Device for introducing cooling water to chilled water circulation system in polyester device

A technology of cooling water and chilled water, which is applied in the field of polyester equipment, can solve problems such as waste of energy resources, no interchangeability, and inability to switch between each other, and achieve the effect of reducing operating costs and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

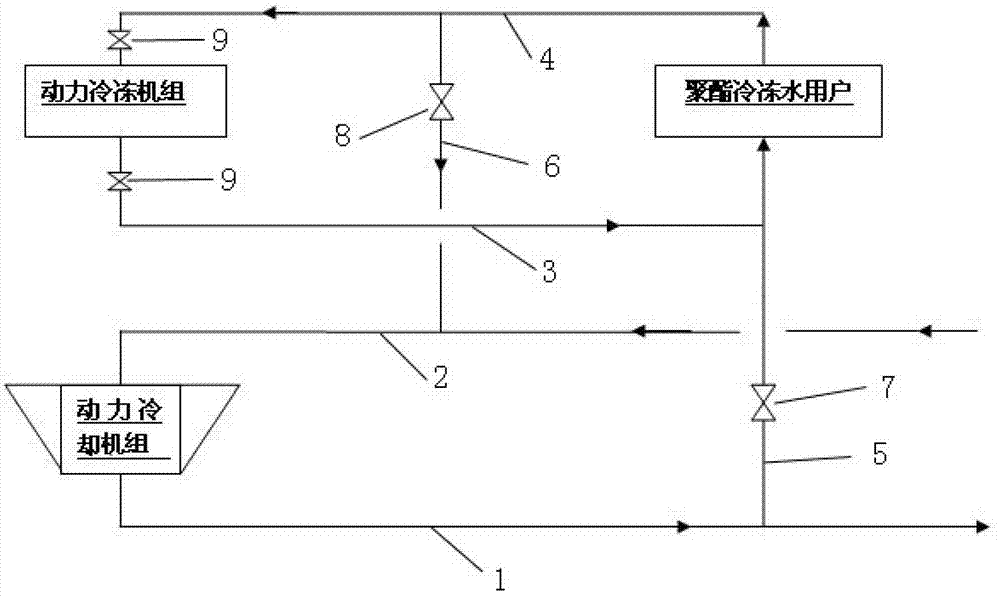

[0015] Such as figure 1 As shown, the present invention provides a device for introducing cooling water into a chilled water circulation system in a polyester plant, comprising a cooling water outlet pipeline 1, a cooling water return pipeline 2, a chilled water outlet pipeline 3 and a chilled water return pipeline 4. The cooling water outlet pipeline 1 is connected to the chilled water outlet pipeline 3 through a first pipeline 5, and the cooling water return pipeline 2 is connected to the chilled water return pipeline 4 through a second pipeline 6. The first pipeline 5 is provided with a first valve 7 , and the second pipeline 6 is provided with a second valve 8 . Preferably, the first valve 7 and the second valve 8 are butterfly valves, the cooling water outlet pipe 1 and the first pipe 5, the chilled water outlet pipe 3 and the first pipe 5, the cooling water return pipe The water pipeline 3 and the second pipeline 6, the chilled water return pipeline 4 and the second pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com