Fixture for linear cutting of oil scraper ring seats of piston rods of low-speed marine diesel engines

A technology of diesel engine and piston rod, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of small clamping space, time-consuming and labor-intensive operation of the workbench, and achieves wide applicability, convenient use, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

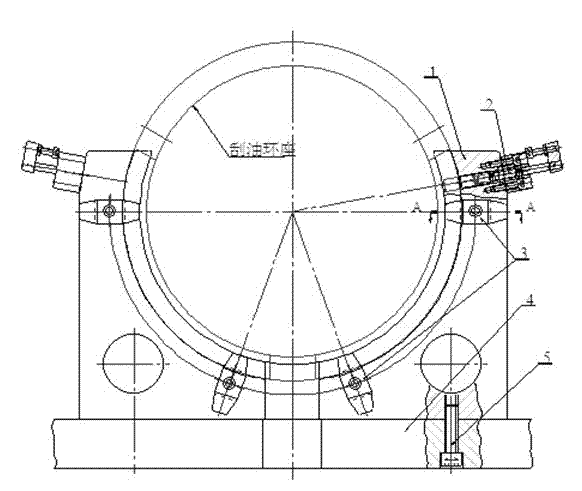

[0028] Please see first figure 1 , figure 1 It is a structural schematic diagram of the jig for wire-cutting the scraper ring seat of the piston rod of the marine low-speed diesel engine of the present invention. It can be seen from the figure that the clamp includes a clamp base 4, a clamp body 1 fixed on the clamp base 4 by two hexagon socket head cap screws 5, a positioning pin 2 and an elastic pressure plate 3 installed on the clamp body 1; There are annular grooves, grooves and spring grooves that can accommodate the scraper ring seat for wire cutting. The diameter of the annular groove is larger than the diameter of the oil scraper ring seat. There is also a pin hole on the clamp body 1 for fixing the positioning pin 2; Specifically, a plurality of through holes are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap