Pneumatic motor

A technology of air motor and exhaust flow, applied in machine/engine, rotary piston engine, rotary or oscillating piston engine, etc., can solve the limitation of the number of blades of air motor, the torque efficiency is not significantly improved, and the torque cannot be stabilized Output and other issues to achieve the effect of improving torque efficiency and output torque efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following examples are only used to illustrate possible implementation modes of the present invention, and are not intended to limit the protection scope of the present invention.

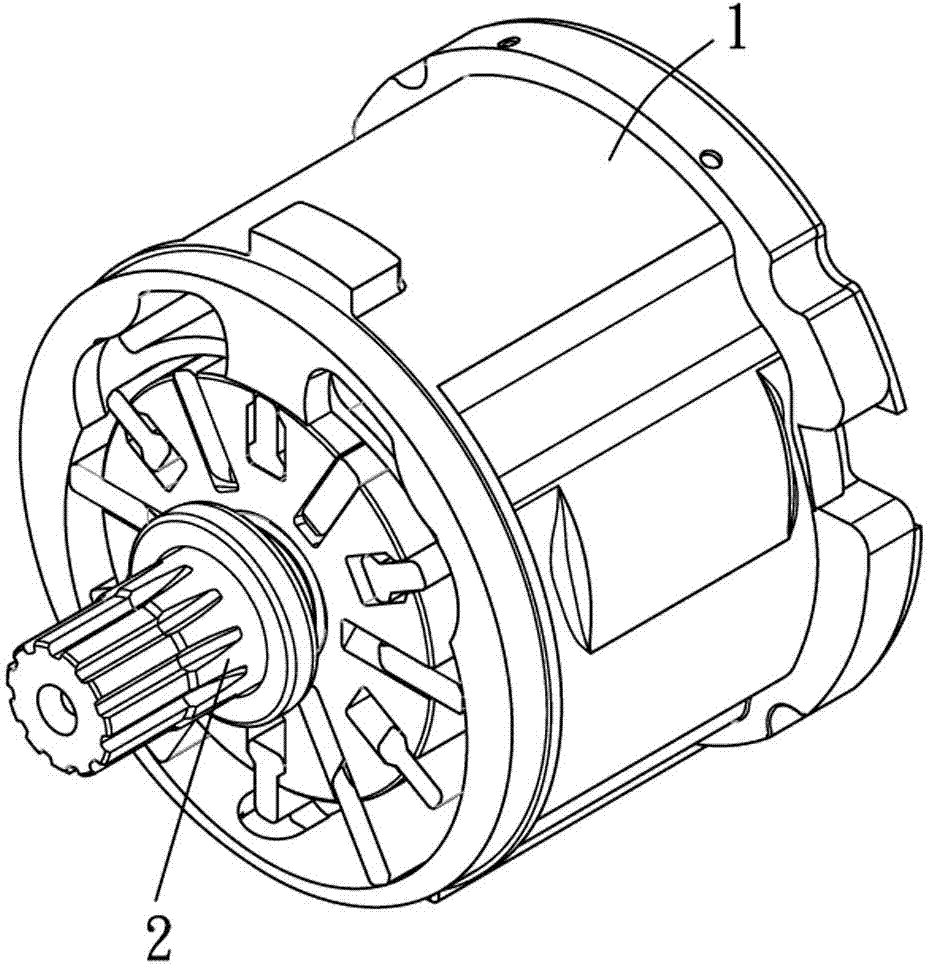

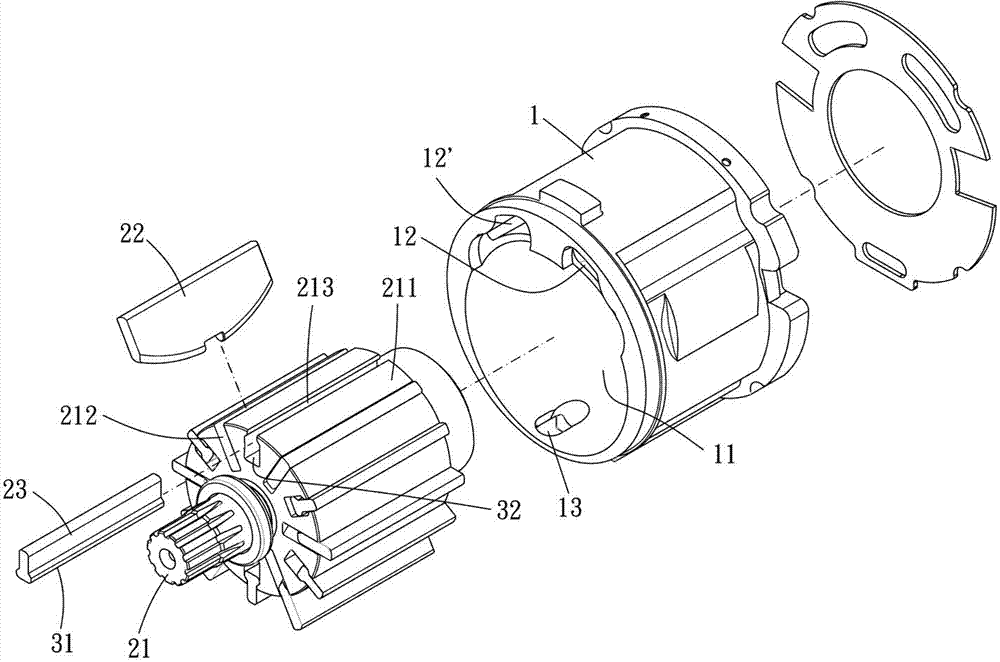

