Two-stage fuel injection valve for a diesel engine, comprising a solenoid valve and a shuttle valve

A technology for diesel engines and fuel injection valves, applied in fuel injection devices, engine components, machines/engines, etc., can solve problems such as inability to determine injection timing, achieve good combustion performance, optimize spray shape, and improve fuel consumption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

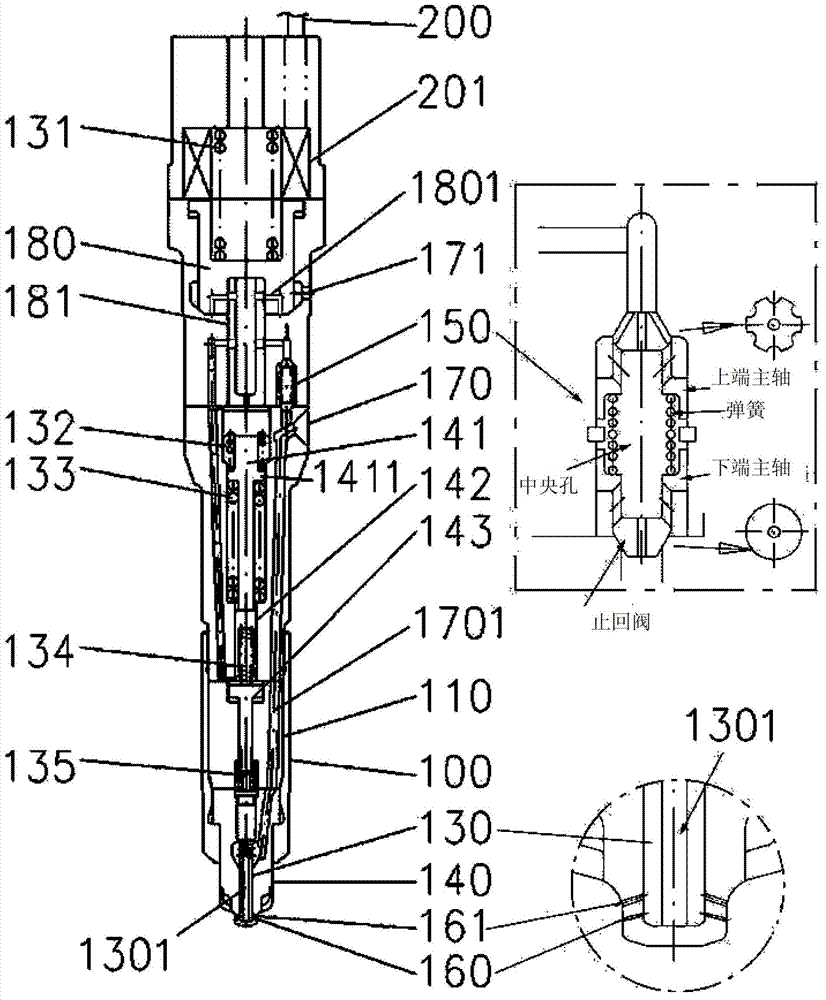

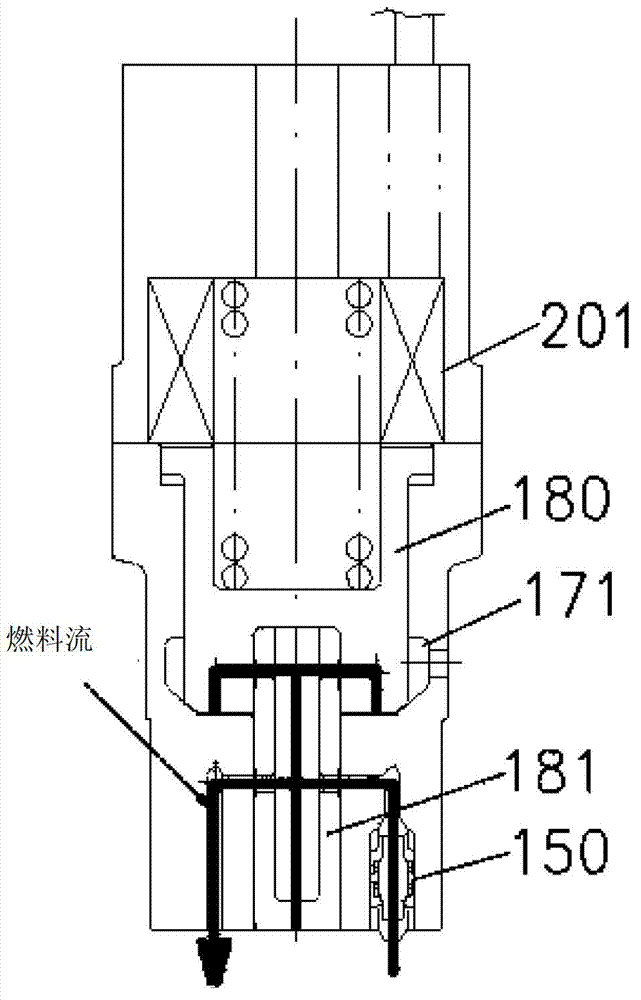

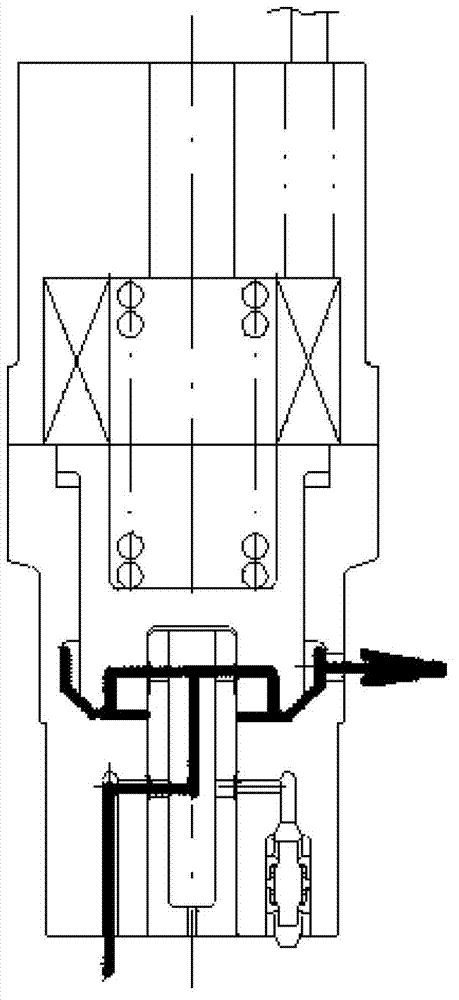

[0062] The configuration and functions of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In addition, in the description of the present invention, when it is judged that a well-known function or a detailed description of a configuration may obscure the gist of the present invention, its detailed description will be omitted.

[0063] figure 1 is a schematic cross-sectional view of a fuel injection valve according to the present invention, figure 2 is an embodiment according to the invention of supplying pressure to the booster at low load pressures before solenoid valve activation when not injecting, image 3 It is a cross-sectional schematic diagram of the solenoid valve starting to discharge the relative pressure of the booster. Figure 4 is a schematic cross-sectional view showing an embodiment of the first fuel injection, Figure 5 is a schematic cross-sectional view showing a second fuel injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com