Anti-deformation assistive tool for welding thin-wall box bodies

A thin-walled box and anti-deformation technology, which is applied in welding/cutting auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of large welding deformation, high repair rate, and difficult control of box welding deformation. Small deformation, the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

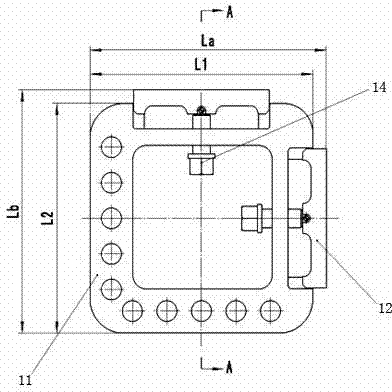

[0014] see Figure 4 , The anti-deformation aid is composed of two parts, the inner fixing frame 1 and the outer fixture 2.

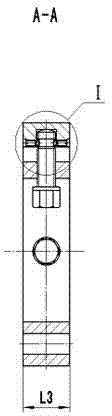

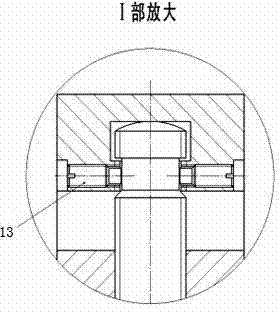

[0015] see figure 1 and figure 2 , The inner fixed frame 1 is used to support the base surfaces perpendicular to each other in the box, and it is composed of a square frame body 11, a movable briquetting block 12, an adjusting bolt 14 and a set screw 13. The length and width dimensions of the box body 11 are L1×L2. Connect a movable briquetting block 12 by adjusting bolts 14 on the upper and right two adjacent faces of the square frame body respectively, and by adjusting the adjusting bolt 14, the movable briquetting block 5 can be regulated so that the movable briquetting block can be adjusted relative to the position of the square frame body. The relative distance of the connection surface changes, that is, the dimensions La and Lb are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com