Swing type bidirectional positioning clutch

A two-way positioning and clutch technology, applied in the field of clutches, achieves the effects of good product consistency, simple structure, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

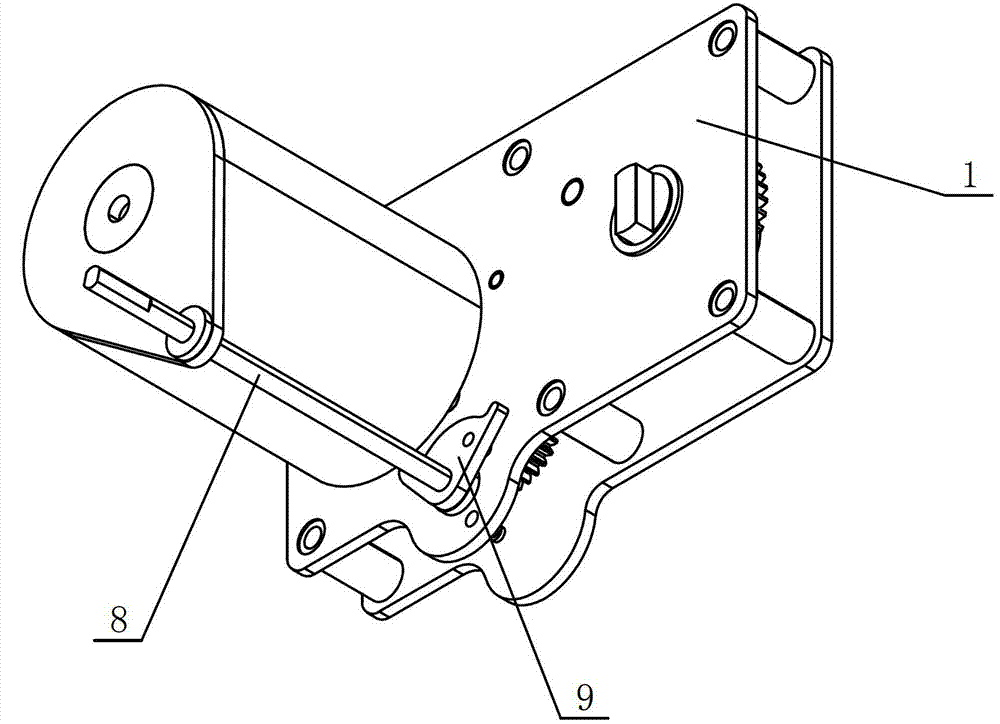

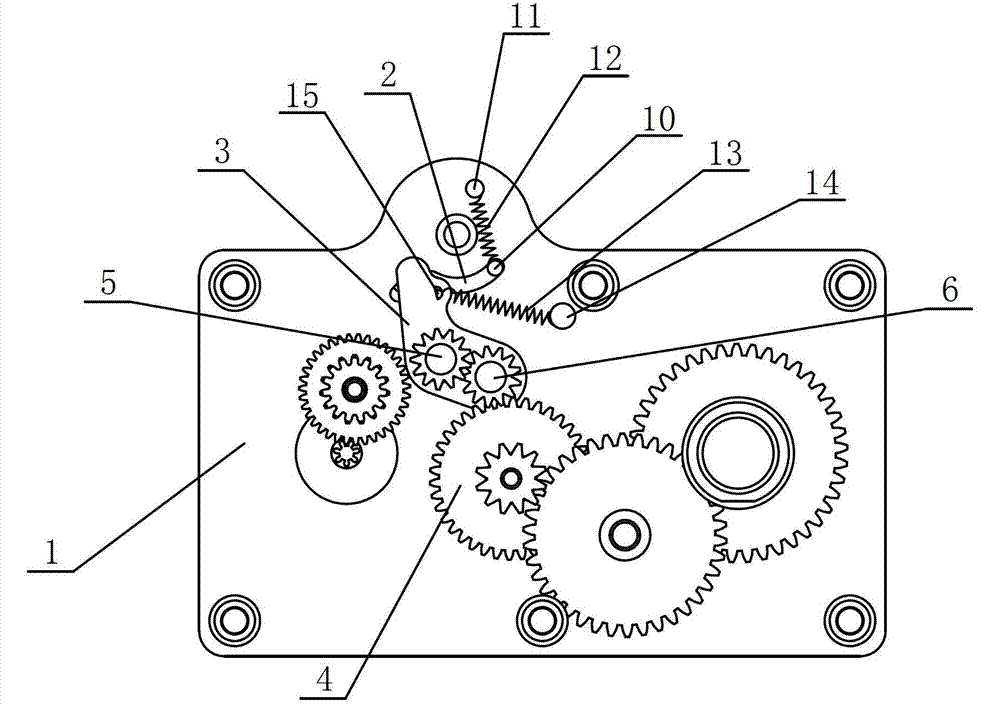

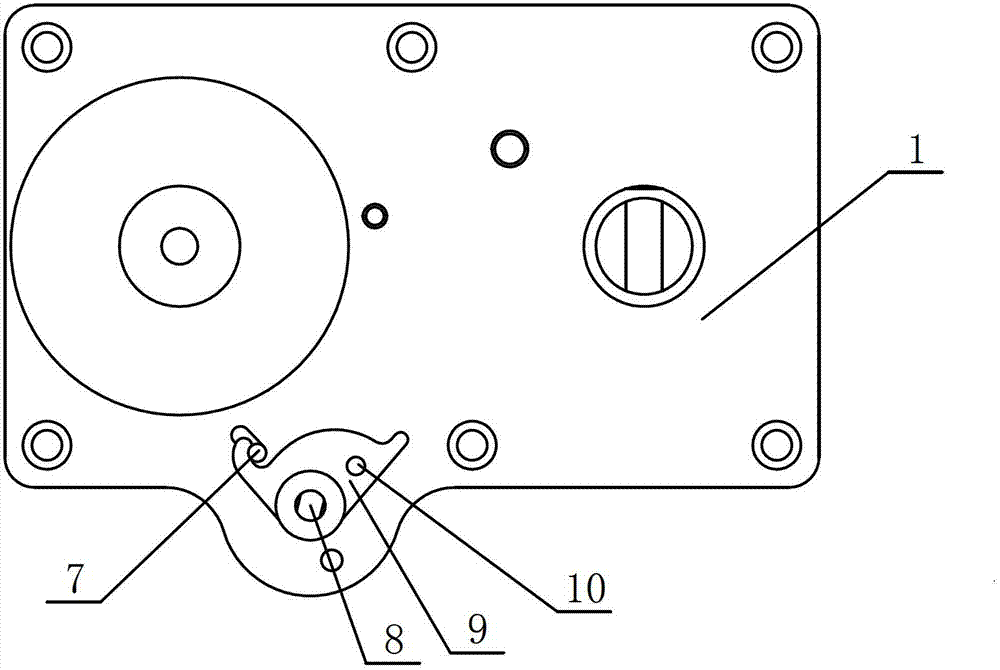

[0017] see Figure 1 to Figure 3 As shown, in this embodiment, a swing type two-way positioning clutch includes a box body 1 and a reduction gear assembly assembled on the box body 1, and a section of arc-shaped chute 2 is opened on the side wall of the box body 1 , and the inner side of the box body 1 is rotatably installed with a rocking plate 3, and a driving gear 5 and a swing gear 6 which mesh with each other are installed on one side of the rocking plate 3, and the swing gear 6 can be optionally combined with a reduction gear assembly The driven gear 4 is disengaged or meshed. The other side of the rocking plate 3 is fixedly connected with the locking pin 7, and the outer side of the box body 1 is rotatably provided with a rocker 8, and the two-way limit cams with card slots at both ends are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com