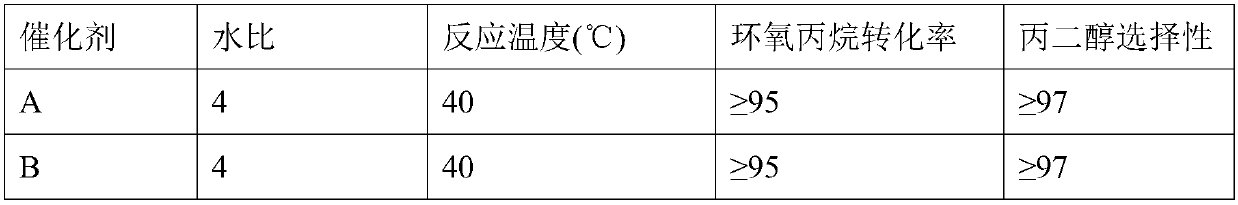

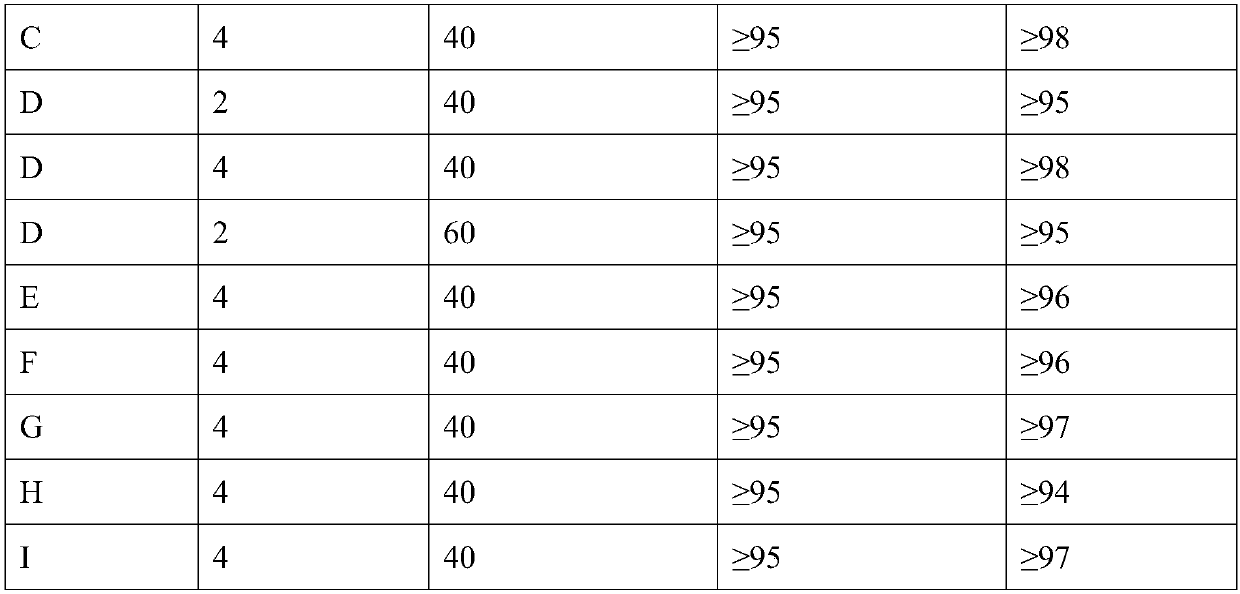

Embodiment 1

[0021] The preparation of the catalyst is as follows: Dissolve 3.3 g of cobalt nitrate in 30 ml of absolute ethanol, mix and stir for 30 min, add 20 ml of ethanol containing 9.85 g of 2-methylimidazole, mix and stir for 30 min, add dropwise 10 ml of ethanol solution containing 3.3 g of zinc nitrate, After mixing, stir for 30 minutes, add dropwise 1ml of formic acid solution, add 4mmol of salicylaldehyde, stir, add 3mmol of o-diphenylamine, reflux for 12h, cool, separate the solid, wash and dry to obtain catalyst A.

Embodiment 2

[0023] The preparation of the catalyst is as follows: Dissolve 3.3 g of cobalt nitrate in 30 ml of absolute ethanol, mix and stir for 30 min, add 20 ml of ethanol containing 9.85 g of 2-methylimidazole, mix and stir for 30 min, add dropwise 10 ml of ethanol solution containing 3.3 g of zinc nitrate, After mixing, stir for 30 minutes, add 1ml of formic acid solution dropwise, add 8mmol of salicylaldehyde, stir, add 5mmol of o-diphenylamine, reflux for 12h, cool, separate the solid, wash and dry to obtain catalyst B.

Embodiment 3

[0025] The preparation of the catalyst is as follows: Dissolve 3.3 g of cobalt nitrate in 30 ml of absolute ethanol, mix and stir for 30 min, add 20 ml of ethanol containing 9.85 g of 2-methylimidazole, mix and stir for 30 min, add dropwise 10 ml of ethanol solution containing 3.3 g of zinc nitrate, After mixing, stir for 30 minutes, add dropwise 1ml of formic acid solution, add 16mmol of salicylaldehyde, stir, add 9mmol of o-diphenylamine, reflux for 12h, cool, separate the solid, wash and dry to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com