Totally closed hydraulic oil tank

A hydraulic oil tank, fully enclosed technology, applied in the direction of oil supply tank devices, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve problems such as hydraulic oil pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

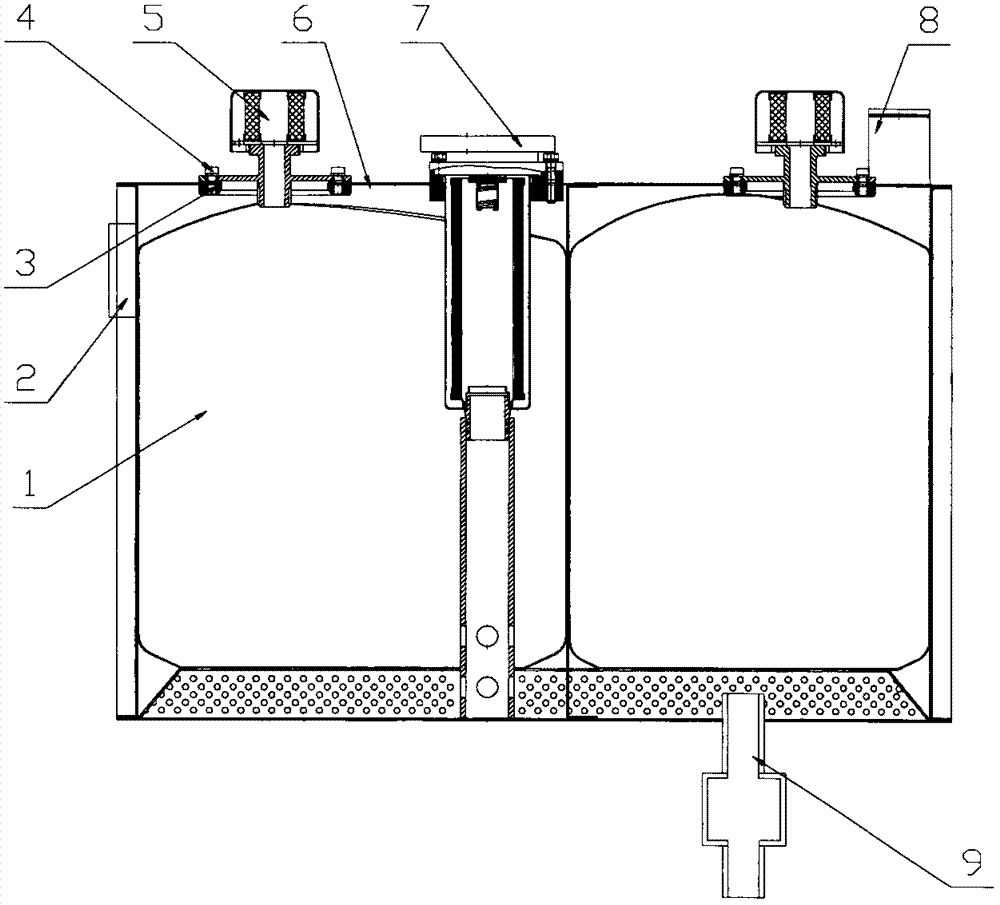

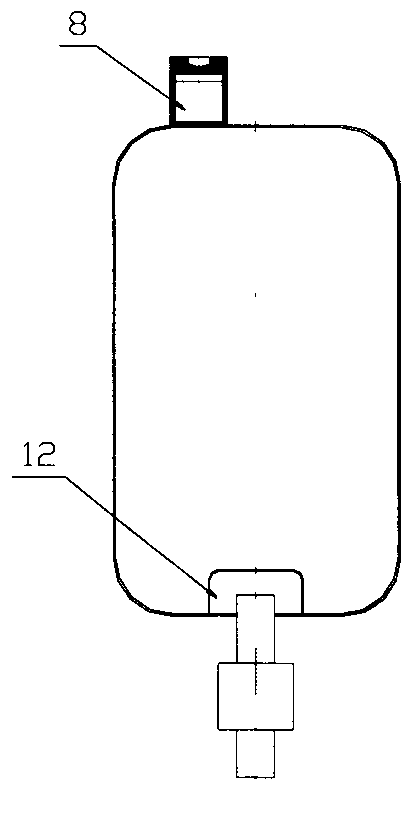

[0014] Embodiment 1, the described oil-gas isolation device 1 is used as a kind of fully enclosed hydraulic oil tank of the gas storage container (see attachment figure 1 to attach Figure 5 ), which includes an oil storage tank 6, an oil-gas isolation device 1, a guide sleeve 3, an oiler 8, an oil outlet pipe 9, an oil return filter 7, and a diversion device 12; the oil-gas isolation device 1 includes an air nozzle 14 Composed of an air bag 13, the air bag 13 is loaded into the oil storage tank 6 through the guide sleeve 3, the middle part of the air nozzle 14 is provided with a large flange 16 connected to the air nozzle, the outside is provided with an outer connection port 15 of the air nozzle, and an air nozzle is provided inside Passage 18, air nozzle sealing tube 17 is connected with air bag 13, the material of said air bag 13 includes oil-resistant rubber, can freely compress and expand volume; air bag 13 outlet and mouth sealing tube 17 are pasted together, through ai...

Embodiment 2

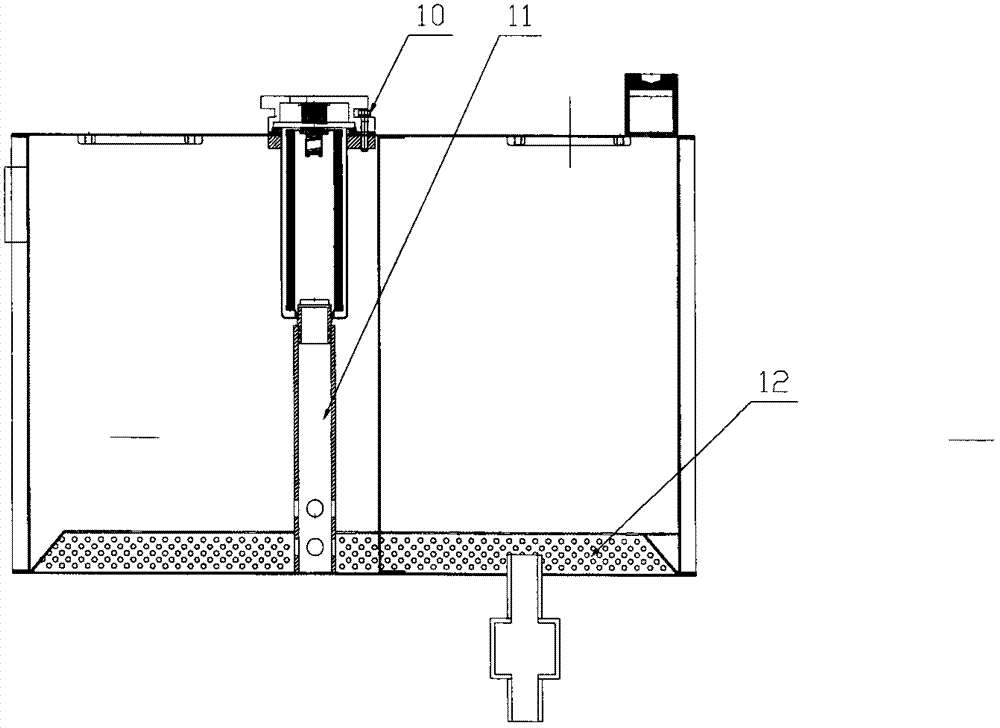

[0015] Embodiment 2, the described oil and gas isolation device is used as a kind of fully enclosed hydraulic oil tank of the oil storage container (see the attachment figure 2 To accompanying drawing 7), it comprises oil storage tank 6, oil-gas isolating device 1, oiler 8, oil outlet pipe 9, return oil filter 7, diversion device two 22 to form; Described oil-gas isolating device 1 passes guide sleeve 3 Put the airbag 13 into the oil storage tank 6, the air nozzle is connected to the large flange 16 and installed on the bottom of the oil storage tank 6 through the bolt 4; the above-mentioned refueling cylinder 20 is directly welded on the pipe 23; the above-mentioned flow guiding device Two 22 are provided with an oil return port 29, an oil inlet 30, an oil filling pipe 23, and an oil outlet 27; the oil outlet pipe 8 is directly welded on the oil outlet 27, and the refueling cylinder 20 is welded on the oil pipe 22 , sealed by a large screw plug 19; the short gas outlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com