A kind of preparation method and application of zno porous material with multi-core-shell structure

A technology of porous material and shell structure, applied in the analysis of materials, material resistance, microsphere preparation, etc., can solve the problems of poor selectivity, achieve the effects of increased specific surface area, low selectivity sensitivity, and enhanced gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

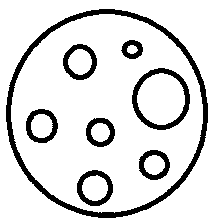

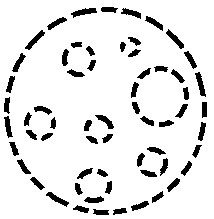

Image

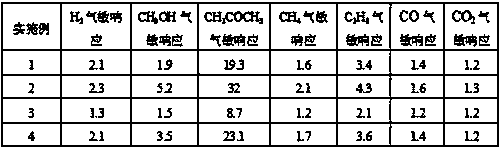

Examples

Embodiment 1

[0021] Embodiment 1 The mol ratio of zinc acetate and salicylic acid is 1.25:1

[0022] A preparation method of a ZnO porous material with a multi-core-shell structure, comprising the following steps:

[0023] Step 1, 0.137g zinc acetate dihydrate (Zn(AC) 2 2H 2 O) be dissolved in 15mL methanol solution, after magnetic stirring for 10min, ultrasonic treatment for 10min, then continue magnetic stirring for 10min, as solution A;

[0024] Step 2, 0.069g salicylic acid (C 7 h 6 o 3 ) was dissolved in methanol solution, magnetically stirred for 20min, as solution B;

[0025] Step 3, mix solution A and solution B, stir magnetically for 10 minutes, add 20 mg of polyvinylpyrrolidone (PVP) and continue stirring for 10 minutes, then transfer the mixed solution to a 50mL reaction kettle, and place the reaction kettle in an oven at 160°C for reaction After 24 hours, the reaction product was centrifuged and washed with ethanol and water for 3 times, and then dried in an oven at 60°C ...

Embodiment 2

[0027] Example 2 The molar ratio of zinc acetate and salicylic acid is 1.5:0.75

[0028] A preparation method of a ZnO porous material with a multi-core-shell structure, comprising the following steps:

[0029] Step 1, 0.164g zinc acetate dihydrate (Zn(AC) 2 2H 2 O) be dissolved in 15mL methanol solution, after magnetic stirring for 10min, ultrasonic treatment for 10min, then continue magnetic stirring for 10min, as solution A;

[0030] Step 2, 0.052g salicylic acid (C 7 h 6 o 3 ) was dissolved in methanol solution, magnetically stirred for 20min, as solution B;

[0031] Step 3, mix solution A and solution B, stir magnetically for 10 minutes, add 20 mg of polyvinylpyrrolidone (PVP) and continue stirring for 10 minutes, then transfer the mixed solution to a 50mL reaction kettle, and place the reaction kettle in an oven at 160°C for reaction After 24 hours, the reaction product was centrifuged and washed with ethanol and water for 3 times, and then dried in an oven at 60°C...

Embodiment 3

[0033] Example 3 The molar ratio of zinc acetate and salicylic acid is 1:1.25

[0034] A preparation method of a ZnO porous material with a multi-core-shell structure, comprising the following steps:

[0035] Step 1, 0.109g zinc acetate dihydrate (Zn(AC) 2 2H 2 O) be dissolved in 15mL methanol solution, after magnetic stirring for 10min, ultrasonic treatment for 10min, then continue magnetic stirring for 10min, as solution A;

[0036] Step 2, 0.086g salicylic acid (C 7 h 6 o 3 ) was dissolved in methanol solution, magnetically stirred for 20min, as solution B;

[0037] Step 3, mix solution A and solution B, stir magnetically for 10 minutes, add 20 mg of polyvinylpyrrolidone (PVP) and continue stirring for 10 minutes, then transfer the mixed solution to a 50mL reaction kettle, and place the reaction kettle in an oven at 160°C for reaction After 24 hours, the reaction product was centrifuged and washed with ethanol and water for 3 times, and then dried in an oven at 60°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com