Large big-tolerance passive mildly-capturing space end effector based on tendon sheath drive

An end effector and large tolerance technology, which is applied in the docking device of aerospace vehicles, etc., can solve the problems of small capture tolerance and soft capture of the mechanical arm, and achieve soft capture, large space docking capture application prospects, large Effect of Tolerance Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

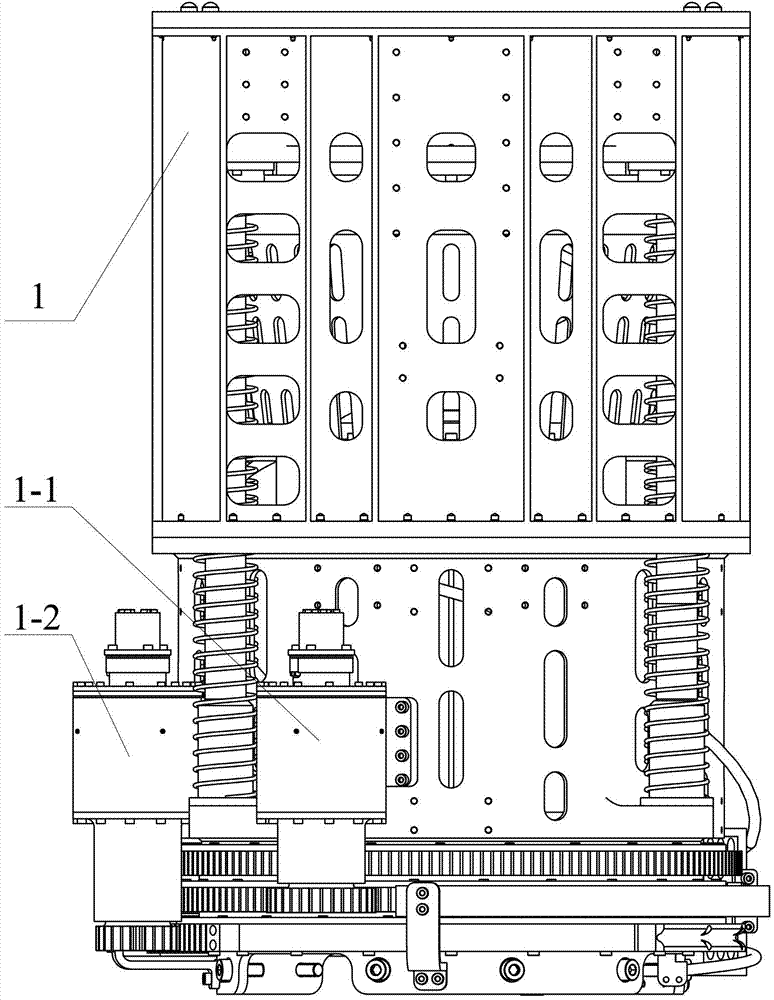

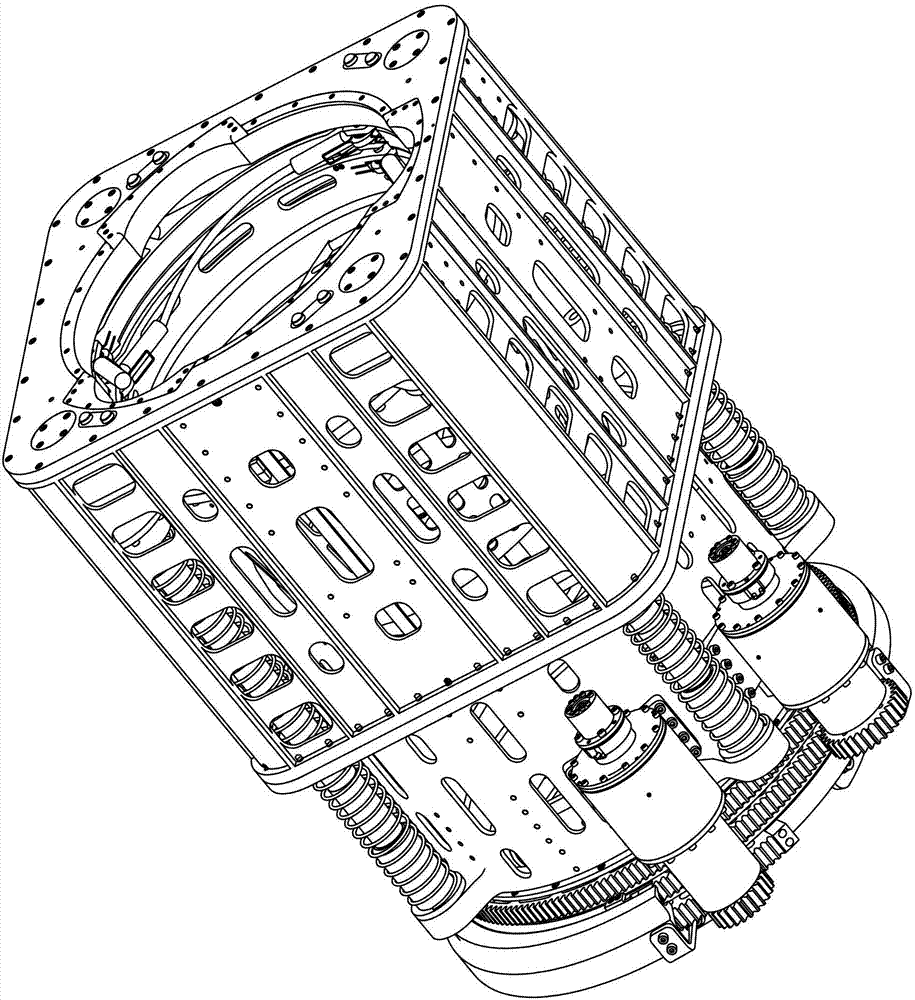

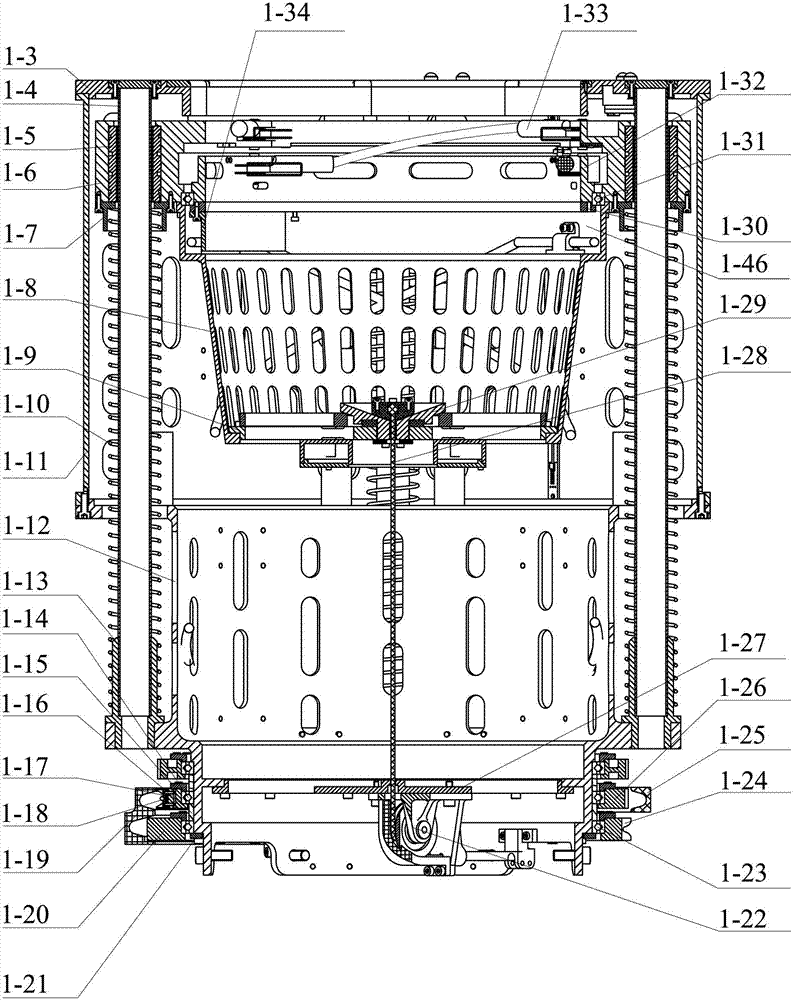

[0007] Specific implementation mode one: combine Figure 1 to Figure 15This embodiment is described. The large-scale and large-tolerance passive compliant capture end effector based on tendon sheath transmission described in this embodiment includes a capture device 1 and a capture interface device 2. The capture device 1 includes a support shell, a capture link, a drag link and a drag link. The dynamic link DC brushless motor drive system 1-2, the support shell includes the support shell upper part 1-11, the support shell lower part 1-12 and the end cover 1-3, the capture link includes the capture link DC brushless motor drive system 1-1, Four sliding bearing guide posts 1-4, four linear sliding bearings 1-5, capturing link fixed shell 1-6, four guide sleeves 1-7, supporting shell 1-8, drag link connecting ring 1- 9. Four compression springs 1-10, four-point contact thin-walled bearings 1-14 under the capture link, winding rollers 1-17 under the capture link, tendon 1-18 of t...