Super hard material synthetic press integrated valve plate type hydraulic station

A technology that integrates valve plates and superhard materials, applied in the application of ultra-high pressure processes, etc., can solve the problems of easy clogging of filter elements, many oil leakage points, complex oil circuits, etc., to improve sealing reliability, prolong service life, Guaranteed normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

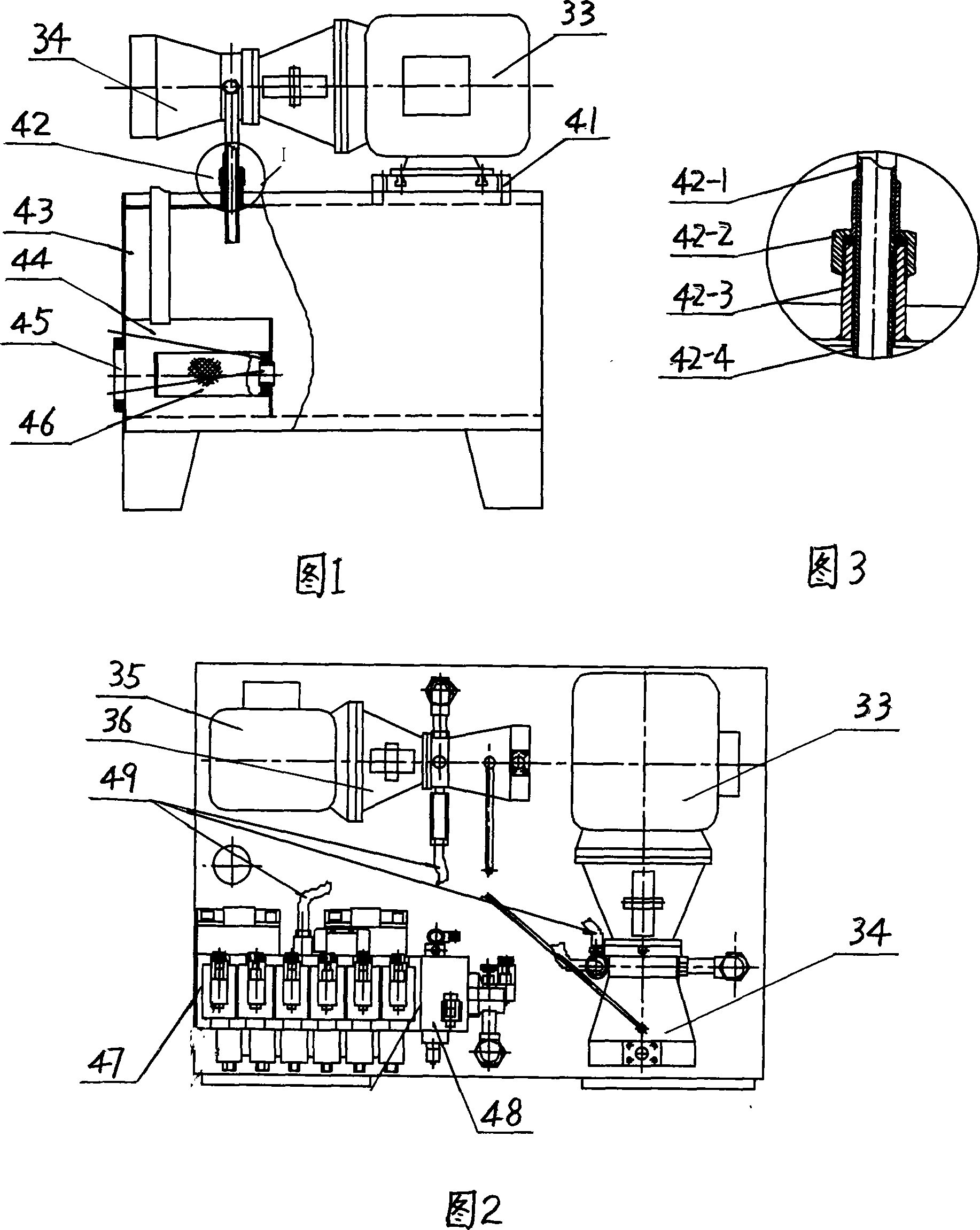

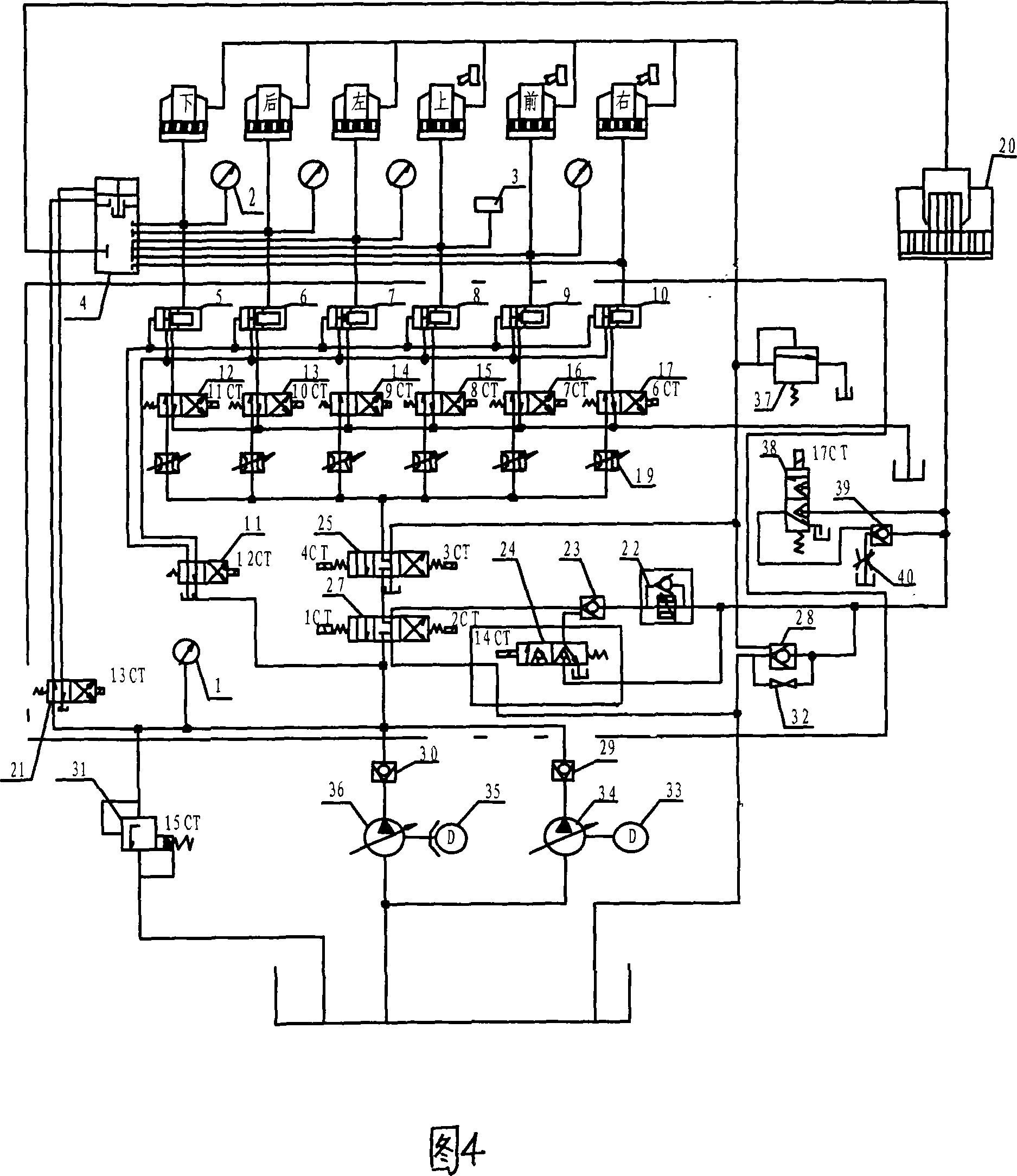

