Axial flow wind wheel, manufacturing method of axial flow wind wheel and air treating device

A manufacturing method and axial flow wind technology, applied in the field of air purification, can solve the problems of high motor power, high noise and high power consumption, and achieve the effects of low power consumption, low noise and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

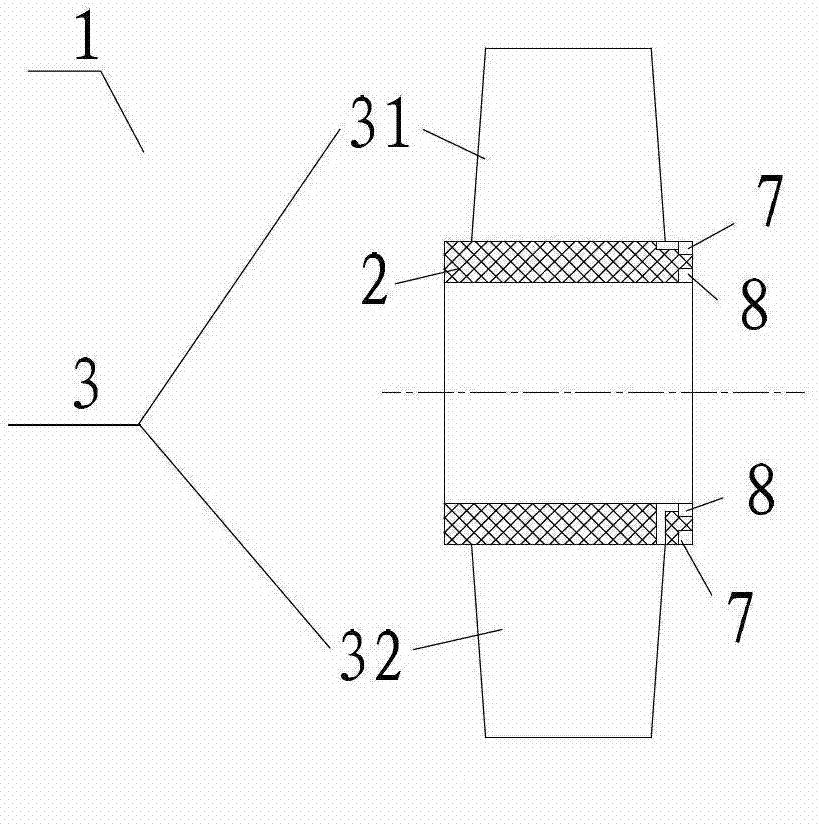

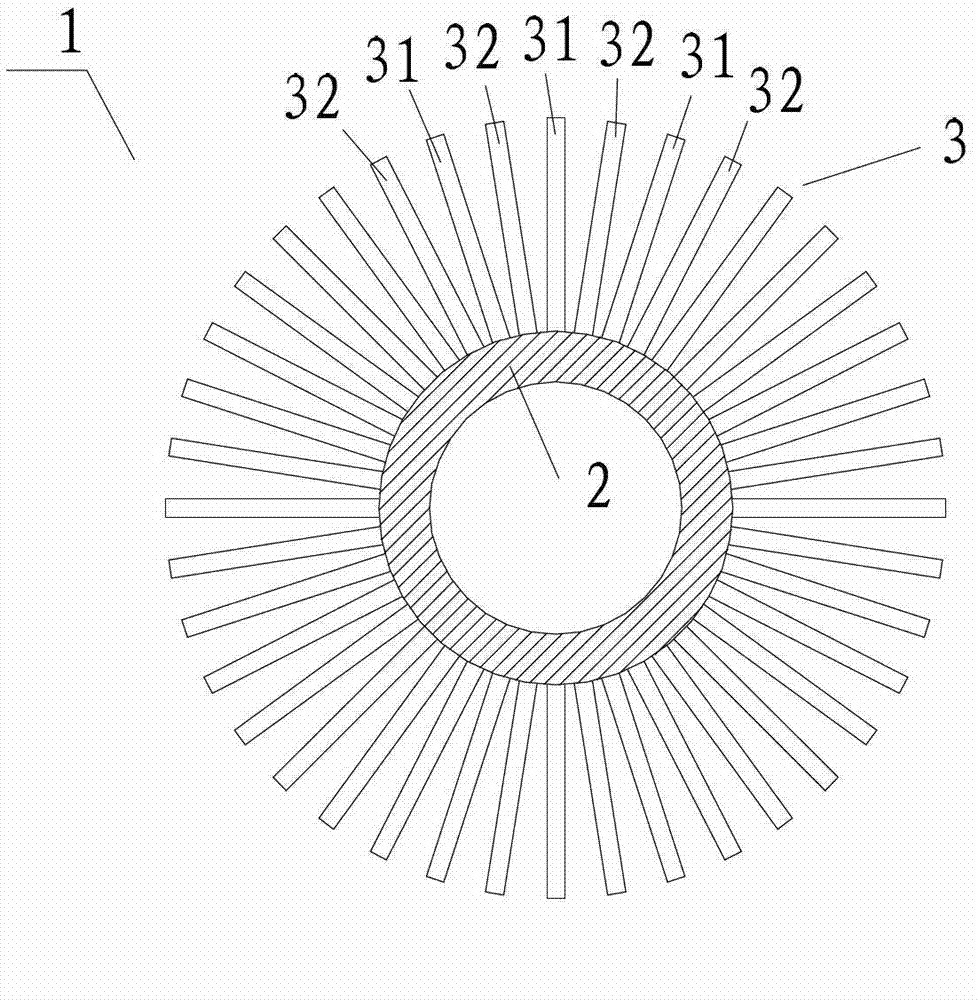

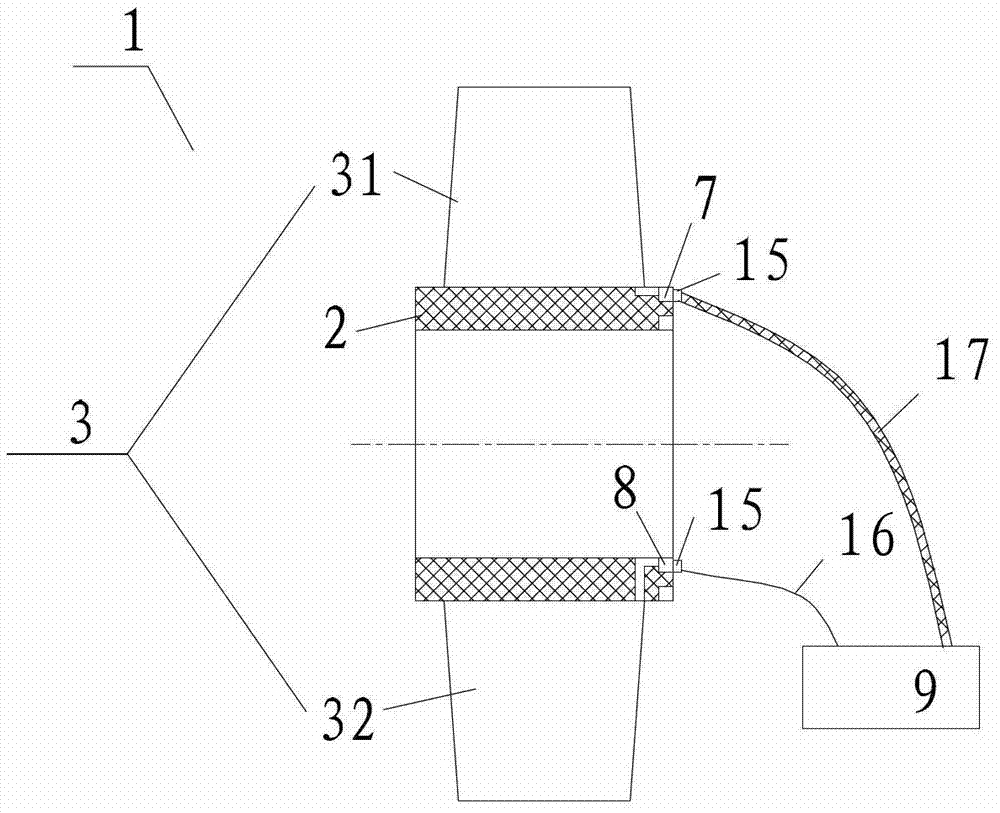

[0064] see Figures 1 to 3 , figure 1 It is a schematic diagram of the vertical cross-sectional structure of the axial flow wind wheel in one embodiment of the present invention; figure 2 for figure 1 Schematic diagram of the left view structure of the axial flow wind wheel, image 3 for figure 1 Schematic diagram of the connection structure of the axial flow wind wheel. refer to figure 1 and figure 2 , in the embodiment of the present invention, the axial wind rotor 1 includes a hub 2 and blades 3 . The blades 3 are fixed on the outer cylindrical surface of the hub 2 at certain intervals. The blades 3 include a first group of blades 31 and a second group of blades 32 , the two groups of blades are interlaced with each other, both have conductive properties but are insulated from each other, and the two grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com