Floating structure connected by tension connector with adjustable length

A technology for adjusting the length of floating structures, which is applied to floating buildings, pontoon bridges, bridge parts, etc., can solve the problems of uneven joint gap, uneven force on joints, large bending moments at rigid joints, etc., and achieve manufacturing accuracy less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

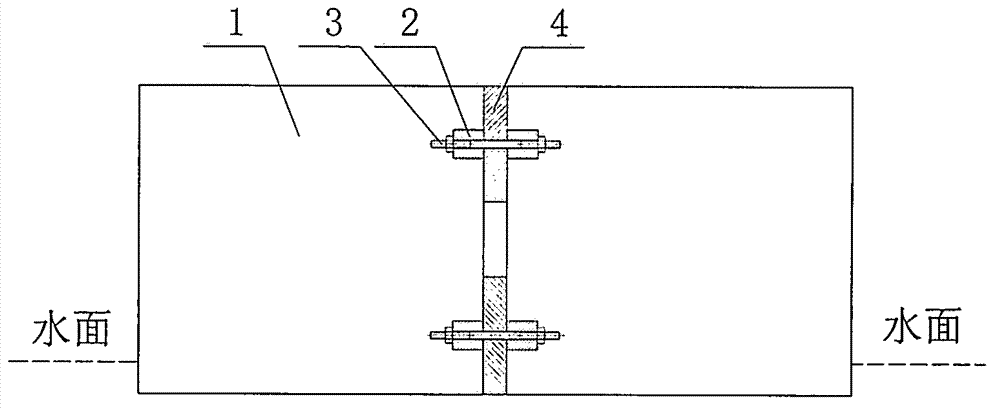

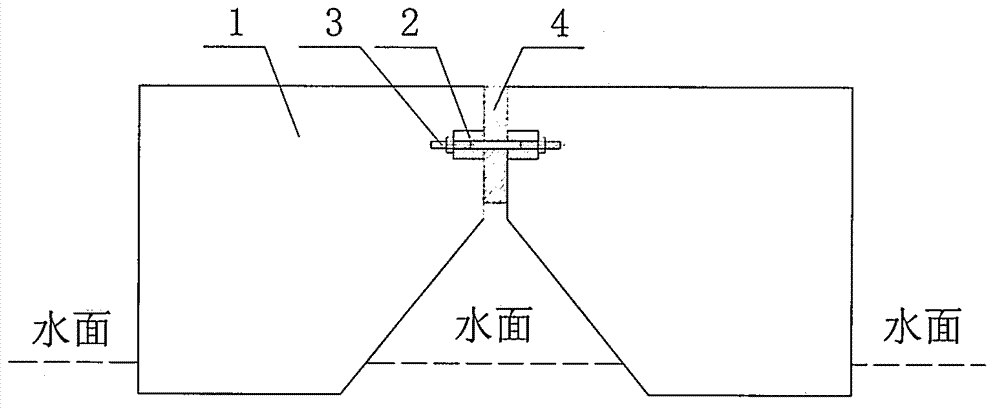

[0010] figure 1 Among them, the connecting surface of the floating body unit (1) is provided with upper and lower two-layer connector mounts (2), after the adjustable-length tension connector (3) is inserted into the connector mount (2), tighten the connector nut , and achieve the same degree of tightness of the tension connectors (3) on the same connecting surface. Each layer can be installed with multiple tension connectors according to the force requirements. Since the elastic buffer material (4) is installed between the corresponding floating body units (1), when the nut of the connector is tightened, the tension connector (3) is subjected to a certain initial tension, and the elastic buffer material (4) is subjected to a certain initial pressure effect, so that there will be no impact effect between the connection between the traditional pontoon bridge and the pontoon. figure 1 Only the tension connectors installed horizontally are shown in the figure. Since the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com