On-line pipeline deaeration device and deaeration process

A line-type, pipeline technology, applied in spinning solution degassing, spinning solution filtration, fiber treatment, etc., can solve problems such as inability to realize online continuous spinning operation, adverse effects on physical and chemical properties, unsatisfactory degassing effect, etc. , to achieve the effect of low cost, guaranteed quality and high defoaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

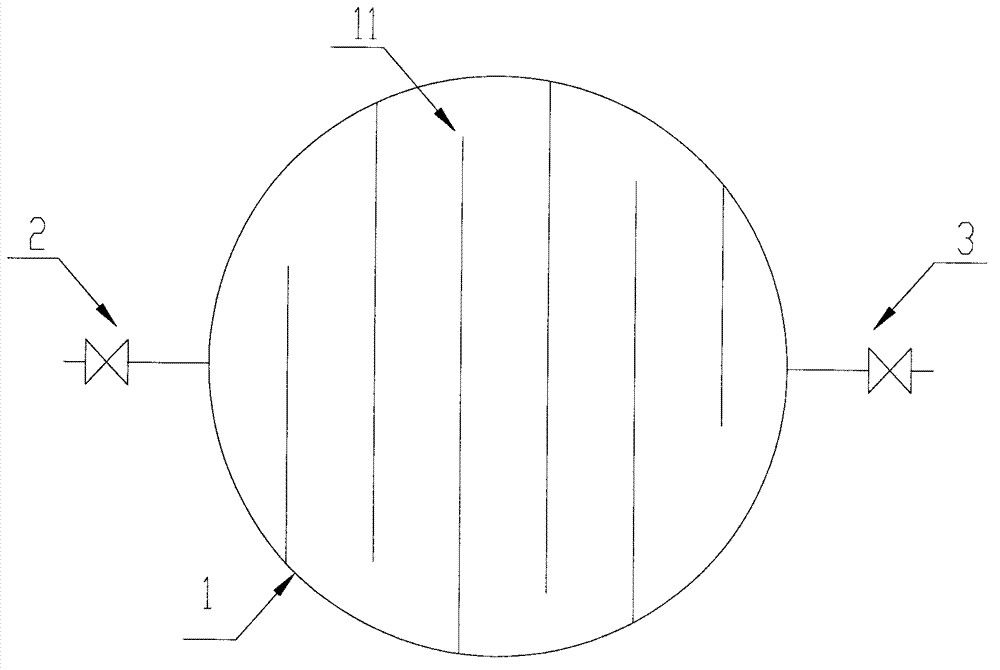

[0020] A pipeline on-line degassing device, as attached figure 1 As shown, it includes a material tank 1 , a feed valve 2 , and a discharge valve 3 . The outer surface of the bottom of the material tank 1 is provided with an ultrasonic transducer group 4 , and the ultrasonic transducer group 4 is connected to an ultrasonic generator 5 . The top of the material tank 1 is provided with a vent valve 6, the spinning solution entering the material tank 1 from the feed valve 2 forms the lower feed liquid layer 7, and the gas entering the material tank 1 from the vent valve 6 forms the upper gas layer 8. The top of the material tank 1 is provided with a window 9 and a pressure gauge 12, and the window 9 is used to observe the height of the material liquid layer 7 below. The side wall and the bottom wall of the material tank 1 are of double-layer structure, and the interlayer 10 formed by the double-layer structure is passed into a temperature-controlling liquid. as attached figure...

Embodiment 2

[0024] Using the same device and method as in Example 1, the temperature-controlling liquid is heat-conducting oil, and the ultrasonic transducer groups 4 are 2 groups, and each ultrasonic transducer group 4 includes 4 ultrasonic transducers, so The ultrasonic frequency of the ultrasonic generator 5 is 40K, the ultrasonic power is 100W, and it is used for the spinning solution with a viscosity of 10000cP.

[0025] The polyethersulfone hollow fiber membrane is prepared by a wet method using the above-mentioned defoaming device: turn on the oil heating, and set the temperature of the material tank 1 to the required temperature of 90 degrees Celsius for spinning. Connect the ventilation valve to the normal pressure atmosphere, open the ventilation valve 6, turn on the ultrasonic generator 5, use a group of ultrasonic transducer group 4, open the feed valve 2, and observe the height of the feed liquid in the material tank 1 from the window 9, Until the liquid level reaches the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com