Water-based coating composition and process for formation of coating film

A technology of water-based coatings and compositions, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as difficult to carry out and difficult to form coating films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

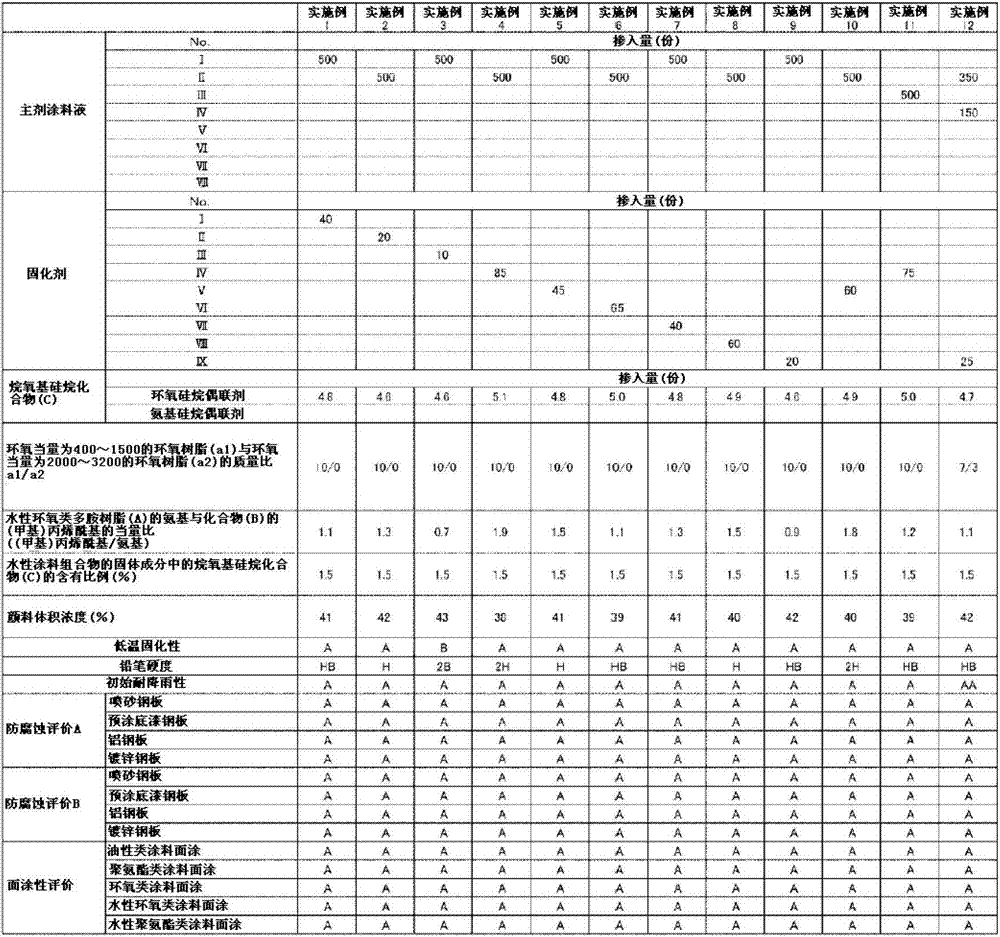

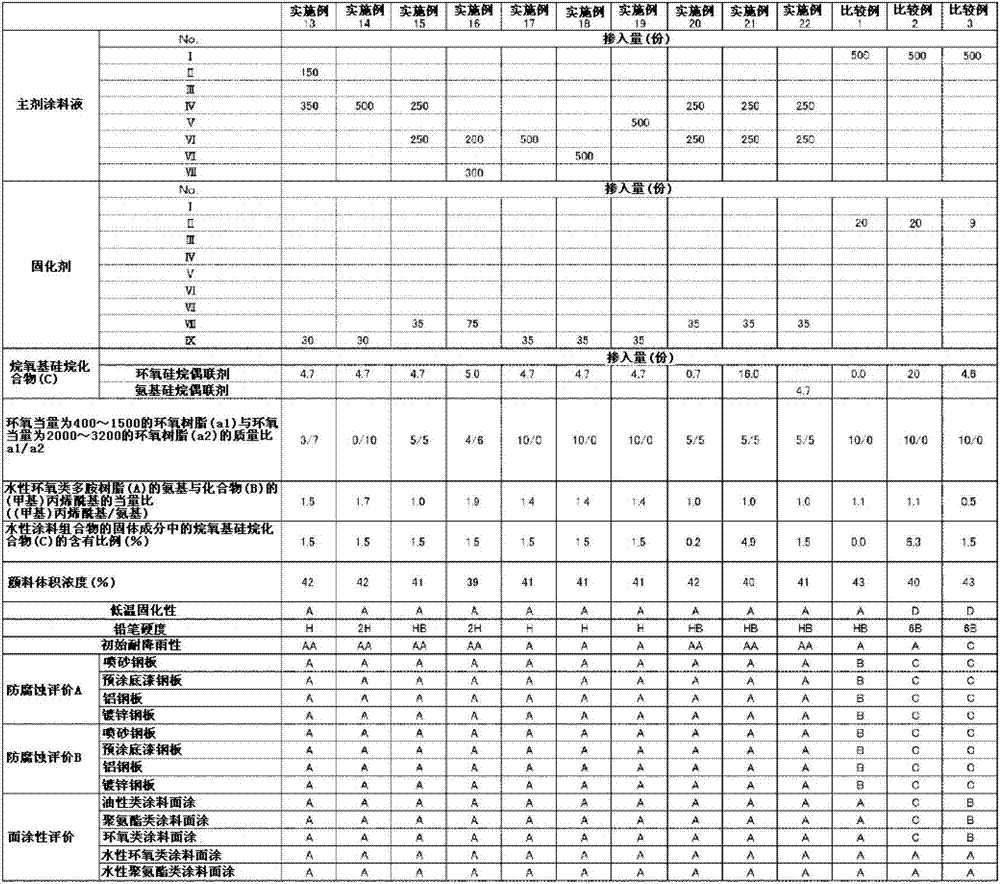

Examples

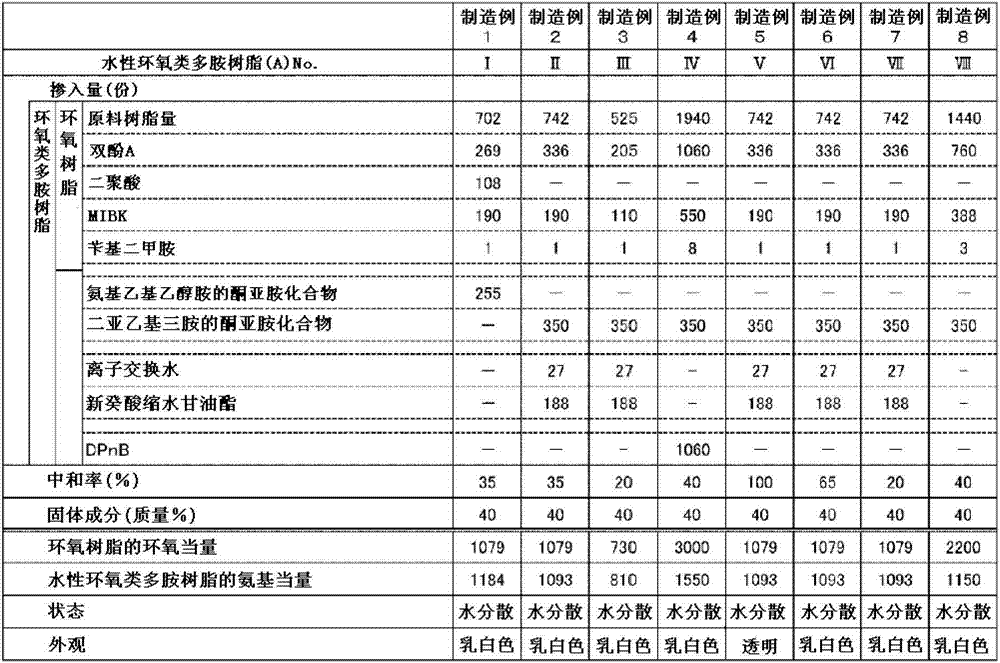

manufacture example 1

[0096] [Manufacturing example 1] Preparation of water-based epoxy polyamine resin (A) Ⅰ

[0097] Add 702 parts of raw material resin, 269 parts of bisphenol A, 108 Parts of dimer acid, 190 parts of methyl isobutyl ketone (hereinafter referred to as "MIBK"), in the presence of 1 part of benzyldimethylamine, reacted at 117°C until the epoxy equivalent reached 1079g / equivalent, Thus an epoxy resin is obtained. Then, 255 parts of ketimine compounds (73 mass % MIBK solution) of aminoethylethanolamine were added, and it was made to react at 117 degreeC for 1 hour. Then, it diluted with MIBK to 75% of non-volatile content, and obtained the epoxy-type polyamine resin whose amino group equivalent weight is 1184.

[0098] Here, acetic acid was added so that the neutralization rate would be 35.0% (neutralization rate with respect to the amino groups of the resin), and ion-exchanged water was added for dilution. Then, the mixture of MIBK and water was removed under reduced pressure so ...

manufacture example 2

[0099] [Production Example 2] Production of Waterborne Epoxy Polyamine Resin (A) II

