Liquid crystal composition containing polymerizable compound and liquid crystal display element manufactured using the same

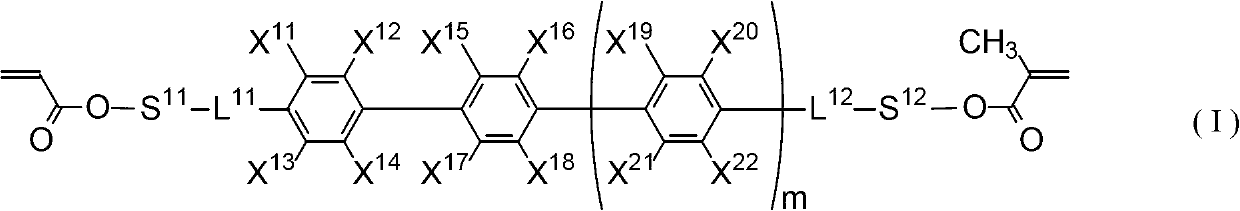

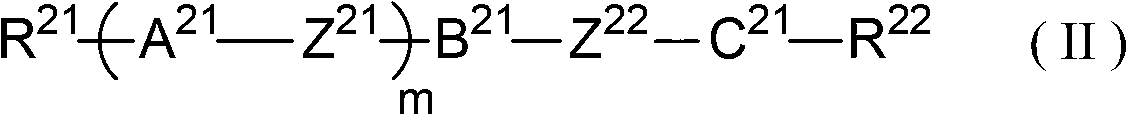

一种聚合性化合物、液晶组合物的技术,应用在液晶材料、非线性光学、化学仪器和方法等方向,能够解决难以满足快速响应特性图像残留特性、取向稳定性稳定性PSA型液晶显示元件制造效率、液晶化合物相溶性低等问题,达到显示不良减轻、不良影响减少、提高成品率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

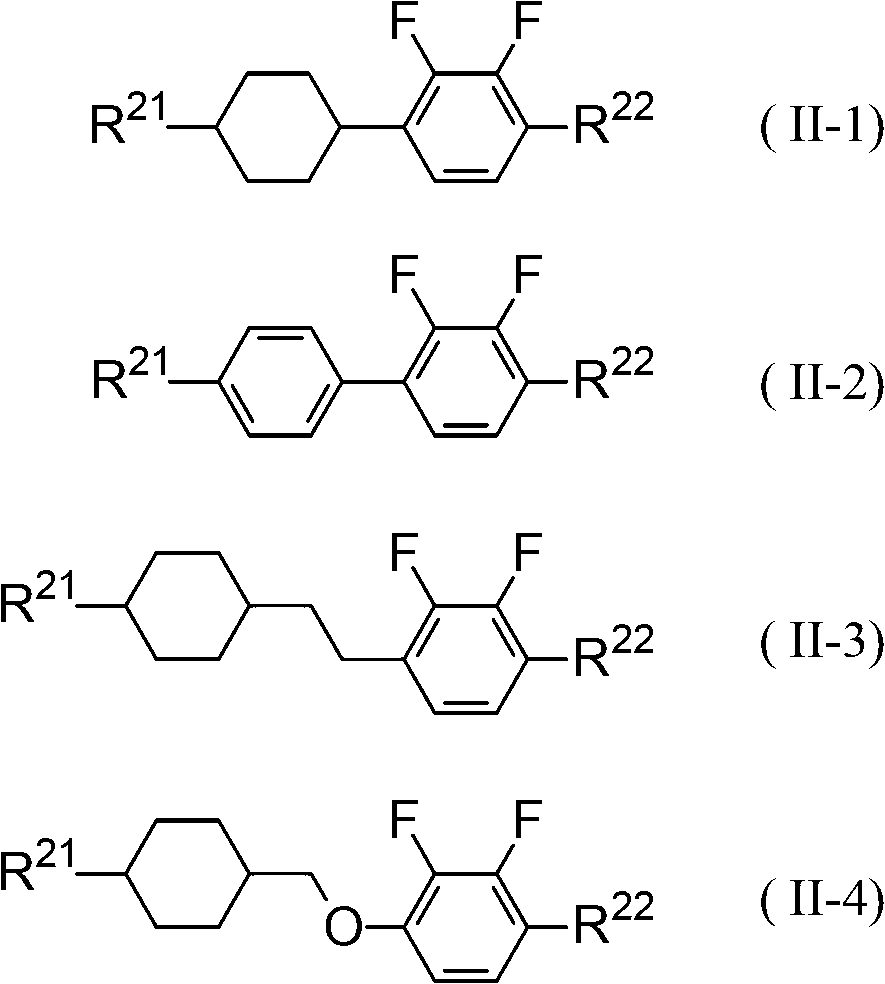

[0088] Preparation of a liquid crystal composition LC-1 containing a compound selected from the general formula (II) and a compound selected from the general formula (III),

[0089]

[0090] In 99.7% LC-1, add 0.3% formula (I-1-1)

[0091] Formula (I-1-1)

[0092] The polymeric compound shown was prepared to prepare the liquid crystal composition CLC-1 containing the polymeric compound. Next, the prepared polymerizable compound-containing liquid crystal composition CLC-1 and its physical property values are shown.

[0093] The liquid crystal composition CLC-1 containing the polymerizable compound is, T ni : 74.1°C, Δn: 0.101, Δε: -3.0.

[0094] Using a vacuum injection method, CLC-1 was injected into an ITO-attached cell having a cell gap of 3.5 μm and coated with a polyimide alignment film for inducing homeotropic alignment. After measuring the pretilt angle of the cell (crystal rotation method), while applying a 1.8V rectangular wave at a frequency of 1kHz, the li...

Embodiment 2)

[0113] Preparation of a liquid crystal composition LC-2 containing a compound selected from the general formula (II) and a compound selected from the general formula (III),

[0114]

[0115] In 99.7% LC-2, add 0.3% formula (I-6-1)

[0116] Formula (I-6-1)

[0117] With the polymeric compound shown, the liquid crystal composition CLC-2 containing a polymeric compound was prepared.

[0118] The physical property value of the liquid crystal composition CLC-2 containing a polymerizable compound is T ni : 77.0°C, Δn: 0.103, Δε: -3.2.

[0119] Except having used CLC-2, it carried out similarly to Example 1, and obtained the vertical alignment liquid crystal display element. The response speed of this liquid crystal display element is 4.7 milliseconds.

[0120] The content of the unpolymerized polymerizable compound represented by the formula (I-6-1) contained in the device was analyzed by liquid chromatography, but it was not detected. From this, it was confirmed that the po...

Embodiment 3)

[0122] preparing a liquid crystal composition LC-3 containing a compound selected from the general formula (II) and a compound selected from the general formula (III),

[0123]

[0124] In 99.7% LC-3, add 0.3% formula (I-13-1)

[0125]

[0126] The polymeric compound shown was prepared to prepare the liquid crystal composition CLC-3 containing the polymeric compound.

[0127] The physical property value of the liquid crystal composition CLC-3 containing a polymeric compound is T ni : 76.4°C, Δn: 0.090, Δε: -2.9.

[0128] Except having used CLC-3, it carried out similarly to Example 1, and obtained the vertical alignment liquid crystal display element. The response speed of this liquid crystal display element was 5.0 milliseconds.

[0129] The content of the unpolymerized polymerizable compound represented by the formula (I-13-1) contained in the element was analyzed by liquid chromatography analysis, but it was not detected. From this, it was confirmed that the polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com