Constant voltage oil sealing method for thermal shrinkage cable head

A cable head, heat shrinking technology, applied in the direction of air-filled/oil-filled cable accessories, etc., to eliminate oil leakage, improve safety factor, and increase pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

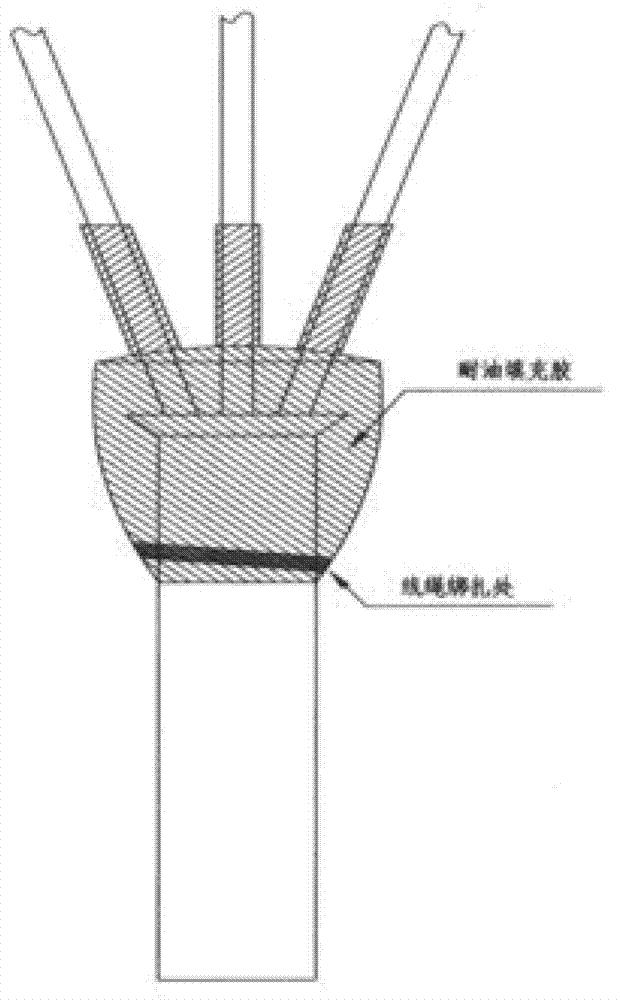

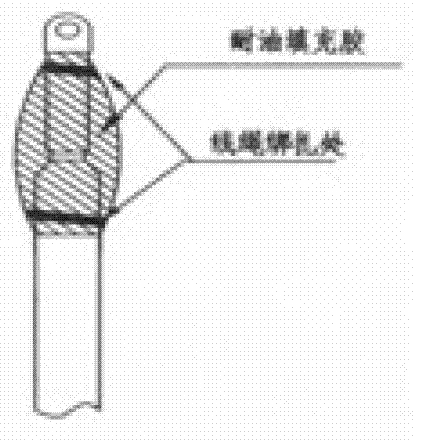

[0011] Such as figure 1 , figure 2 with image 3 As shown, the following is a detailed description of the heat shrinkable manufacturing process of the oil-impregnated paper cable end:

[0012] Step 1: Strip the outer sheath and weld the ground wire: fix the cable vertically, measure 760mm from the end, then peel off the outer sheath of the quilt, measure up the 50mm steel armor, lashing wire, and the rest from the fracture of the outer sheath Strip off the steel armor, tear off the inner protective layer layer by layer (if necessary, use a blowtorch to evenly bake), clean the surface of the lead bag about 200mm upwards from the armour fracture, and then roughen the surface of the lead bag by 120~200mm from the armour fracture. Weld the ground wire to the armored place (according to the welding standard), keep the 120mm lead package upward from the armo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com