Fiber and polytetrafluoroethylene plate rubber combined shock insulation support

A technology of polytetrafluoroethylene board and seismic isolation support, which is applied in the field of seismic isolation of housing construction, and can solve the problems of self-heavy, high cost, and poor earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

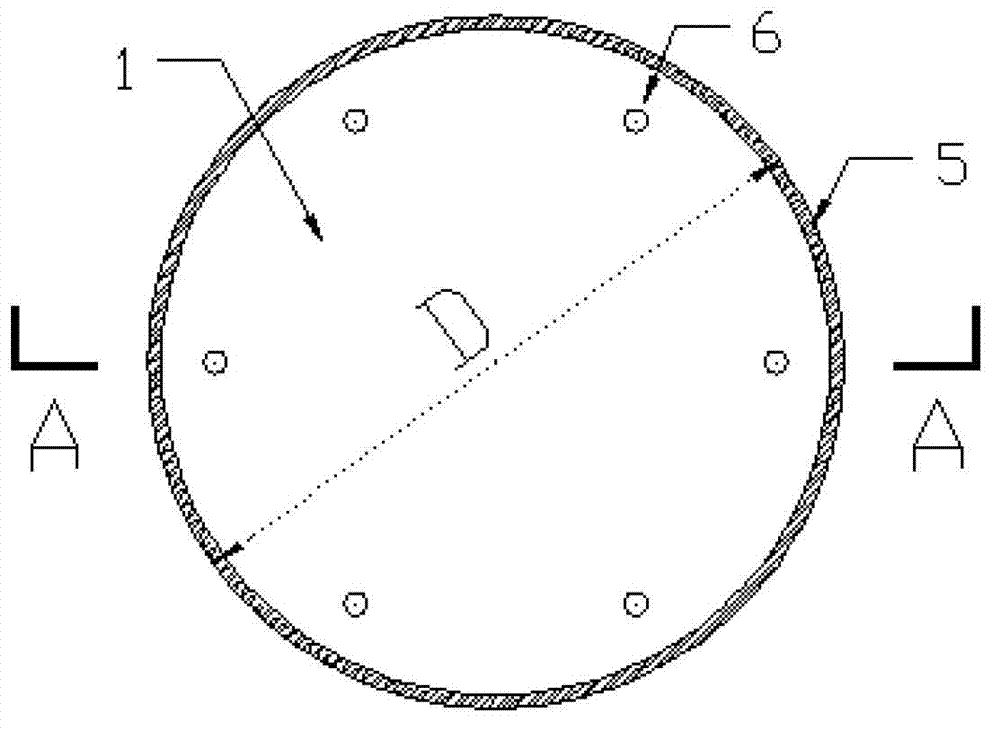

[0018] Such as figure 1 and figure 2 As shown, a fiber-polytetrafluoroethylene plate rubber composite shock-absorbing support, the support consists of three parts: rubber layer 2, polytetrafluoroethylene plate 3 and fiber layer 4. The stacking sequence is as follows: rubber layer 2, polytetrafluoroethylene plate 3, rubber layer 2, fiber layer 4, rubber layer 2, stacking several layers in this order and finally ending with the rubber layer to form a laminated body, and then in the laminated body The upper and lower end surfaces of the composite body are respectively added with end steel plates 1, and a rubber protective layer 5 is added around the side of the composite body, and finally vulcanized and bonded.

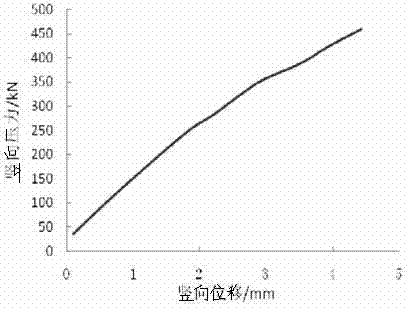

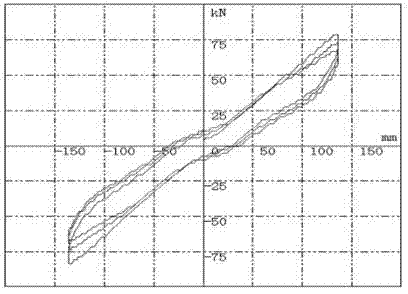

[0019] In this embodiment, 35 layers of seismic isolation bearings are stacked together, including 17 layers of reinforcement layers, including 9 layers of polytetrafluoroethylene board layers and 8 layers of fiber layers. While reducing the self-weight, the energy d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com