[0100] Add 742 parts of raw material resin, 336 parts of bisphenol A, 190 One part of MIBK was reacted at 117° C. in the presence of one part of benzyldimethylamine until the epoxy equivalent reached 1079 g / equivalent, thereby obtaining an epoxy resin. Then, 350 parts of ketimine compounds (73 mass % MIBK solution) of diethylenetriamine were added, and it was made to react at 117 degreeC for 1 hour. Then, 27 parts of ion-exchanged water and 188 parts of glycidyl neodecanoate (manufactured by Hexion Specialty Chemicals, trade name "Cardura E10-P") were added, and reacted at 100°C for 2 Hour. Then, it diluted with MIBK to 75% of non-volatile content, and obtained the epoxy-type polyamine resin whose amino group equivalent weight is 1093.

[0101] Here, acetic acid was added so that the neutralization rate would be 35.0% (neutralization rate with respect to the amino groups of the resin), and...

manufacture example 3

[0102] [Production example 3] Production of water-based epoxy polyamine resin (A) III

[0103] Add 525 parts of raw material resin, 205 parts of bisphenol A, 110 parts of epoxy equivalent obtained by synthesizing bisphenol A and epichlorohydrin in the reaction tank equipped with agitator, cooler, nitrogen introduction pipe and thermometer. One part of MIBK was reacted at 117° C. in the presence of one part of benzyldimethylamine until the epoxy equivalent reached 730 g / equivalent, thereby obtaining an epoxy resin. Then, 350 parts of ketimine compounds (73 mass % MIBK solution) of diethylenetriamine were added, and it was made to react at 117 degreeC for 1 hour. Then, 27 parts of ion-exchanged water and 188 parts of glycidyl neodecanoate (manufactured by Hexion Specialty Chemicals, trade name "Cardura E10-P") were added and reacted at 100° C. for 2 hours. Then, it diluted with MIBK to 75% of non-volatile content, and obtained the epoxy-type polyamine resin whose amino group eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com