Heat-dissipating tape and method for manufacturing same

A production method and tape technology, applied in chemical instruments and methods, adhesives, and other household appliances, can solve problems such as shortened service life and defective products, and achieve effective heat dissipation, excellent thermal conductivity, and excellent heat dissipation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

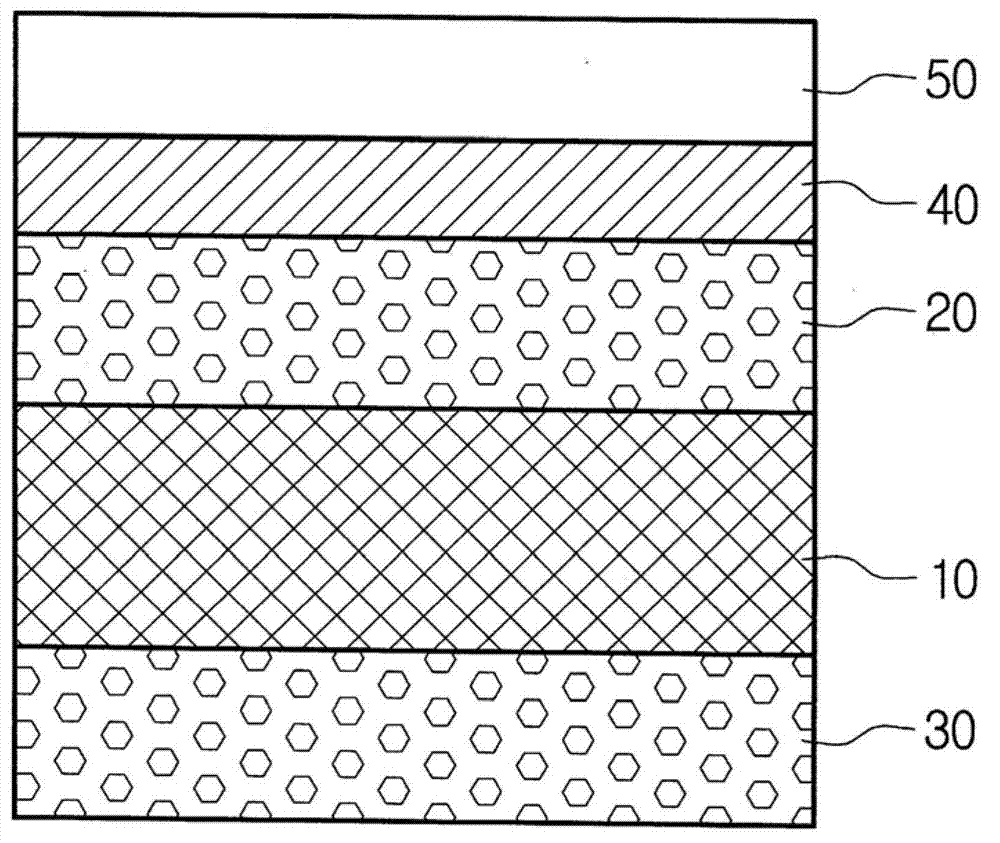

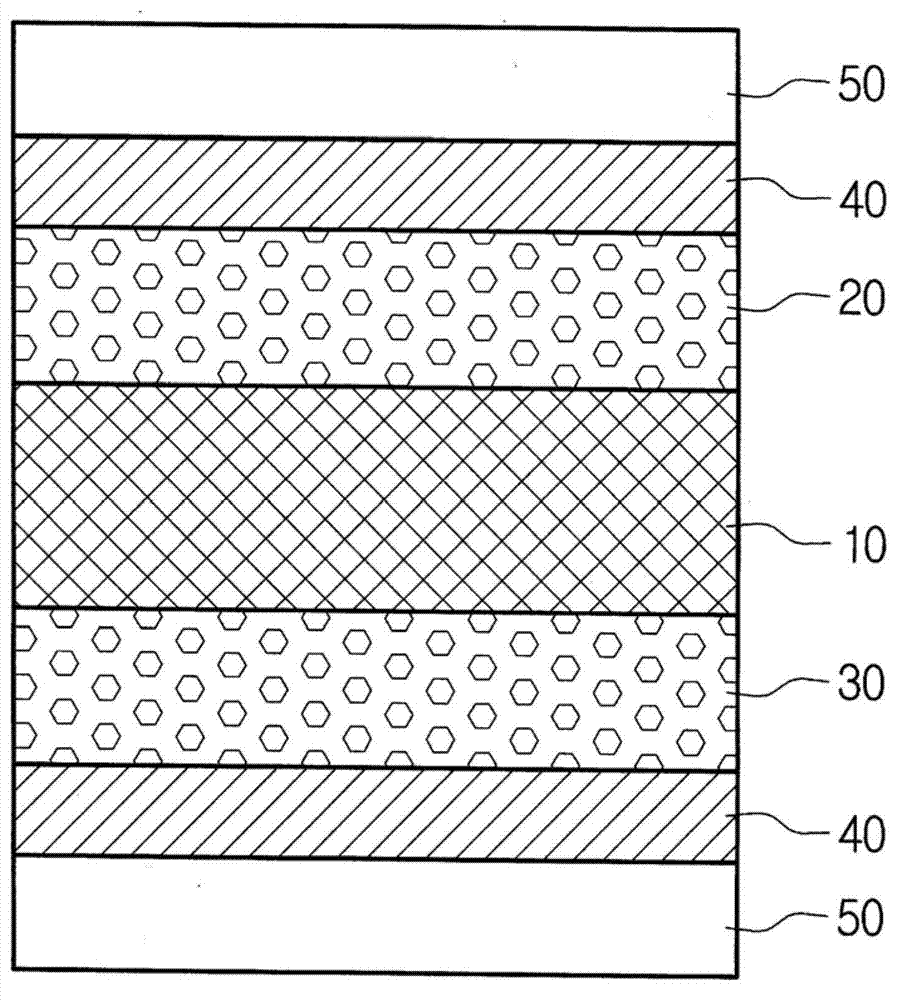

Method used

Image

Examples

Embodiment 1

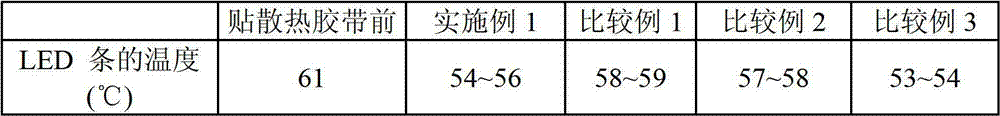

[0054] The heat dissipation tape in Example 1 showed a heat dissipation effect of reducing the temperature of the LED strip by 5-7°C. In Comparative Example 1, the temperature of the LED strip was reduced by 2-3°C, and in Comparative Example 2 by 3-4°C. At this time, since the thermal conductivity of the PET substrate and the adhesive is low, the heat dissipation effect will be reduced. Although comparative example 3 has the effect of lowering the temperature by 7~8°C, at this time, because the coating is easy to fall off or the adhesion is not good, the heat dissipation effect cannot be sustained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com