On-vehicle electronic control apparatus

A vehicle-mounted electronic control and vehicle-mounted battery technology, applied in the direction of circuit devices, battery circuit devices, collectors, etc., can solve the problems of increased cost and power consumption of regulated power supply circuits, and achieve low consumption, stable power supply, and low power consumption. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0063] (1) Structure description

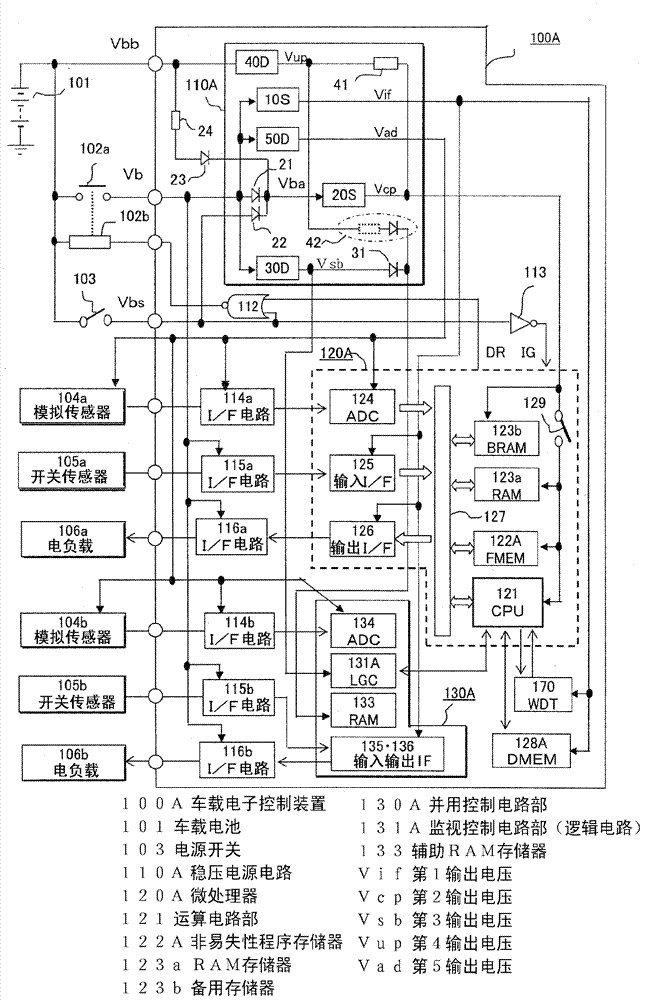

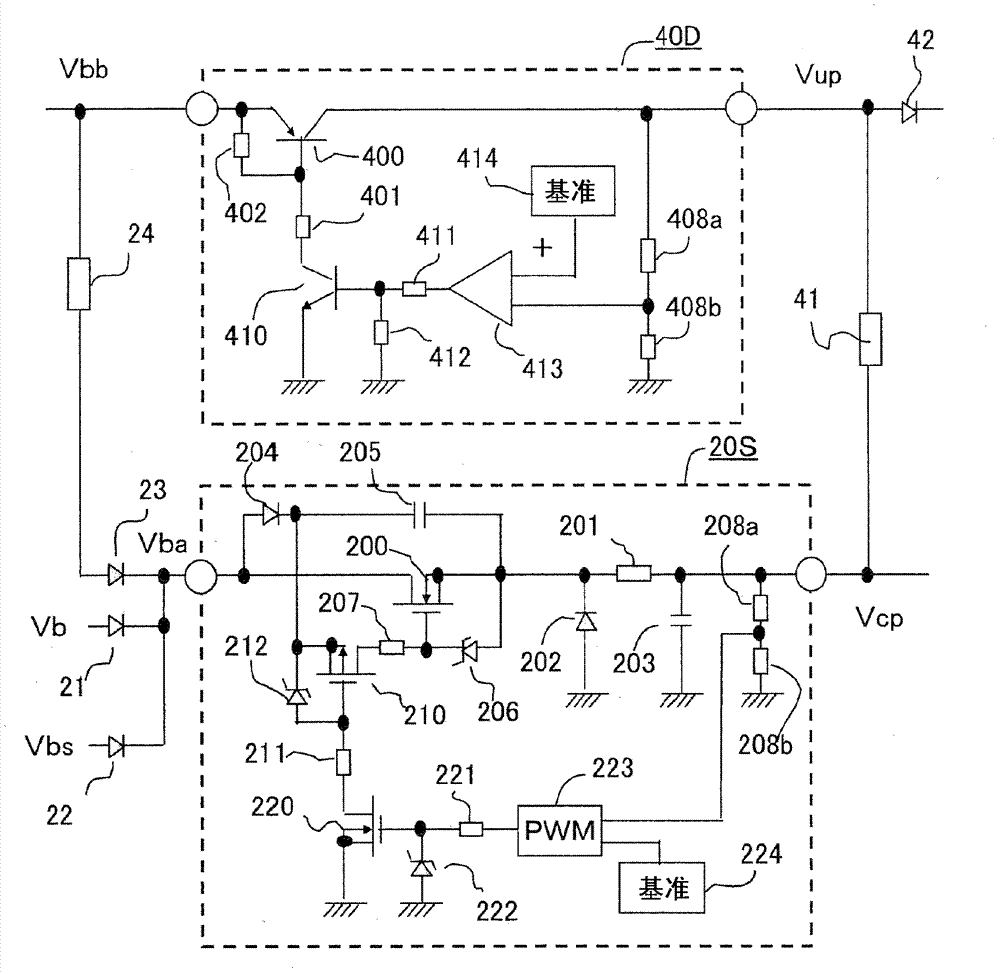

[0064] figure 1 It is a block diagram of the overall circuit of the in-vehicle electronic control device according to Embodiment 1 of the present invention. exist figure 1 Among them, the main power supply voltage Vb is applied from the on-vehicle battery 101 to the on-vehicle electronic control device 100A through the output contact 102a of the power relay, and even when the output contact 102a is open, the holding power supply voltage Vbb can be directly applied from the on-vehicle battery 101. However, since the direct power supply line uses a thin wire for relatively small power, there is a problem that the line voltage drops even if a large current flows temporarily. The excitation coil 102b of the power relay is controlled by the