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination image 3 , Figure 4 and Figure 5 Describe this embodiment. The dragging link of the large-scale, large-tolerance passive and compliant capture end effector based on tendon-sheath transmission in this embodiment includes a shaft sleeve 1-16, a dragging link gear 1-20, and an end cover 1-21. , drag link tendon guide wheel mechanism 1-22, drag link four-point angular contact bearing 1-23, drag link tendon winding roller 1-24, support plate 1-27, drag link tendon 1-28, drag link The end fixing device 1-29 of the moving link, the tendon protection sheath 1-39 of the drag link and the pre-tightening nut 1-40 of the drag link, the outer ring of the four-point angular contact bearing 1-23 of the drag link is fixed and set on the support by the end cover On the outer wall of the lower part of the lower part of the housing 1-12, the large gear 1-20 of the drag link is set on the four-point angular contact bearing 1-23 of the drag ...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 6 To illustrate this embodiment, the capture link DC brushless motor drive system 1-1 of the space-based large-scale large-tolerance passive compliant capture end effector based on tendon sheath transmission in this embodiment includes a capture link resolver 1-1-1, a capture link Electromagnetic power-down brake 1-1-2, capture link DC brushless motor 1-1-3, capture link harmonic reducer 1-1-4 and capture link pinion 1-1-5, capture link resolver 1-1-1 is connected to the power supply terminal of the capture link DC brushless motor 1-1-3 through the capture link electromagnetic power-down brake 1-1-2, and the output shaft of the capture link DC brushless motor 1-1-3 The capture link harmonic reducer 1-1-4 is connected with the capture link pinion gear 1-1-5, and the capture link pinion gear 1-1-5 meshes with the capture link large gear 1-26. Other components and connections are the same as those in the first embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com