Novel shirt and producing method thereof

A shirt, a new type of technology, applied to clothing, cuffs, fasteners, etc., can solve the problems of long production time, inconvenient disassembly, and high production costs, and achieve the effects of simple structure, reduced material costs, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

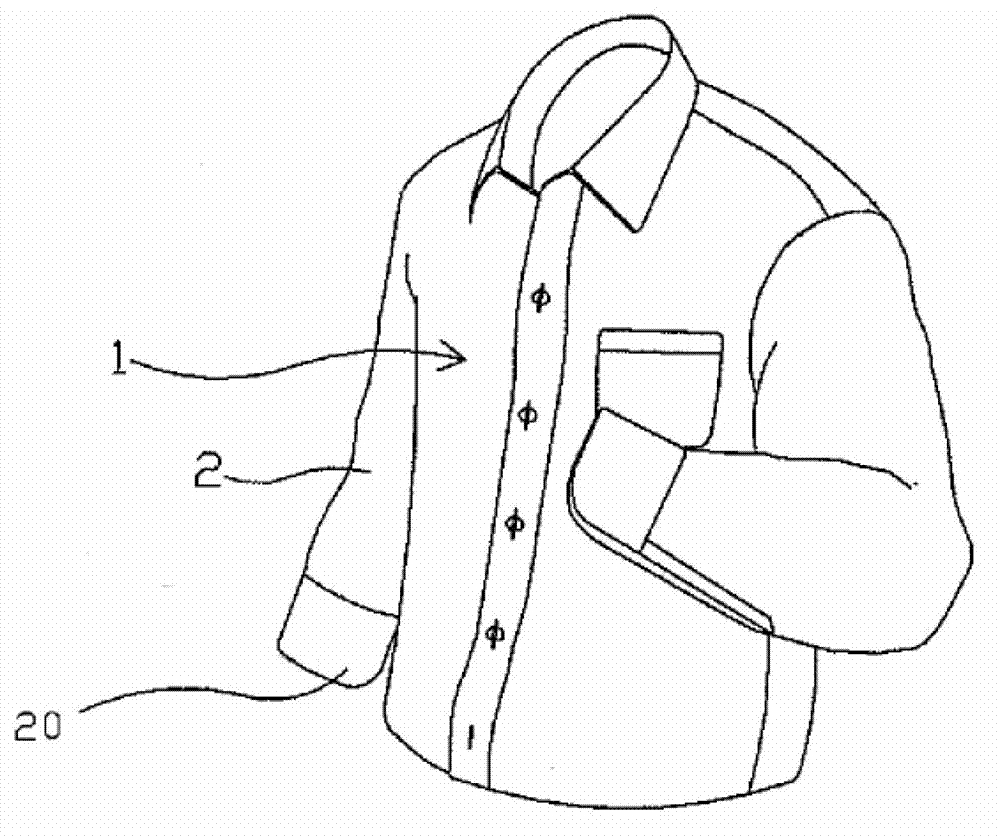

[0051] A new type of shirt, including a shirt main body 1, a sleeve main body 2, cuffs 20, elastic parts, and a cover 25;

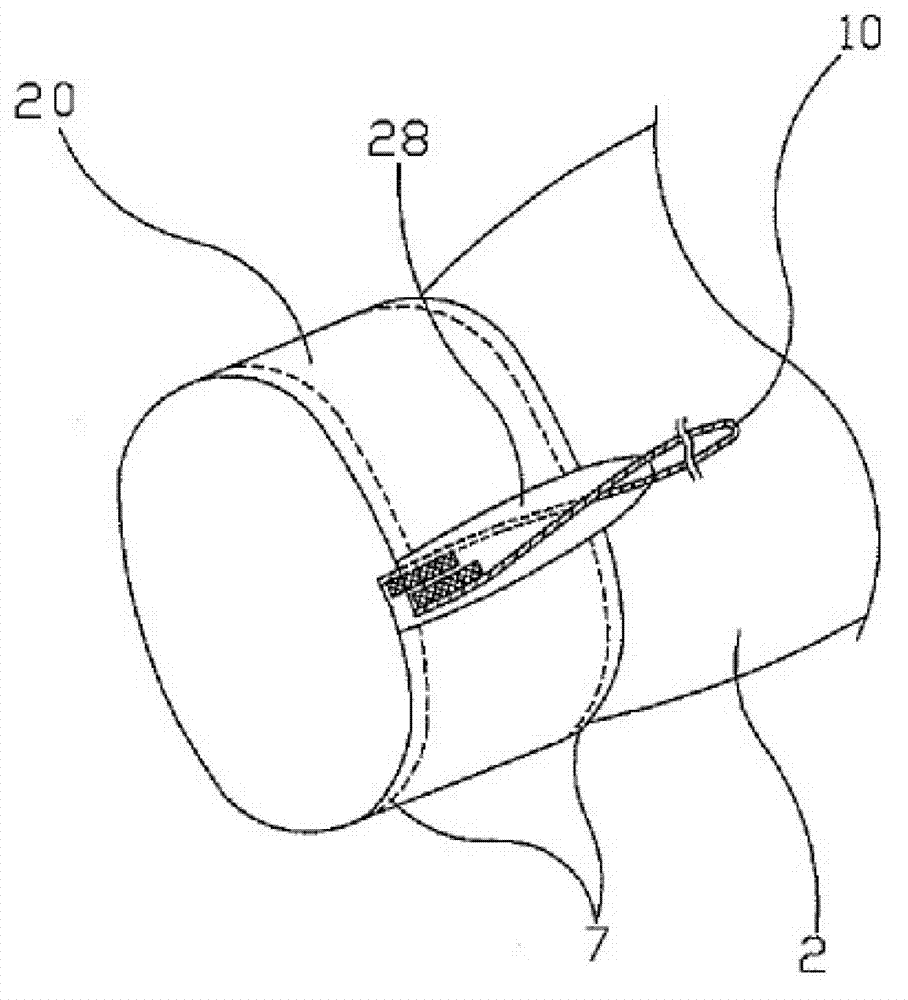

[0052] The sleeve 20 is sequentially composed of an outer lining 21, a fabric core 24, and an inner lining 22, and the outer lining 21 is fixedly connected with the fabric core 24; an insertion groove 27 is formed between the fabric core 24 and the inner lining 22;

[0053] The sleeve 20 is in the shape of 'C', and the sleeve end 15 is provided with an opening along the extension direction of the sleeve body 2. The sleeve end 15 at the front end of the sleeve body 2 is fixedly connected with the sleeve 20 by a suture 7, and the sleeve end The edge of the 15 opening is on the same horizontal line as the 'C' shaped edge of the cuff 20, and through insertion holes 28 are respectively arranged on both sides.

[0054] Preferably, the elastic component is a cuff 23 .

[0055] Preferably, the cuff 23 is 'C' shaped, inserted into the insertion groove 27, one sid...

Embodiment 2

[0073] A new type of shirt, including a shirt main body 1, a sleeve main body 2, cuffs 20, elastic parts, and a cover 25;

[0074] The cuff 20 is composed of an outer lining 21, a fabric core 24, and an inner lining 22 in turn, and the outer lining 21 is fixedly connected with the fabric core 24; an insertion groove 27 is formed between the fabric core 24 and the inner lining 22;

[0075] The cuff 20 is in a 'C' shape, and the sleeve end 15 is provided with an opening along the extension direction of the sleeve body 2. The sleeve end 15 at the front end of the sleeve body 2 is fixedly connected to the cuff 20 by a suture 7, and the sleeve end The edge of the 15 opening is on the same horizontal line as the 'C' shaped edge of the cuff 20, and through insertion holes 28 are respectively arranged on both sides.

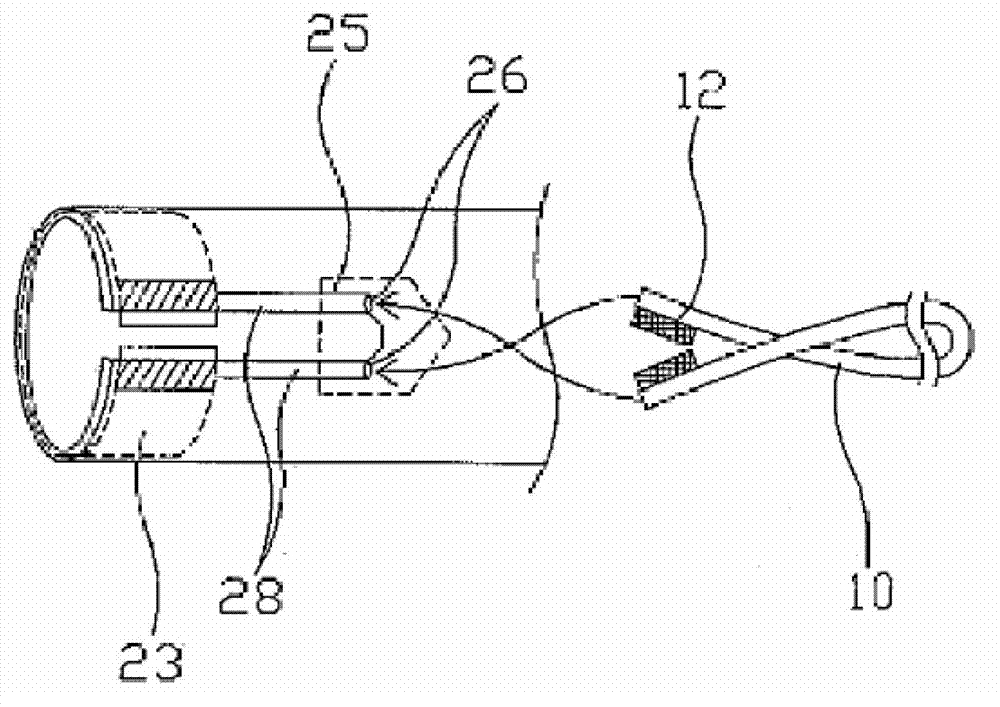

[0076] Preferably, the elastic component is a 'U'-shaped elastic pin 10, and the elastic pin 10 is composed of an elastic part 11, a leg part 13, and an adhesive part 12...

Embodiment 3

[0098] A new type of shirt, including a shirt main body 1, a sleeve main body 2, cuffs 20, elastic parts, and a cover 25;

[0099] The cuff 20 is composed of an outer lining 21, a fabric core 24, and an inner lining 22 in turn, and the outer lining 21 is fixedly connected with the fabric core 24; an insertion groove 27 is formed between the fabric core 24 and the inner lining 22;

[0100] The cuff 20 is in a 'C' shape, and the sleeve end 15 is provided with an opening along the extension direction of the sleeve body 2. The sleeve end 15 at the front end of the sleeve body 2 is fixedly connected to the cuff 20 by a suture 7, and the sleeve end The edge of the 15 opening is on the same horizontal line as the 'C' shaped edge of the cuff 20, and through insertion holes 28 are respectively arranged on both sides.

[0101] Preferably, the elastic member is The font elastic pin 10 is made up of an elastic part 11, a leg 13 and an adhesive part 12; the legs 13 of the elastic pin 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com