Granular sludge integrated autotrophic nitrogen removal device and operating method thereof

A technology of granular sludge and autotrophic denitrification, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of enriching anammox bacteria and reduce nitrate The effect of nitrogen generation, reduction of floor space, and increase of aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

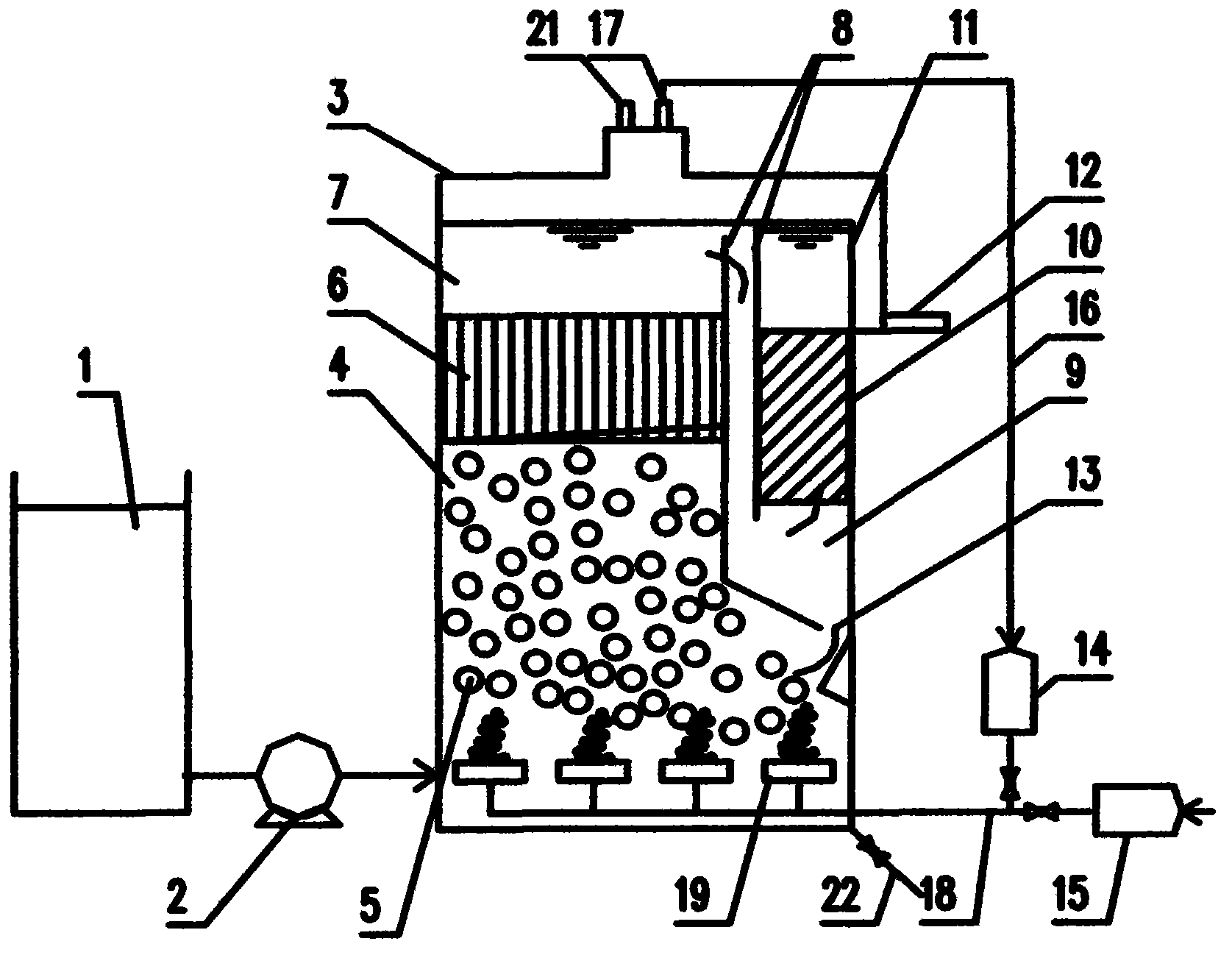

[0022] In conjunction with the accompanying drawings and examples, the patent application is further described: as figure 1 As shown, the granular sludge integrated autotrophic denitrification device of the present invention is composed of an inlet water tank 1 , an inlet pump 2 and an integrated anammox reactor 3 . The volume of the water inlet tank 1 is 400L, and the total volume of the integrated anammox reactor 3 is 20L, of which the effective volume is 15L. Air compressors are used for aeration and gas return.

[0023] The influent water used in the example is high ammonia nitrogen sludge dehydration liquid, which is taken from the sludge dehydration room of Beijing Gaobeidian Sewage Treatment Plant. The average concentration of ammonia nitrogen in the influent water is 410mg / L, and the COD is 200mg / L, which is stored in the influent water tank 1 before use.

[0024] Utilize the operation method step of above-mentioned device as follows:

[0025]1) Inoculation sludge: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com