Cement-based infiltration crystalline waterproof material

A technology of infiltrating crystalline and waterproof materials, applied in the field of building materials, can solve the problems of different quality of materials, restrict the development of materials, and cannot be guaranteed, and achieve the effect of moderate price, wide range of use, and delaying rust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

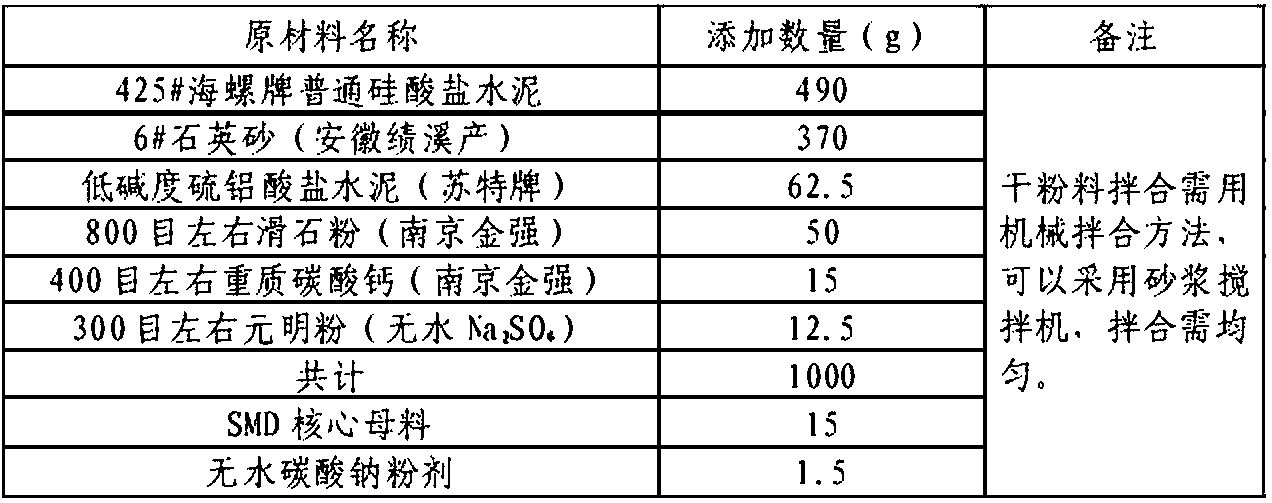

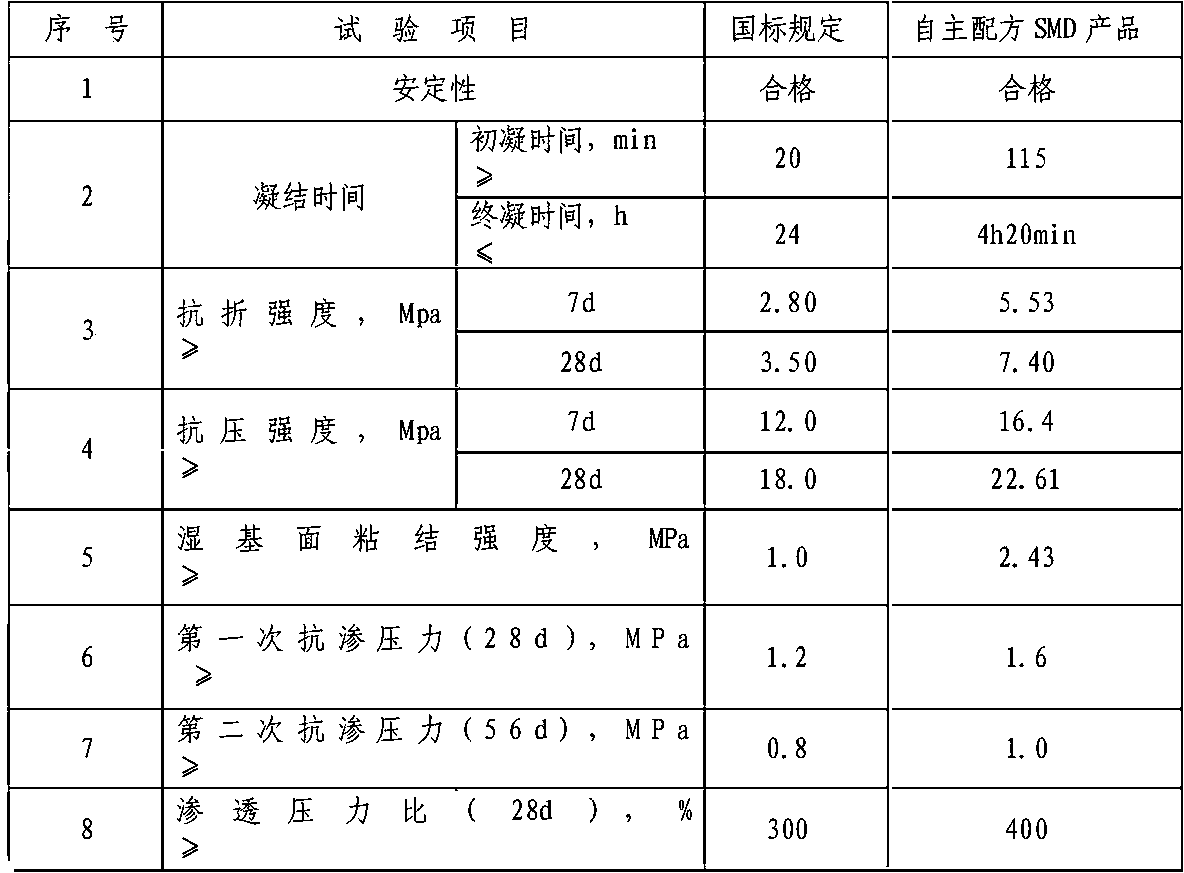

[0014] see figure 1 , a cement-based permeable crystalline waterproof material, its components and their weight ratios are: 425# ordinary Portland cement: 6# quartz sand: low-alkalinity sulphoaluminate cement: 700-900 mesh talcum powder: 300-500 mesh heavy calcium carbonate: 200-400 mesh anhydrous Na 2 SO 4 : SMD core masterbatch: anhydrous sodium carbonate powder = 490: 370: 62.5: 50: 15: 12.5: 15: 1.5

[0015] When using small-area scraping, the dry powder of the above components can be mixed according to the weight ratio, then mixed with water according to the gray-to-water ratio of 1:0.3, and mixed evenly by manual or mechanical mixing. It is best to use an electric mixer to stir and reconcile. Apply to a thick paste. Strictly implement the construction while mixing. Generally, the amount of powder for each mixing is 3kg, and it will be used up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com