Cutting mechanism of bidirectional planing machine

A cutting mechanism and two-way planing technology, which is applied in the direction of planer, planer/slotting machine, metal processing equipment, etc., can solve the problem that the surface processing quality of workpieces is difficult to improve, and achieve the effect of simple structure, convenient operation and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

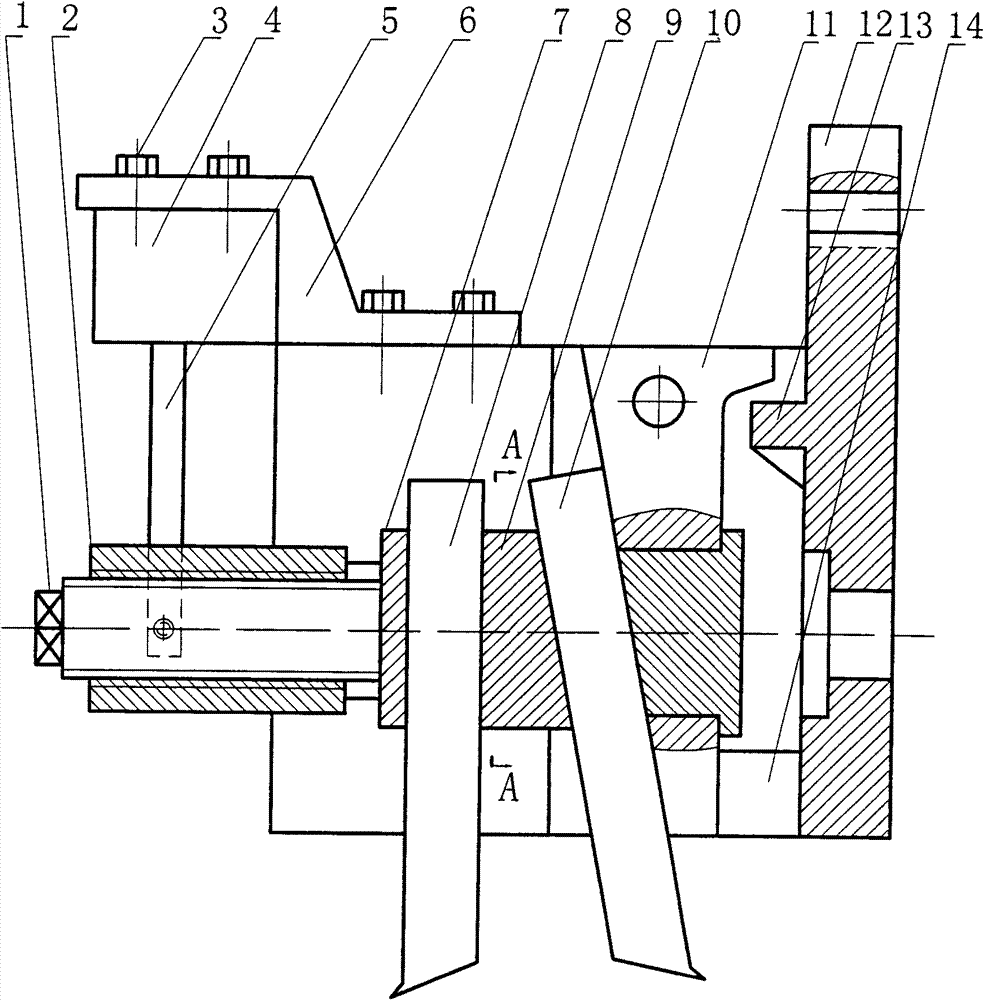

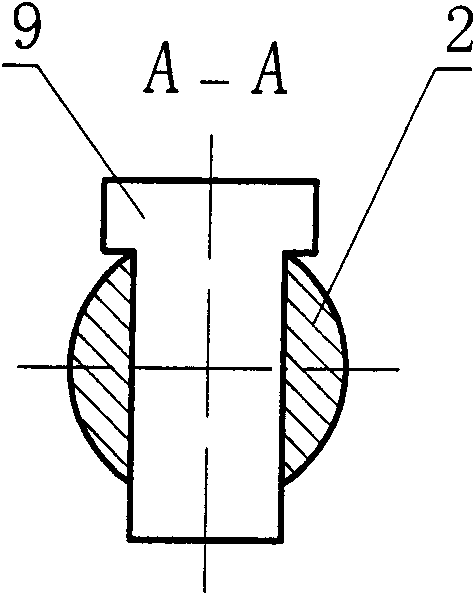

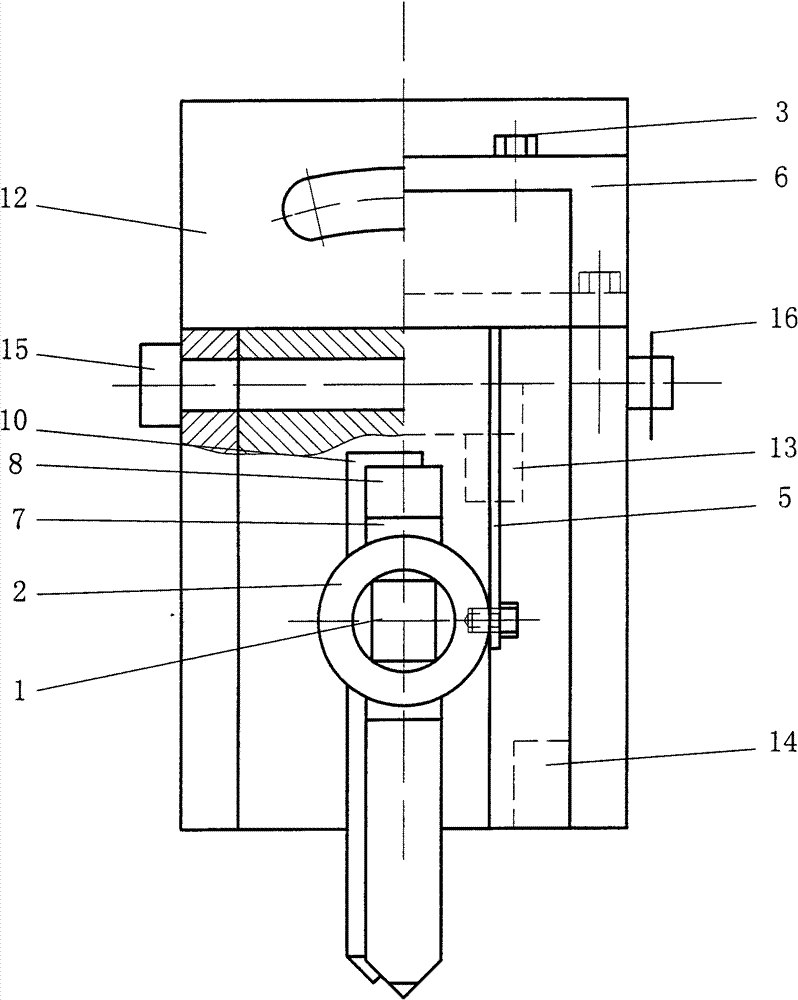

[0015] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, a two-way planer cutting mechanism, which includes a tool holder 11, a tool holder seat 12, a tool holder pressing shaft 2, a wedge-shaped pressing block 9, a screw 1, an electromagnet 4. The pin shaft 15, the rocker gear 17 and the control system are characterized in that: the tool holder pressing shaft 2 passes through the through hole of the tool holder 11 and is fixed as a whole by the screw 1, the square pressing block 7, and the wedge-shaped pressing block 9, Knife rest 11 links to each other with knife rest seat 12 by bearing pin 15, and the other end of pin shaft 15 links to each other with knife rest seat 12 by cotter pin 16, is provided with planer boss 13 at the upper end of knife rest seat 12 inner side, on the knife rest seat The lower end of the inner side of 12 is provided with a push planer boss 14, and a push planer 8 in a vertical state and a pull planer 10 inclined to the right at 5-10° are arranged on the too...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap