Deep filtration method of emulsion used by cold-rolling unit

A deep filtration and emulsion technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of limited filtration accuracy and filtration capacity, difficult to remove completely, and not very good filtration effect, etc., to improve filtration accuracy. , Overcome the effect of more sludge and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

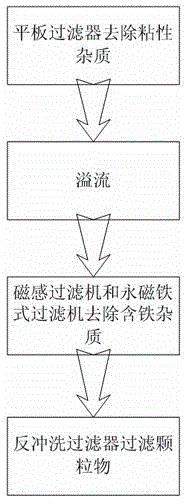

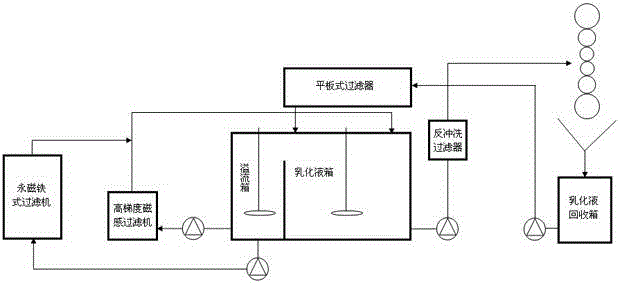

[0027] Such as figure 1 As shown, in the present embodiment, the filter system is adopted to carry out depth filtration to the cold rolling unit, wherein:

[0028] The emulsion tank and the overflow tank have an integrated structure, which is an all-steel structure, separated by a partition in the middle. Both the emulsion tank and the overflow tank are equipped with a mixer and a heating system;

[0029] The flat plate filter is mainly composed of filter cloth and filter pipe. The emulsion passes through the filter cloth, and impurities (mainly oil sludge, oil sludge and other sticky substances) are adhered by the filter cloth. If it cannot pass through smoothly, a pressure difference will be generated on the filter cloth and the pressure difference sensor will be triggered, and the impurities on the filter cloth will be blown away by compressed air to start the next filtration cycle.

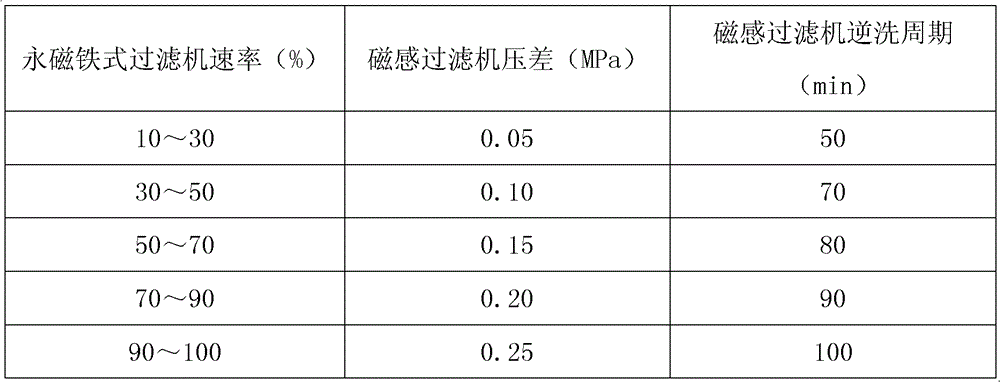

[0030] The filter element of the high-gradient magnetic induction filter (DEM) generates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com