Location method of curved-edge blank formed by hot stamping

A technology of hot stamping forming and positioning method, which is applied in the field of sheet metal stamping and forming, can solve the problem of inability to precisely control the placement position of the sheet metal, and achieve the effects of reducing trimming allowance, accurate positioning, and reducing wrinkling and cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

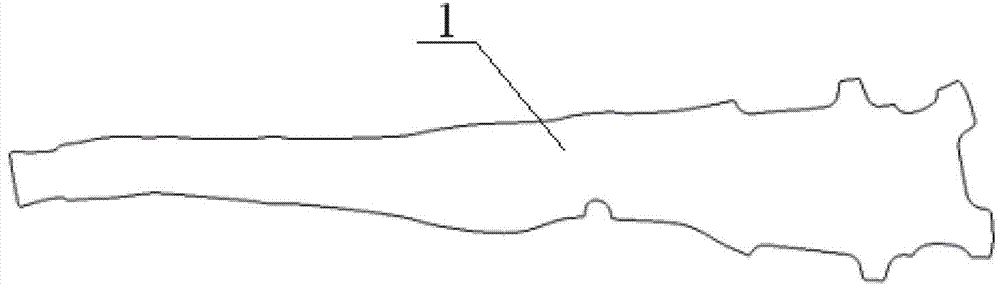

[0018] 1) According to the 3D surface digital model of the final design of the finished part, use the finite element inverse algorithm to calculate the precise blank 1 obtained after the part is expanded through the sheet metal before forming, such as figure 1 shown;

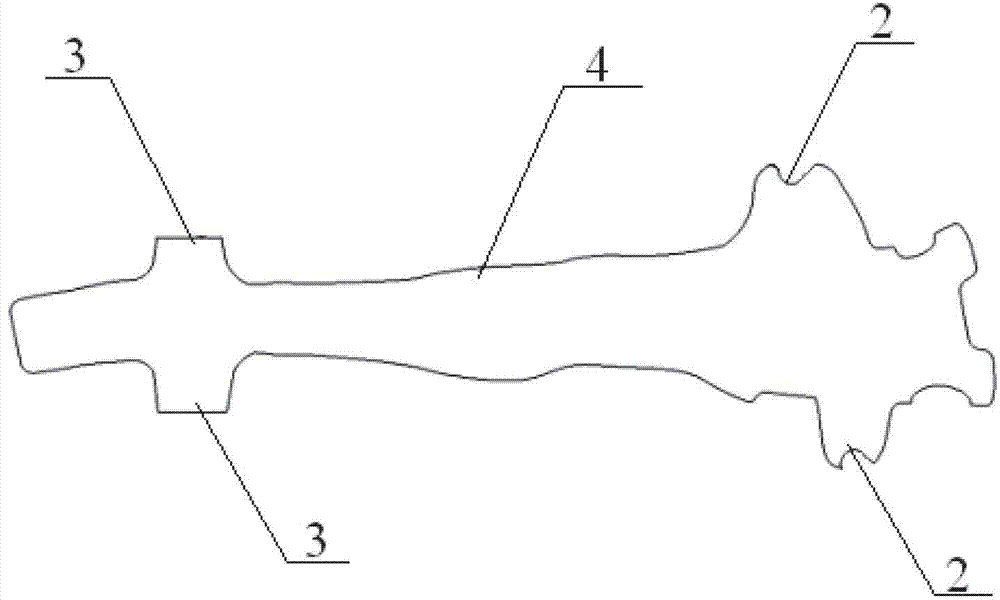

[0019] 2) Analyze the characteristic shape of the part, retain the positioning surplus material when the sheet is cut, form positioning ears 2 that limit the plane movement of the precise blank 1 on both sides of one end of the precise blank 1, and form a restrictive precision on both sides of the other end of the precise blank 1 The positioning surplus block 3 that blank 1 moves along the width direction obtains curved edge sheet 4, such as figure 2 As shown, the outside of the positioning ear 2 is a curved edge, and the outside of the positioning surplus block 3 is a straight edge; The shape of the bit block 5 is a cylinder with an inclined plane at the top;

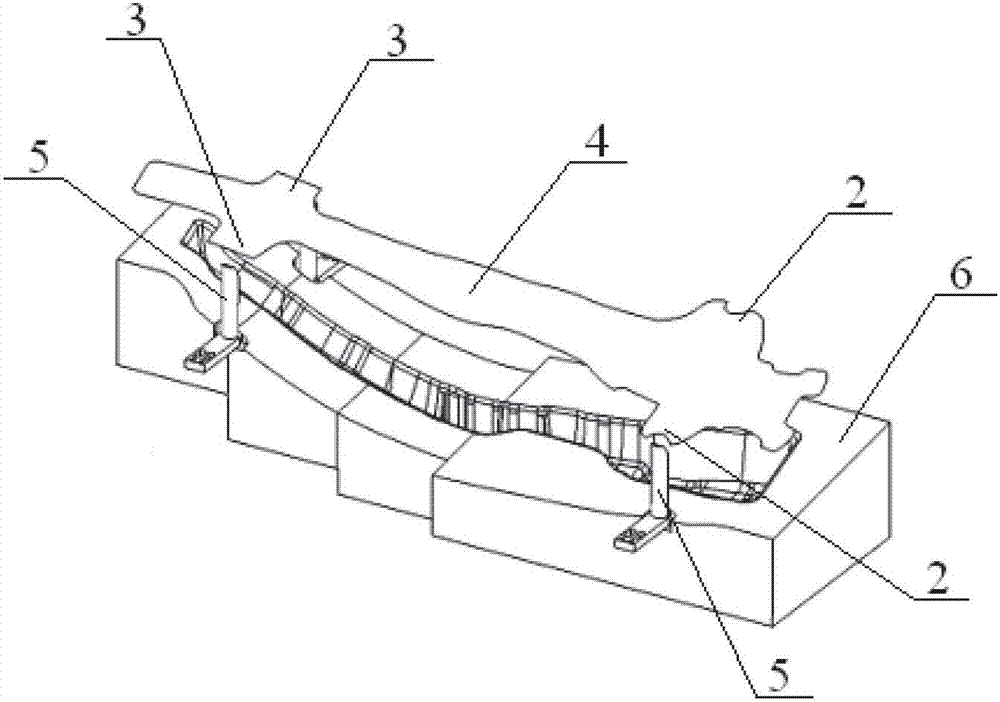

[0020] 3) if image 3 As shown, the curved edg...

Embodiment 2

[0022] 1) According to the 3D surface digital model of the final design of the finished part, use the finite element inverse algorithm to calculate the precise blank 1 obtained after the part is expanded through the sheet metal before forming, such as figure 1 shown;

[0023] 2) Analyze the characteristic shape of the part, keep the positioning surplus material when the sheet is cut, form the positioning ears 2 that limit the plane movement of the precise blank 1 on both sides of the middle of the precise blank 1, and form the restrictive precise blank on both sides of the two ends of the precise blank 1 1. Move the positioning block 3 along the width direction to obtain the curved edge sheet 4. The outside of the positioning ear 2 is a curved edge, and the outside of the positioning block 3 is a straight edge; 3 Install the sheet material limit block 5 at the corresponding position, and the shape of the sheet material limit block 5 is a cuboid with a slope at the top;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com