[0038] Please refer to figure 1 and figure 2 , The present invention provides an air motor, which is installed in various air tools and driven by high-pressure gas to further drive the air tools to work. The air motor provided by the present invention includes a cylinder 1, a rotor 2 and a limiting device.

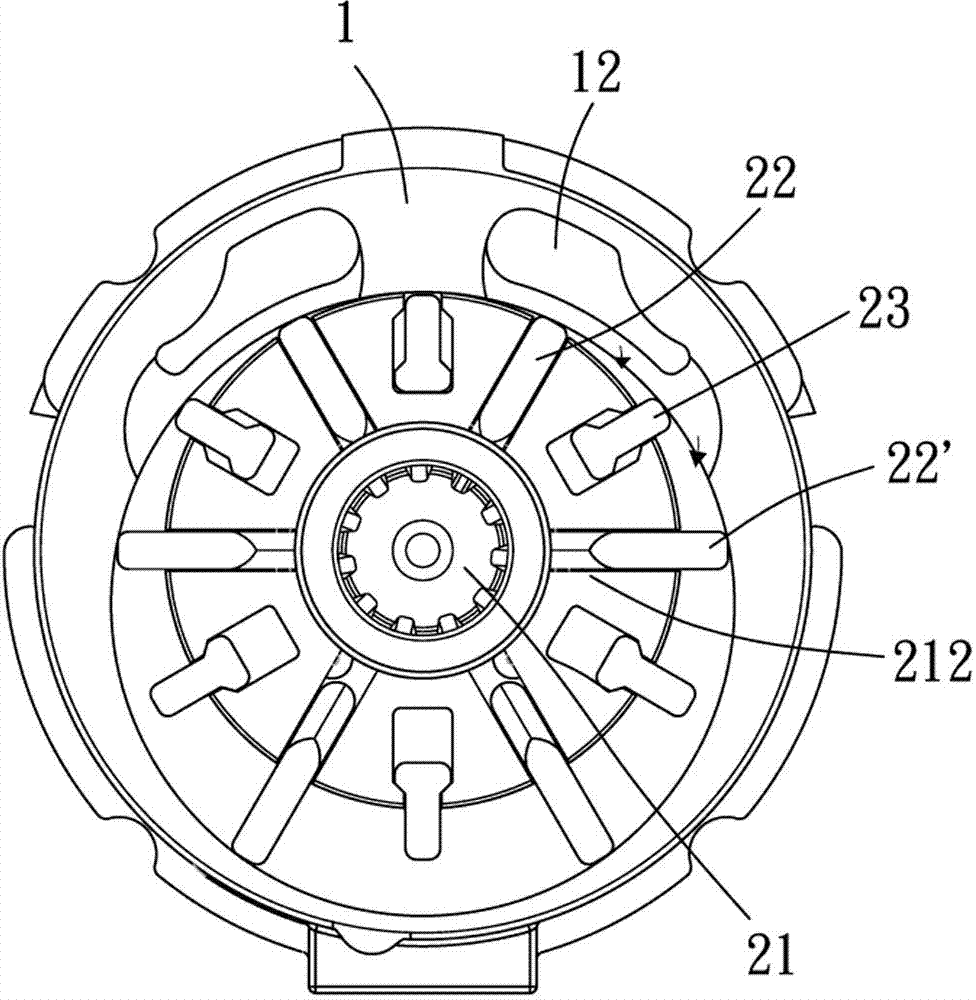

[0039] The cylinder 1 is surrounded by an accommodating groove 11 , an intake flow passage 12 and an exhaust flow passage 13 , and the intake flow passage 12 and the exhaust flow passage 13 communicate with the accommodating groove 11 respectively. The cylinder 1 has an inner wall, which is located on the peripheral surface of the housing tank 11. Through this structural design, high-pressure gas can enter the housing tank from the outside through the intake channel 12, and then b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com