Double limited self-locking ball screen

A self-locking, ball net collection technology, applied in the field of heat exchanger cleaning, can solve problems such as difficult to detect, unreasonable structure, excessive transmission, etc., and achieve the effect of stable work, simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

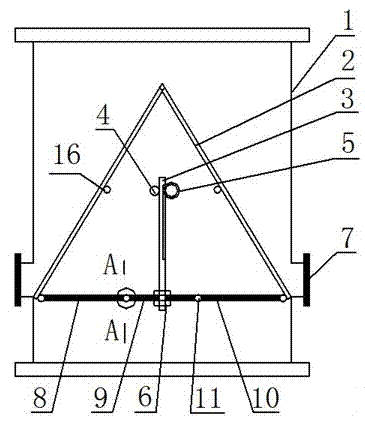

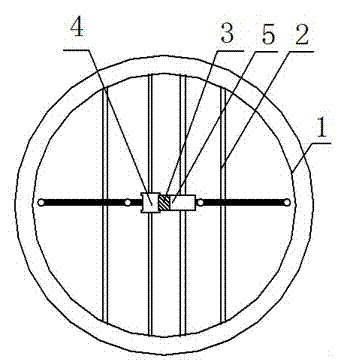

[0013] Embodiment 1: The connecting rod II9 in the three-link driving device is connected to the rack 3 through the installation hole, the bottom of the rack 3 passes through the connecting rod II9 and is threaded to the lock nut 6, and the toothed side of the rack 3 meshes The gear 5 and the toothless side of the rack 3 are in contact with the positioning roller 4. In this way, when the rack 3 moves up and down under the drive of the gear 5, the positioning roller 4 can be used to determine the longitudinal position of the rack 3 and ensure Under various working conditions, the gear 5 and the rack 3 are tightly meshed. During design, the setting of the number of teeth of the gear 5 and the number of teeth of the rack 3 is completed in such a way: when the ball collecting net is in the ball collecting working condition, the gear 5 reaches the top of the rack 3; Under normal circumstances, the gear 5 arrives at the bottom of the rack 3; Through this kind of design, it can prev...

Embodiment 2

[0016] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the structure of the rack 3 is changed, so that both sides of the rack 3 have protruding teeth, so that the teeth on both sides can mesh with the gear 5 , the transmission life of the double-sided structure rack 3 is greatly extended, and the transmission carrying capacity is also increased at the same time, and the transmission is more stable and smooth.

Embodiment 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 is that a screw transmission mechanism is used to complete the driving of the three linkages, and realize the conversion of the three working conditions of the ball net. The connecting rod II 9 is connected with a rotating screw 14 through the mounting hole, the bottom of the rotating screw 14 is threaded with the locking nut 6, and the rotating screw 14 is also threaded with a fixed nut. Also be provided with protective cover 15 on this screw transmission. In this way, when the rotating screw rod 14 is driven by external force to rotate, through the screw transmission, the connecting rod II9 is driven upward, and moves to the backwashing working condition or the non-commissioning state.

[0018] In the above-mentioned embodiment, a limit block 12 can be provided at an appropriate position on the side of the movable limit card slot 11, and the installation of the limit block again limits the accurac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com