on-vehicle electronic control unit 100A so that it is excited when the power switch 103 is turned on, and de-energized after a predetermined time delay when the power switch 103 is turned off. The first anal...

Embodiment approach 2

[0116] (1) Structure description

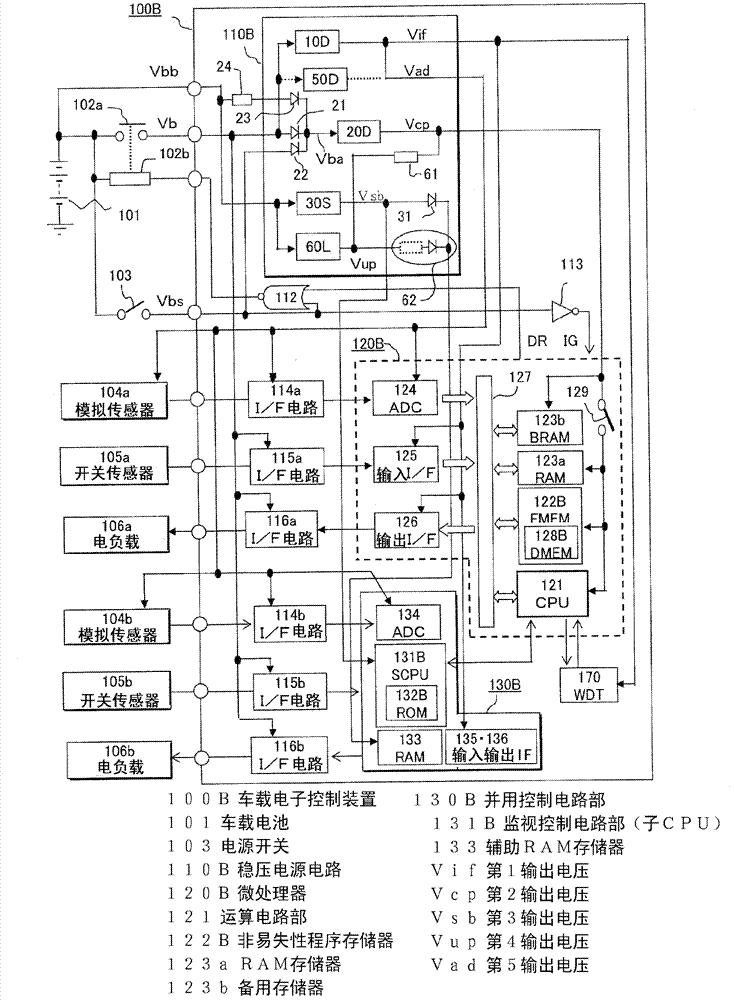

[0117] For the vehicle-mounted electronic control device according to Embodiment 2 of the present invention, refer to the overall circuit diagram that is image 3 , and a detailed circuit diagram of a part of the regulated power supply circuit is Figure 4 , with figure 1 , figure 2 The differences will be explained centering on. Furthermore, in the figure, with figure 1 , figure 2 The same reference numerals represent the same or corresponding parts.

[0118] exist image 3 In, for the vehicle electronic control device 100B with figure 1 Same as the vehicle battery 101, the output contact 102a of the power relay, the exciting coil 102b, the power switch 103, the first analog sensor 104a, the second analog sensor 104b, the first switch sensor 105a, the second switch sensor 105b, the first vehicle sensor The electric load group 106a is connected to the second on-vehicle electric load group 106b, and the main power supply voltage Vb, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com