Fast preparation method of ferrous microporous composite molecular sieves

A composite molecular sieve and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as backward solutions and products, products that fail to meet design requirements, and achieve accurate and accurate data and advanced technology. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

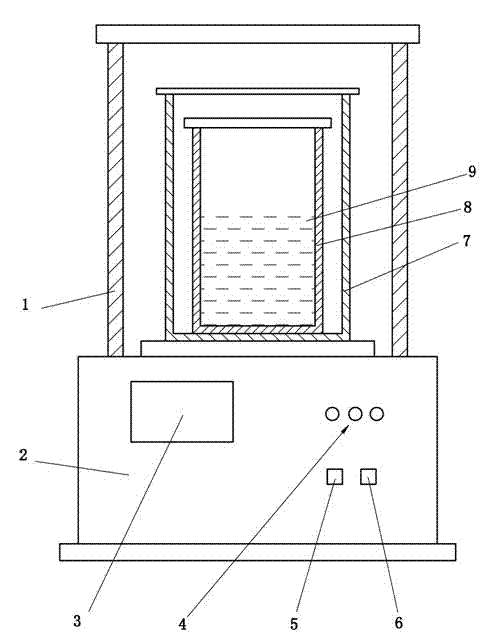

[0088] The preparation of single molecular sieve is carried out in the reactor, which is completed in the process of heating, sealing and static crystallization in the heating furnace;

[0089] The heating furnace 1 is rectangular, and the first reaction kettle 7 is placed in the heating furnace 1, and the polytetrafluoroethylene container 8 is placed in the first reaction kettle 7, and the polytetrafluoroethylene container 8 is a mixed reaction solution 9; For the console 2, a display screen 3, an indicator light 4, a power switch 5, and a temperature controller 6 are set on the console 2.

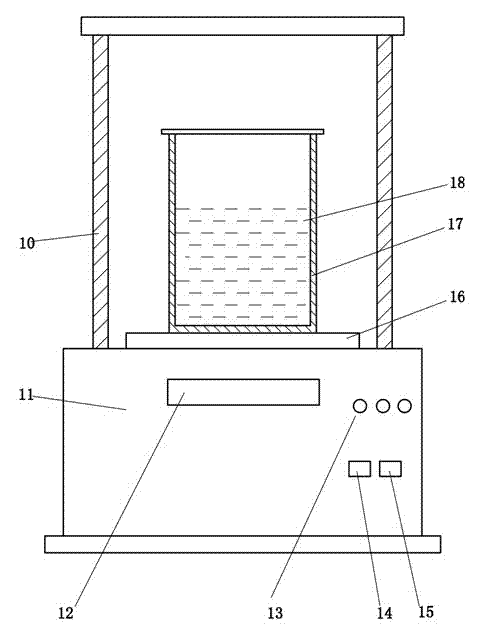

[0090] figure 2 As shown in the figure, it is a state diagram for the preparation of the iron-containing microporous composite molecular sieve mixture. The position of each part must be correct, the proportion should be proportioned, and the operations should be performed in sequence.

[0091] The preparation of the iron-containing microporous composite molecular sieve mixture is carrie...

Embodiment 1

[0098] The microporous composite molecular sieve can also be doped with cobalt nitrate during the preparation process to produce a cobalt-containing microporous composite molecular sieve, and its preparation method is the same as the above scheme.

Embodiment 2

[0100] The microporous composite molecular sieve can also be doped with nickel nitrate during the preparation process to make a nickel-containing microporous composite molecular sieve, and the preparation method is the same as the above scheme.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com