Preparation method and application of fiber-reinforced thermoplastic composite material

A technology of fiber reinforcement and composite materials, applied in the field of composite materials, to achieve the effects of avoiding aging and rust, good aging resistance, and improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The embodiment of the present invention discloses a preparation method of a fiber-reinforced thermoplastic composite material, comprising the following steps:

[0023] impregnating the fiber in a melt including thermoplastic resin to obtain a prepreg tape;

[0024] The prepreg tape is braided to obtain a fiber-reinforced thermoplastic composite material.

[0025] According to the present invention, in the process of preparing the fiber-reinforced thermoplastic composite material, a prepreg tape is firstly prepared. The prepreg tape is a prepreg tape in which fibers are impregnated in resin. In order to bond well with the resin, the fibers are preferably surface-treated, so that the fibers are dispersed in the resin at the level of monofilaments, so as to bond well with the resin. The surface treatment agent for the fiber surface treatment preferably includes but not limited to one or more of silanes, titanates, aluminates, organic chromium complexes, phosphoric acid e...

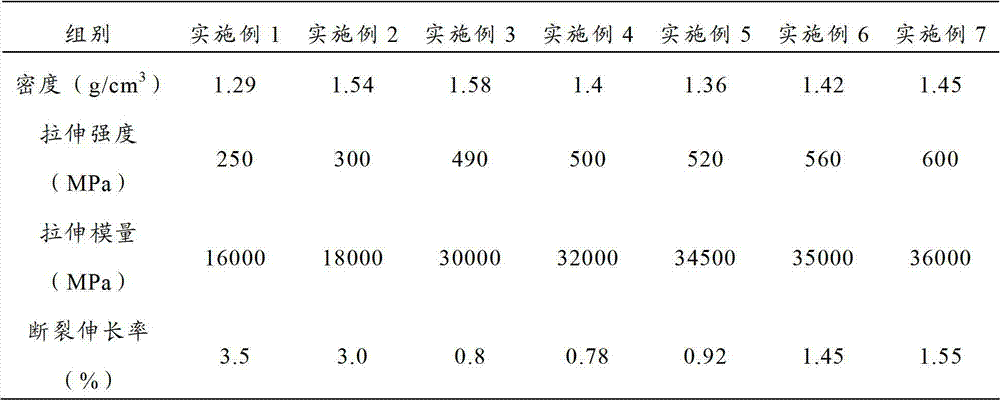

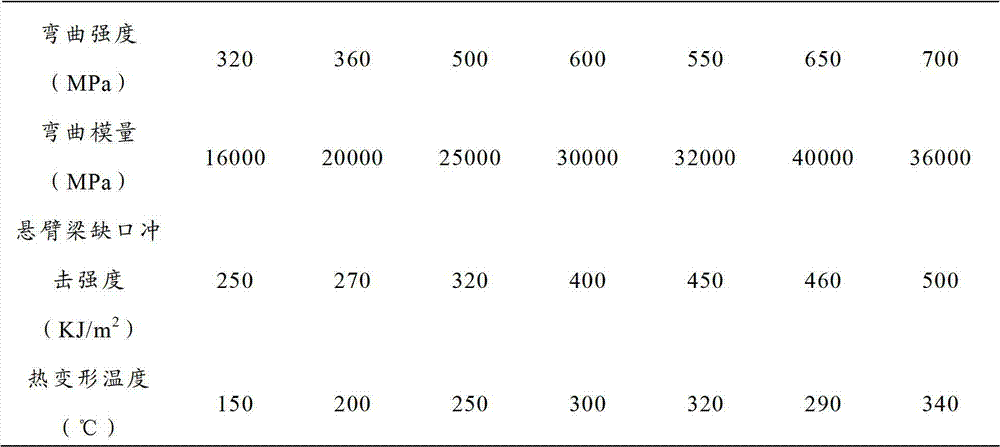

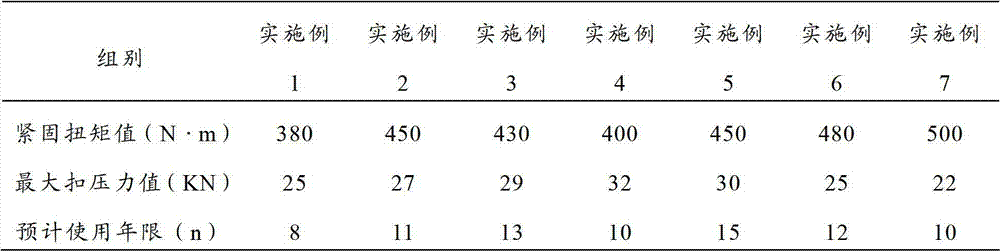

Embodiment 1

[0039] After 45wt% of the glass fiber is treated with a titanate surface treatment agent, it enters a preheating oven at 140°C for preheating, and at the same time, 55wt% of the polypropylene resin is plasticized in the extruder, and the heating temperature of the extruder is At 180°C, the polypropylene resin is plasticized and extruded to the die through the extruder. The preheated glass fiber enters the die with a fiber dispersion device. The temperature of the die is 230°C. In the die, the glass fiber is Dispersed and fully impregnated with polypropylene resin; after the fully impregnated glass fiber leaves the die, it is rolled into a pre-impregnated tape by the pressing roller group. Under the traction of the traction motor, the pre-impregnated tape enters the braiding machine at 0° and 90° Orthogonal weaving is carried out in the direction, and a sheet material with a two-dimensional or three-dimensional orientation structure is woven to obtain a fiber-reinforced thermopl...

Embodiment 2

[0041] After 50wt% of the glass fiber is treated with an aluminate surface treatment agent, it enters a preheating oven at 160°C for preheating, and at the same time, 50wt% of the nylon 6 resin is plasticized in the extruder, and the heating temperature of the extruder is 200°C, Nylon 6 resin is plasticized and extruded to the die through the extruder. The preheated glass fiber enters the die with a fiber dispersion device. The temperature of the die is 260°C. In the die, the glass fiber is Dispersed and fully impregnated with nylon 6 resin; after the fully impregnated glass fiber leaves the die, it is rolled into a pre-impregnated tape by a roller group, and under the traction of the traction motor, the pre-impregnated tape enters the weaving machine for weaving, and is woven into two A sheet with a one-dimensional or three-dimensional orientation structure is obtained to obtain a fiber-reinforced thermoplastic composite material, and the traction speed of the traction motor i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Torque value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com