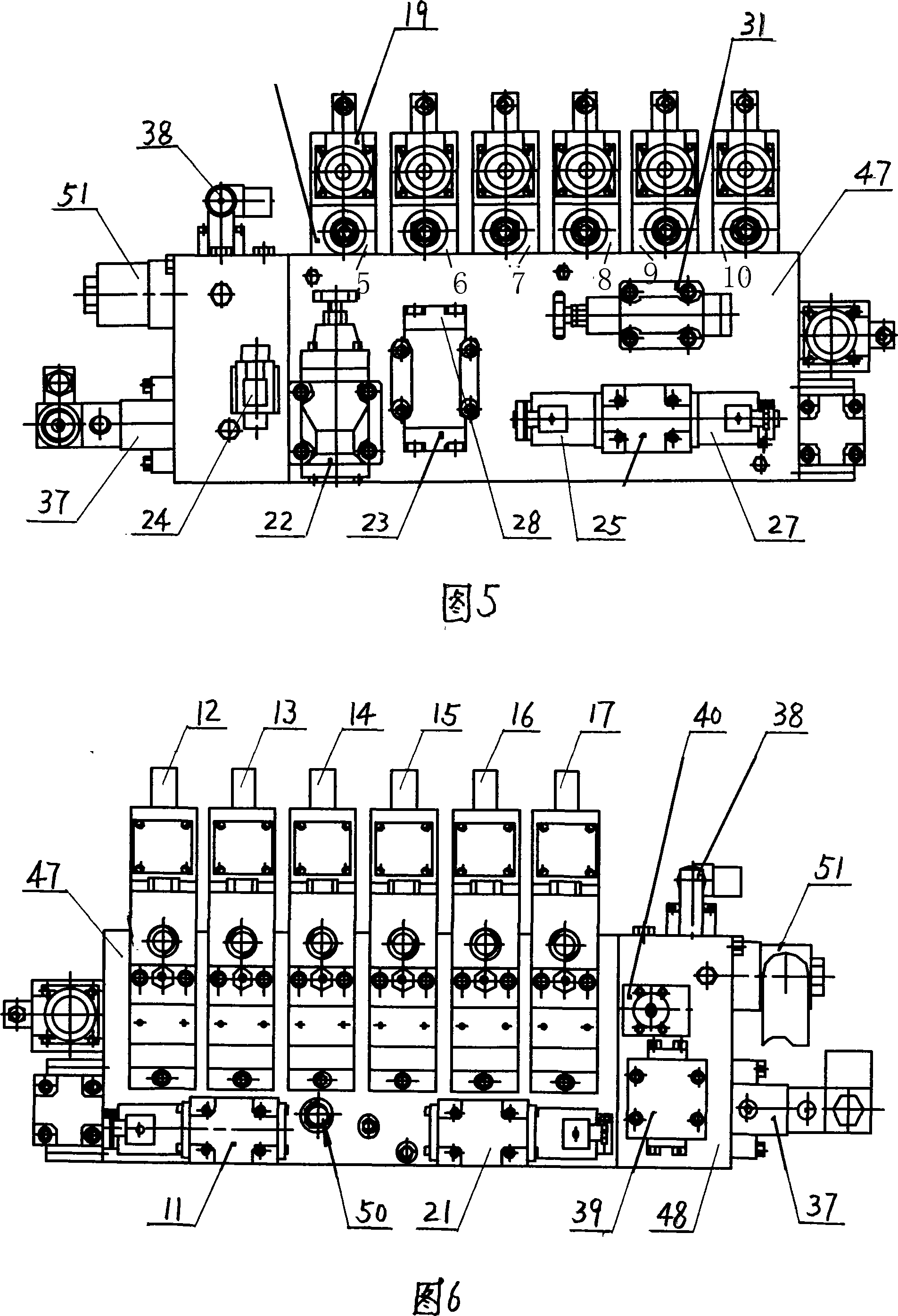

[0031] Referring to Figure 1, Figure 2, Figure 3, the hydraulic station of the present invention is composed of motors 33, 35, oil pumps 34, 36, an oil tank and a hydraulic control system. Among them, the oil pumps 34 and 36 are fixedly connected to the motors 33 and 35 respectively, and are driven by the motors to run. The motors 33 and 35 are installed on the top cover of the fuel tank through their respective backing plates 41. The backing plate 41 is provided with a cross chute. The installation positions of the motors 33 and 35 can be adjusted in both directions through the cross chute. There are dimensions in the relevant components. It can be installed easily and quickly even in the case of error or deformation.

[0032] In order to facilitate installation, ensure sealing and prevent leakage, an easy-to-disassemble oil pipe assembly 42 is installed between the oil pumps 34 and 36 and the oil tank. The oil pipe assembly consists of an oil suction pipe 42-1 connected to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com