Temperature controllable type lithium ion battery module for vehicles

A lithium-ion battery, lithium battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of rising to 45 to 50 degrees Celsius, sometimes even 55 degrees Celsius, battery damage, damage or failure, etc. The effect of life and use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

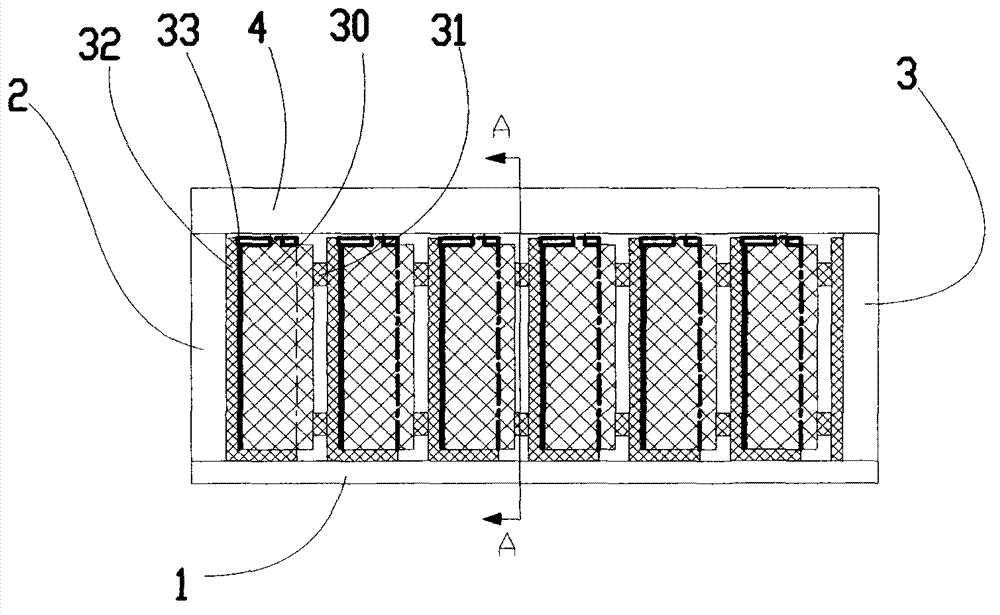

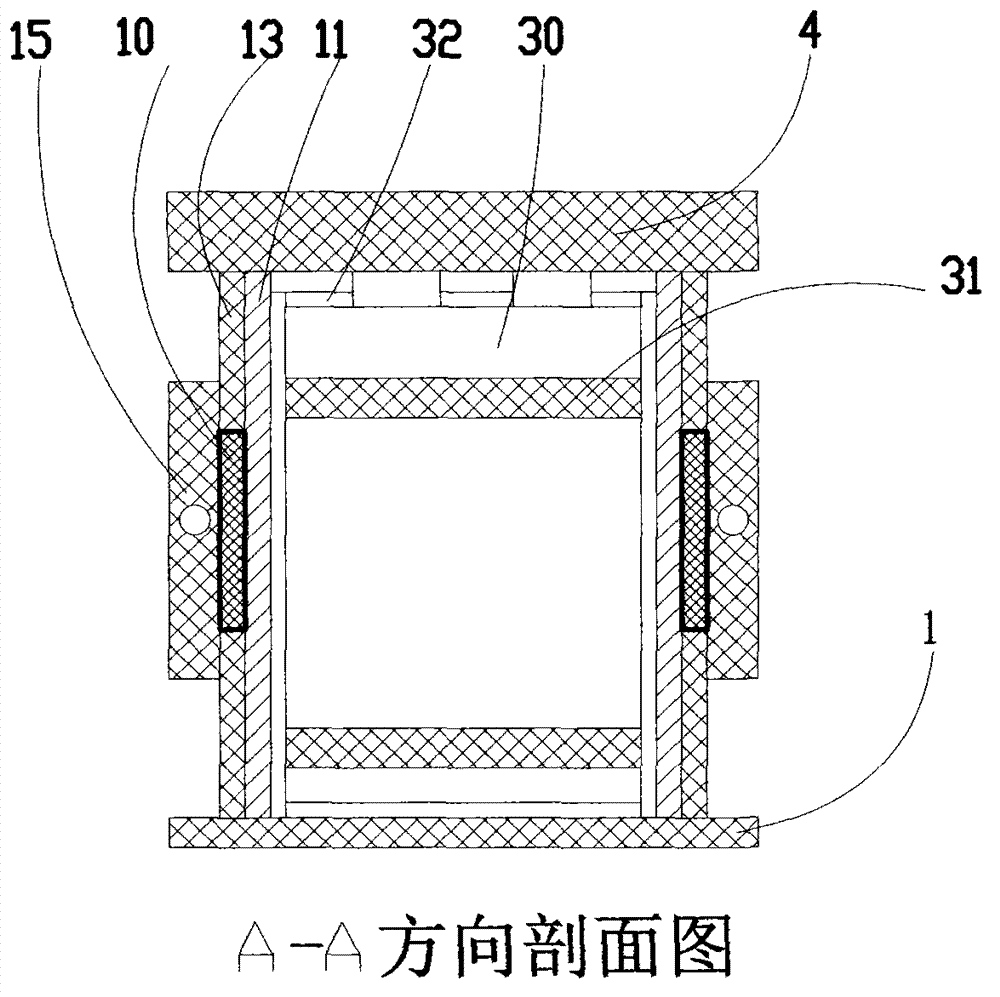

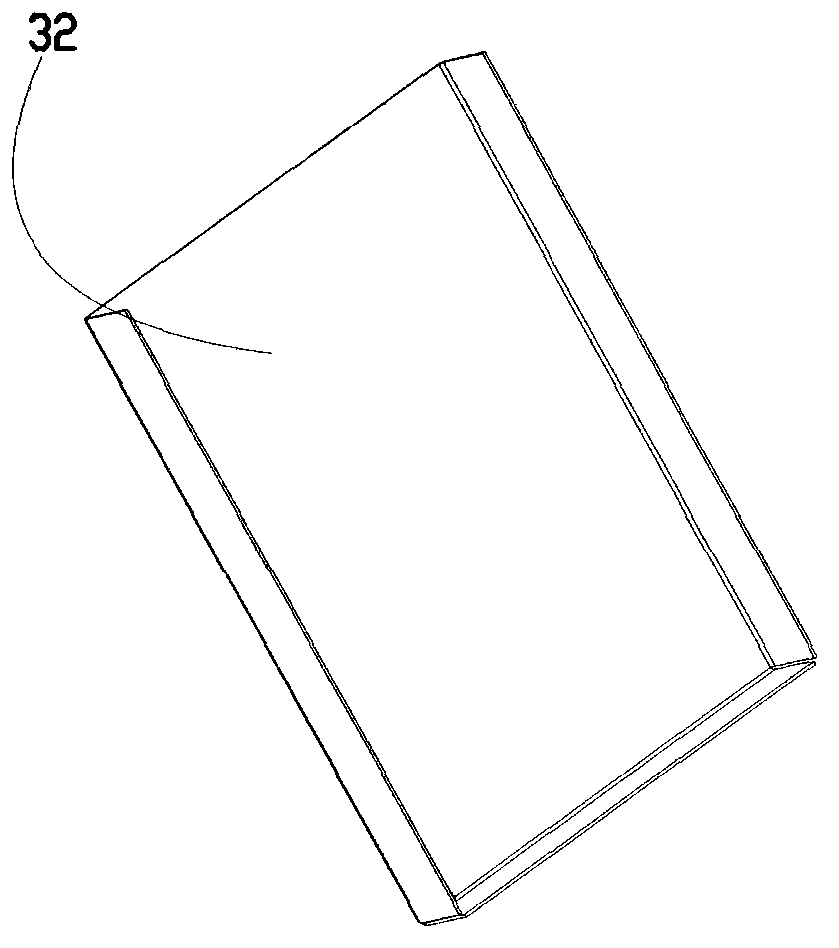

[0014] From figure 1 It can be seen that the temperature-controlled vehicle lithium-ion battery module housing part of the present invention is composed of a bottom plate 1, side baffles 2 and 3, and an upper cover 4. A plurality of lithium battery cores 30 are housed in the housing, and each lithium battery One side of the core 30 is connected with a compressible rubber strip 31, and the other side of the lithium battery core is seated in a dustpan-shaped aluminum box 32 folded at 90 degrees on three sides, and a viscous heat-conducting silicone grease layer passes through the three sides. 33 is seamlessly bonded with the aluminum box 32, and the outside of the aluminum box 32 on the middle battery core is connected with the adhesive strip 31 fixed on the adjacent battery core 30.

[0015] From figure 2 , image 3 , Figure 4 It can be seen that the refrigerating part of the present invention is composed of interconnected semiconducting refrigerating sheets 10 and heat-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com