Mercury-free catalyst, preparation method thereof and application to preparation of chloroethylene

A mercury catalyst and catalyst technology, applied in the chemical industry, can solve the problems of high cost of gold catalysts, and achieve the effects of high cost, good activity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 The acquisition of carrier

[0042] 13X molecular sieve (SiO 2 / Al 2 o 3 =2.25) The original powder was purchased from Jiangsu Aoshi Technology Co., Ltd.

[0043] Na-USY(SiO 2 / Al 2 o 3 =9.47) was purchased from Nankai Catalyst Factory.

[0044] Li-X molecular sieves were prepared by the following method: 1g 13X molecular sieves were added to 500mL of 1M lithium nitrate solution, stirred at 60°C for 2 hours, after centrifugation, exchanged twice, and the obtained solid was centrifuged and washed with deionized water for 3 Once, dry at 120°C for 6 hours to obtain Li-X molecular sieve.

[0045] H-X molecular sieves were prepared by the following method: 1g 13X molecular sieves were added to 500mL of 1M ammonium nitrate solution, stirred at 60°C for 2 hours, after centrifugation, repeated exchange 2 times, the obtained solid was centrifuged, washed 3 times with deionized water, Dry at 120°C for 6 hours and calcinate at 550°C for 4 hours to obtain H-X m...

Embodiment 2

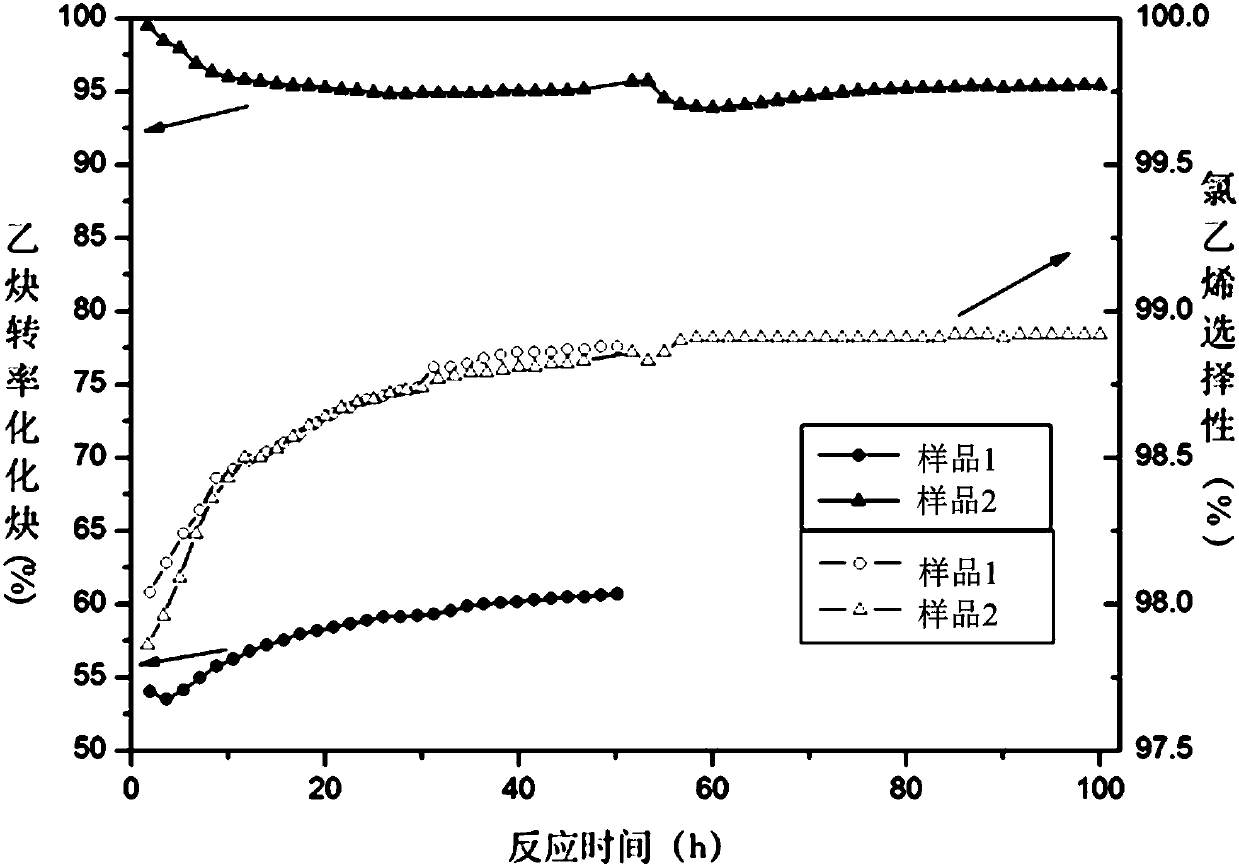

[0048] Example 2 Sample 1 # preparation of

[0049] Weigh 1.50g anhydrous copper chloride (CuCl 2 ) in a beaker, add 4.97g deionized water to dissolve and stir evenly. Weigh 10g 13X molecular sieve raw powder (SiO 2 / Al 2 o 3 =2.25), the above solution was added to the original powder of 13X molecular sieve, stirred evenly, dried at room temperature for 12 hours, dried at 100°C for 12 hours, and then dried for 1 hour under nitrogen purging to obtain a mercury-free catalyst with a copper chloride loading of 15%. , denoted as sample 1 # .

Embodiment 3

[0050] Example 3 Sample 2 # preparation of

[0051] Weigh 3.17g copper chloride dihydrate (CuCl 2 .2H 2 O) In a beaker, add 4.73g of dehydrated ethanol to dissolve and stir evenly. Weigh 10g of 13X molecular sieve raw powder, add the above solution into 13X molecular sieve raw powder, stir evenly, dry at room temperature for 12 hours, dry at 120°C for 12 hours, and then dry under nitrogen purging for 1 hour to obtain a copper chloride loading capacity of 25%. The mercury-free catalyst, denoted as sample 2 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com