Anti-condensation steel silo for grain storage

A steel silo and anti-condensation technology, applied in the field of steel silo for storing grain, can solve the problems of not being able to be placed in a place with high light intensity, high drying requirements, and high humidity, so as to maintain the storage state and increase the overall The effect of circulation and temperature equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

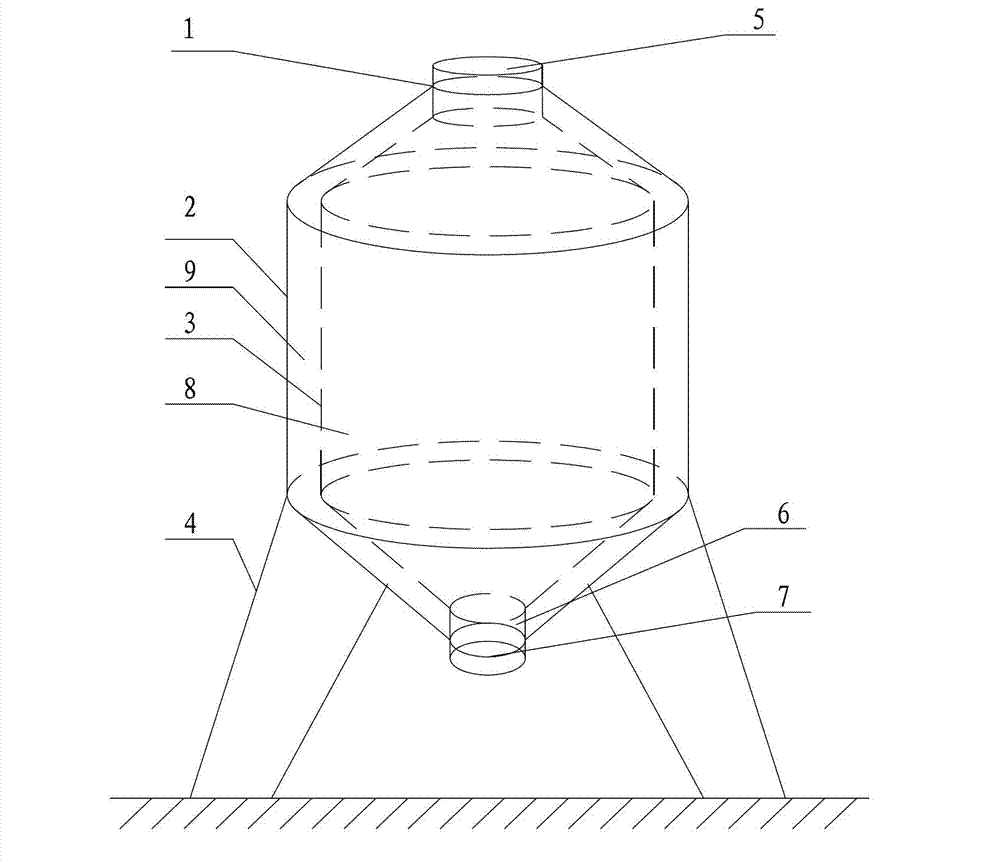

[0009] Such as figure 1 As shown, the anti-condensation storage grain steel silo mainly includes a steel silo body 2 and a bracket 4 .

[0010] The upper top of the steel bin body 2 is provided with a bin top port 1, and the bottom end is provided with a discharge port 6, the top port 1 is provided with a bin end cover 5, and the discharge port 6 is provided with a discharge port cover 7.

[0011] The steel plate bin body 2 is a hollow rotary structure made of steel plates.

[0012] The steel silo body 2 is fixed with an inner isolation layer 3 which is surrounded by a liner net and also has a hollow rotary structure. The mesh of the lining net is based on the standard that no wheat grains can leak out. The area enclosed by the inner isolation layer 3 is the grain storage area 8 , and the area between the inner isolation layer 3 and the inner wall of the steel bin body 2 is the air area 9 .

[0013] During use, the bin end cover 5 is opened, and the wheat grain is imported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com