A flexographic cylinder transfer printing system and printing method

A transfer printing, roller type technology, applied in transfer printing, rotary printing machine, printing and other directions, can solve the problems of long product cycle, rising printing cost, energy, paper waste, etc., to shorten the cycle, reduce costs, and adapt to the market. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

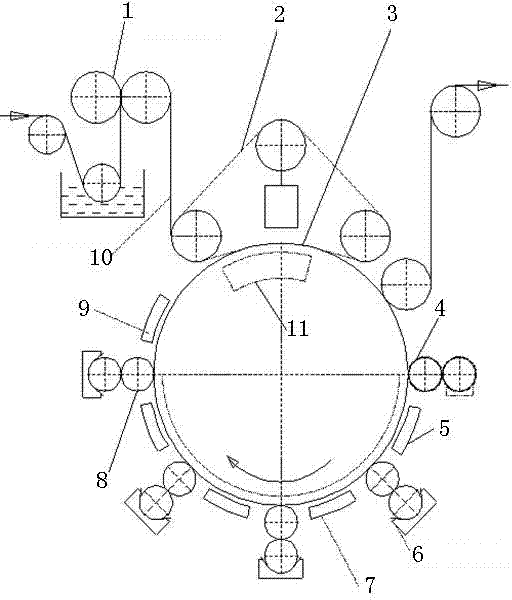

[0010] Example 1: Refer to the attached figure 1 . A flexographic cylinder transfer printing system. A tensioning blanket belt device 2 is arranged above the impression printing cylinder 3, and the first to Nth printing units (6, 9) are arranged at the lower and left side of the impression printing cylinder 3 , The first to Nth color ovens (6, 9) are set between the first to Nth printing units (6, 8), and the cleaning mechanism 4 is located in the middle of the right part of the impression printing cylinder 3. , The fabric pre-processing mechanism 1 is located on the side of the tensioning blanket belt device 2, and the printed fabric 10 processed by the fabric pre-processing mechanism 1 is guided by the guide roller and is in contact with the impression printing cylinder 3 under the action of the tensioning blanket belt device 2 After that, it is led out through the guide roller. The belt tensioning device 2 is composed of three or more guide rollers and a carpet belt, the t...

Embodiment 2

[0011] Embodiment 2: On the basis of embodiment 1, a flexographic cylinder transfer printing method, the impression printing cylinder 3 continuously rotates, and the first color printing unit 6 prints the first color of the printing pattern on the impression printing cylinder 3. The ink is dried in the first color oven 7; sequentially enters the n-th color printing unit 8 for printing of the n-th color printing pattern, and the printing ink is dried in the n-th color oven 9; after multi-color printing, the printing on the printing cylinder 3 is impressed The printed pattern is in close contact with the printed fabric 10 processed by the fabric pre-processing mechanism 1 and the carpet belt on the tensioning carpet belt device 2, and the transfer printing process is completed under the tension of the tensioning carpet belt device 2; if it is a thermal transfer During printing, a heating device 11 is installed inside the impression printing cylinder 3 to make the surface of the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com