Energy consumption reduction hydraulic pump device

A technology for reducing energy consumption of hydraulic pumps, which is applied in the field of new high-efficiency hydraulic pump devices, can solve the problems of wasting energy consumption of circulating water, and achieve the effects of saving electric energy, maintaining sanitation and cleanliness, and eradicating oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

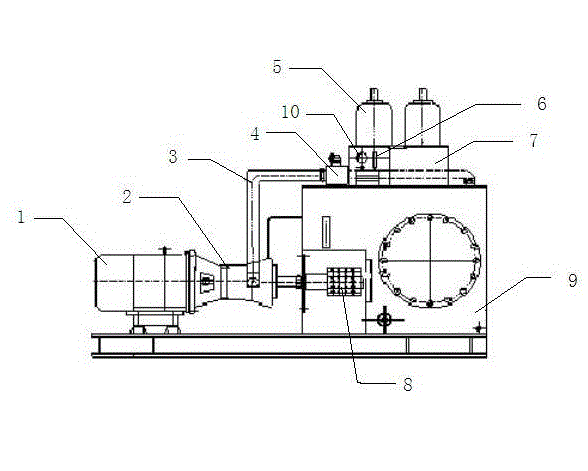

[0010] Such as figure 1 As shown, a hydraulic pump device for reducing energy consumption is composed of a motor 1, a high-pressure oil pipe 3, an electromagnetic overflow valve 4, an accumulator 5, a pressure transmitter 6, a PLC program control cabinet 7, and an oil tank 9. The motor 1 The end is provided with a plunger pump 2 and a current-free frequency converter 8, and the high-pressure oil pipe 3 is connected with the plunger pump 2 and the electromagnetic overflow valve 4, and one end of the electromagnetic overflow valve 4 is provided with a pressure transmitter 6, and the pressure transmitter A pressure gauge 10 is provided at the front end of the transmitter 6 . The PLC program control cabinet 7 and the non-current frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com