Two-section type switchable tubular reactor and method for preparing alcohol through aldehyde gas phase hydrogenation by using same

A tube reactor and reactor technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as gas-phase raw material deviation flow, increase in tube pressure difference, and short operating life of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

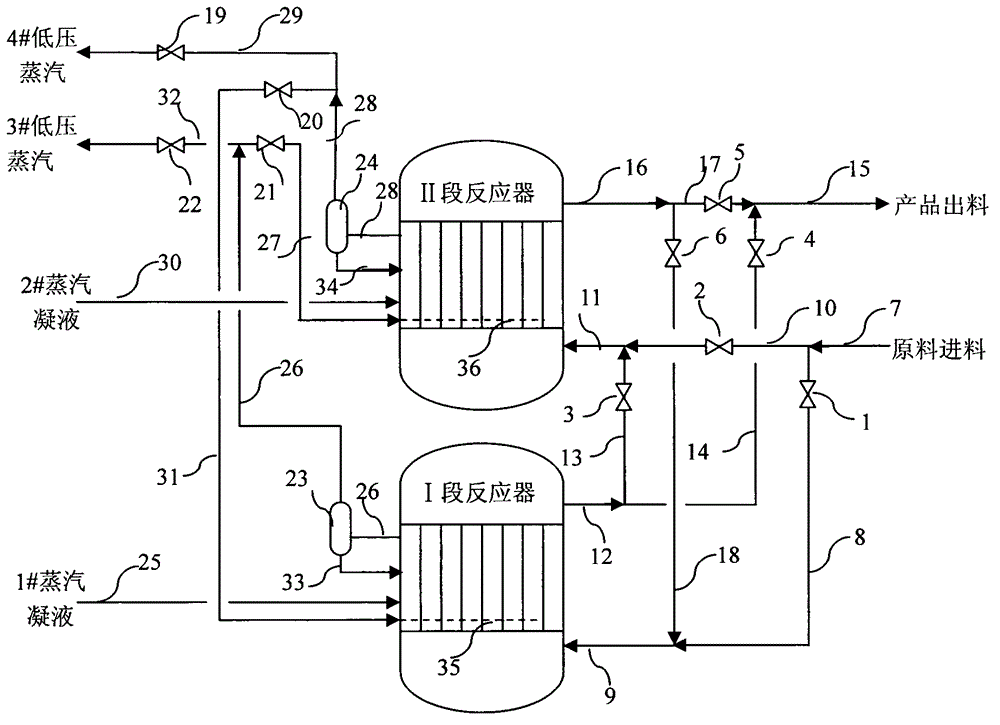

[0073] The embodiment adopts such as figure 1 The two-stage switchable tubular reactor shown includes stage I reactor, stage II reactor, valves and pipelines of the reaction material system, valves and pipelines of the temperature control system, and the way of connecting the valves and pipelines of the reaction material system is as follows:

[0074] Raw material feed main pipe 7, feed pipe a8, stage I reactor feed main pipe 9, I stage reactor, I stage reactor discharge main pipe 12, discharge pipe c13, II stage reactor feed main pipe 11, II stage Reactor, stage II reactor discharge main pipe 16, discharge pipe e17, and product discharge main pipe 15 are connected in sequence, wherein the first valve 1 is installed on the feed pipe a8, and the feed main pipe 9 of the I-stage reactor is connected to the I section At the bottom of the tube side of the reactor, the discharge main pipe 12 of the stage I reactor is connected to the top of the tube side of the I stage reactor, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com