Method for detecting rolling forces during medium plate rolling process

A rolling process and detection method technology, applied in the direction of metal rolling, metal rolling, length measuring device, etc., can solve the problems of restricting rolling production, failure to restore, long maintenance cycle, etc., to achieve continuous production and improve Measuring range, effect of saving purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

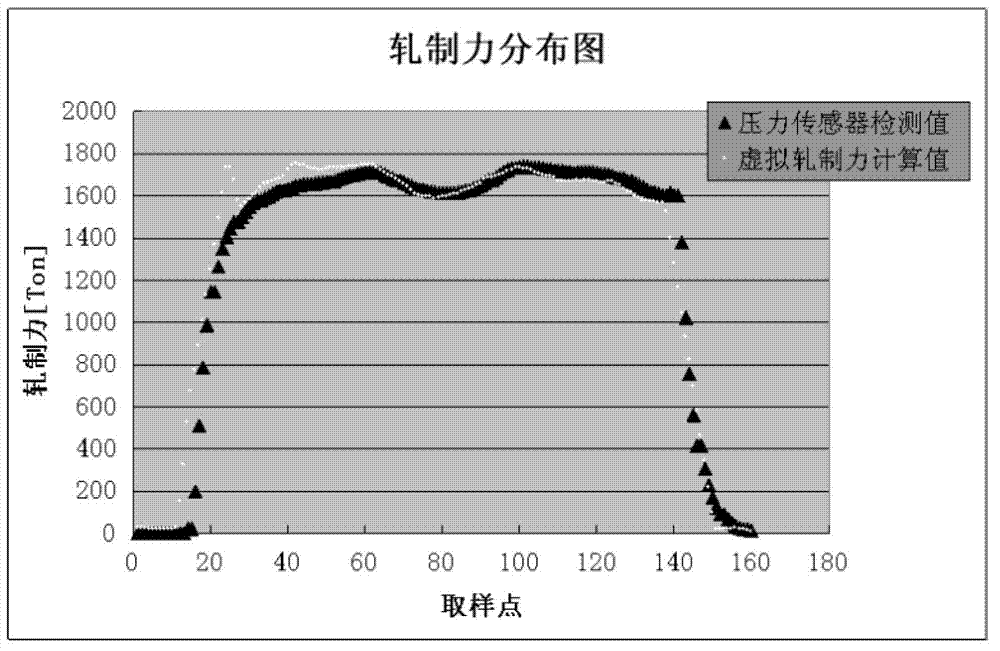

[0022] A method for detecting rolling force in the rolling process of medium and heavy plates, the method realizes the detection of rolling force through indirect detection, and includes the following steps:

[0023] (1) Manually confirm the contact signal of the work roll, which is carried out by deforming the lead wire, and use this signal to trigger recording and store the extension value of the pressing displacement sensor, so as to ensure the successful zeroing of the roll gap calibration;

[0024] (2) Through the data acquisition system (by the main motor control cabinet of the roughing mill), real-time and uninterrupted collection of relevant motor state parameters such as voltage and current, sampling the instantaneous voltage and current of the motor, and passing the collected state parameters through Profibus The field bus is sent to AMS (programmable controller), and then the output work of the motor is calculated according to the formula W=U×I×t and the state parame...

Embodiment 2

[0040] (1) Manually confirm the contact signal of the work roll. The manual confirmation of the work roll contact is carried out in the virtual pressing mode. The virtual pressing mode is based on the successful pressing of the previous time. Calculate the extension value of the displacement sensor at the zero point of the roll gap, and after clicking the compaction button to confirm, record and store the extension value of the displacement sensor to ensure that the roll gap calibration and zero adjustment is successful;

[0041] (2) Through the data acquisition system (by the main motor control cabinet of the roughing mill), real-time and uninterrupted collection of relevant motor state parameters such as voltage and current, sampling the instantaneous voltage and current of the motor, and passing the collected state parameters through Profibus The field bus is sent to AMS (programmable controller), and then the output power of the motor is calculated according to the formula ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com