Printer charging unit

A technology for charging devices and printers, applied to corona discharge devices, circuits, electrical components, etc., can solve problems such as harmful to human body, high voltage, etc., and achieve the effects of easy processing, improved service life, and avoiding wear and tear problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

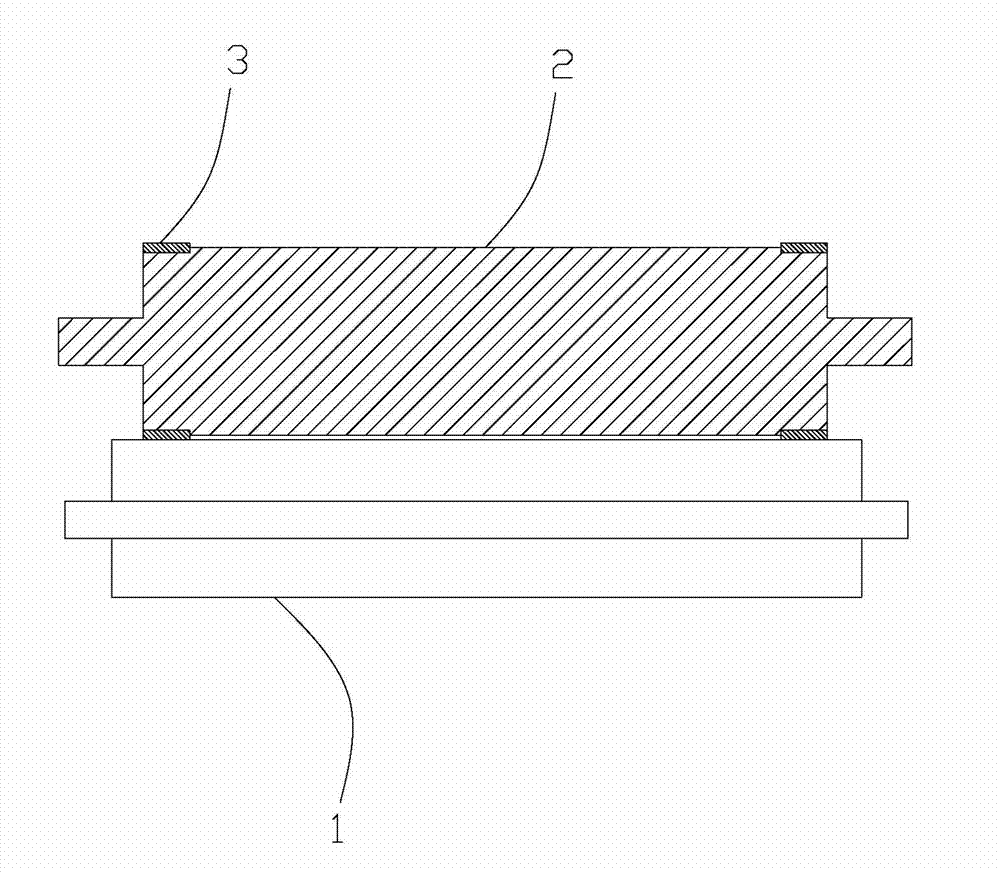

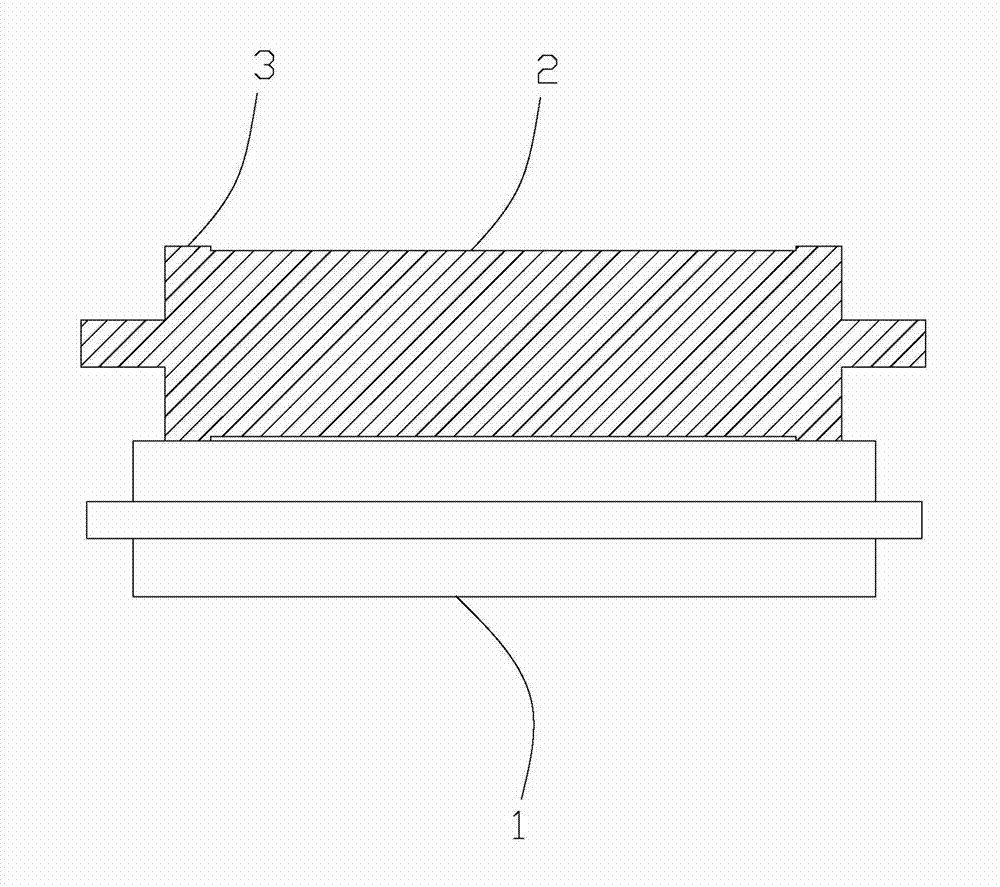

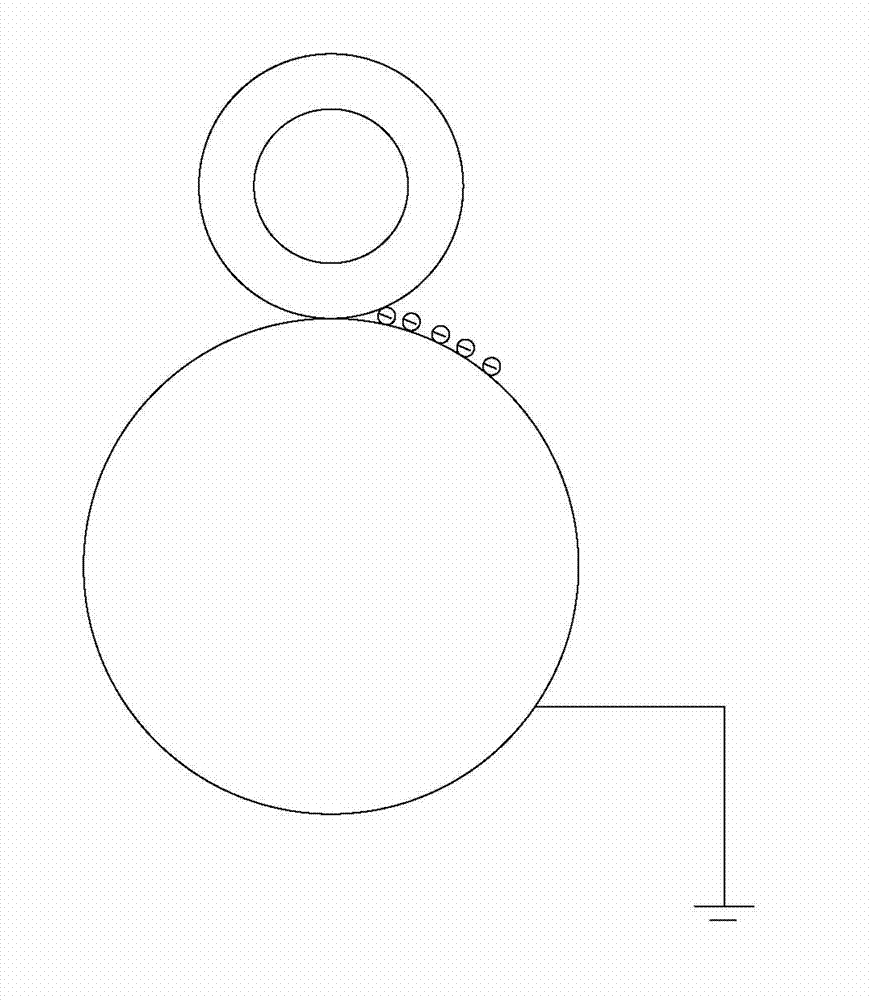

[0022] refer to Figure 1 to Figure 2 , the invention discloses a charging device for a printer, comprising a compression spring device and a charging roller 2 arranged in a gap with a photosensitive drum 1. The gap setting means that the photosensitive drum 1 and the charging roller 2 maintain a certain distance, and the photosensitive drum 1 and the charging The distance d between the rollers 2 is 0<d<0.1mm. As a preferred implementation distance of the present invention, the distance d between the photosensitive drum 1 and the charging roller 2 is preferably d=0.02mm. At this distance, the charging effect is good , and the processing accuracy is easy to grasp. In this application, the charging roller can be a metal charging roller or a conductive plastic charging roller or a conductive resin charging roller, and the conductive resin can be epoxy resin or urea-formaldehyde resin.

[0023] As shown in the figure, the two ends of the charging roller 2 are provided with a gap s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com