Integrated construction method of support of large cantilevered capping beam and vertical column

A construction method and column technology, which is applied in the field of integrated construction of large cantilever cover beams and column supports, can solve the problems of column appearance damage, welding safety and reliability hidden dangers, and inapplicability, so as to enhance safety and stability and save energy. The effect of construction materials and labor usage, speeding up the construction schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below through specific embodiments.

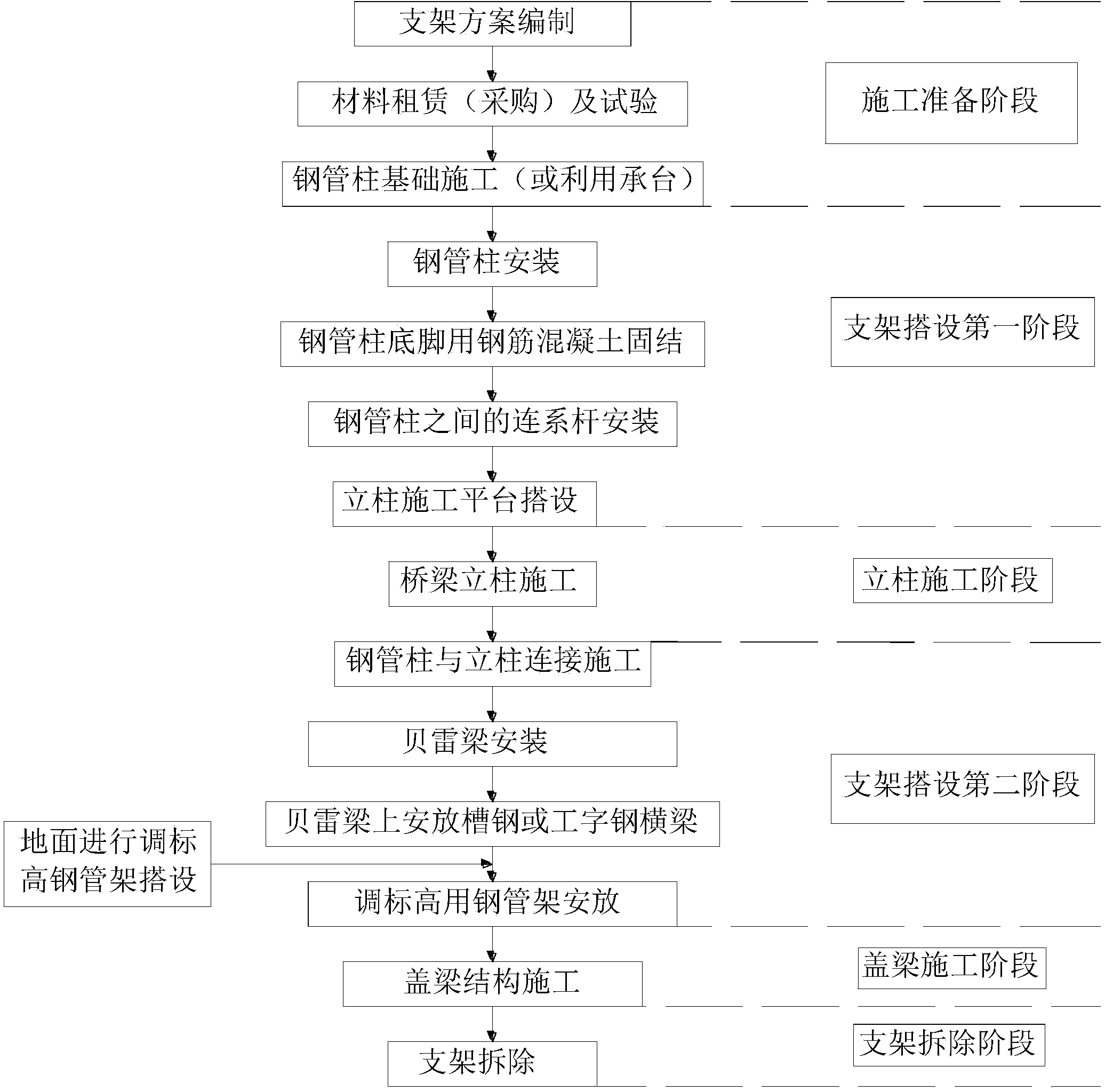

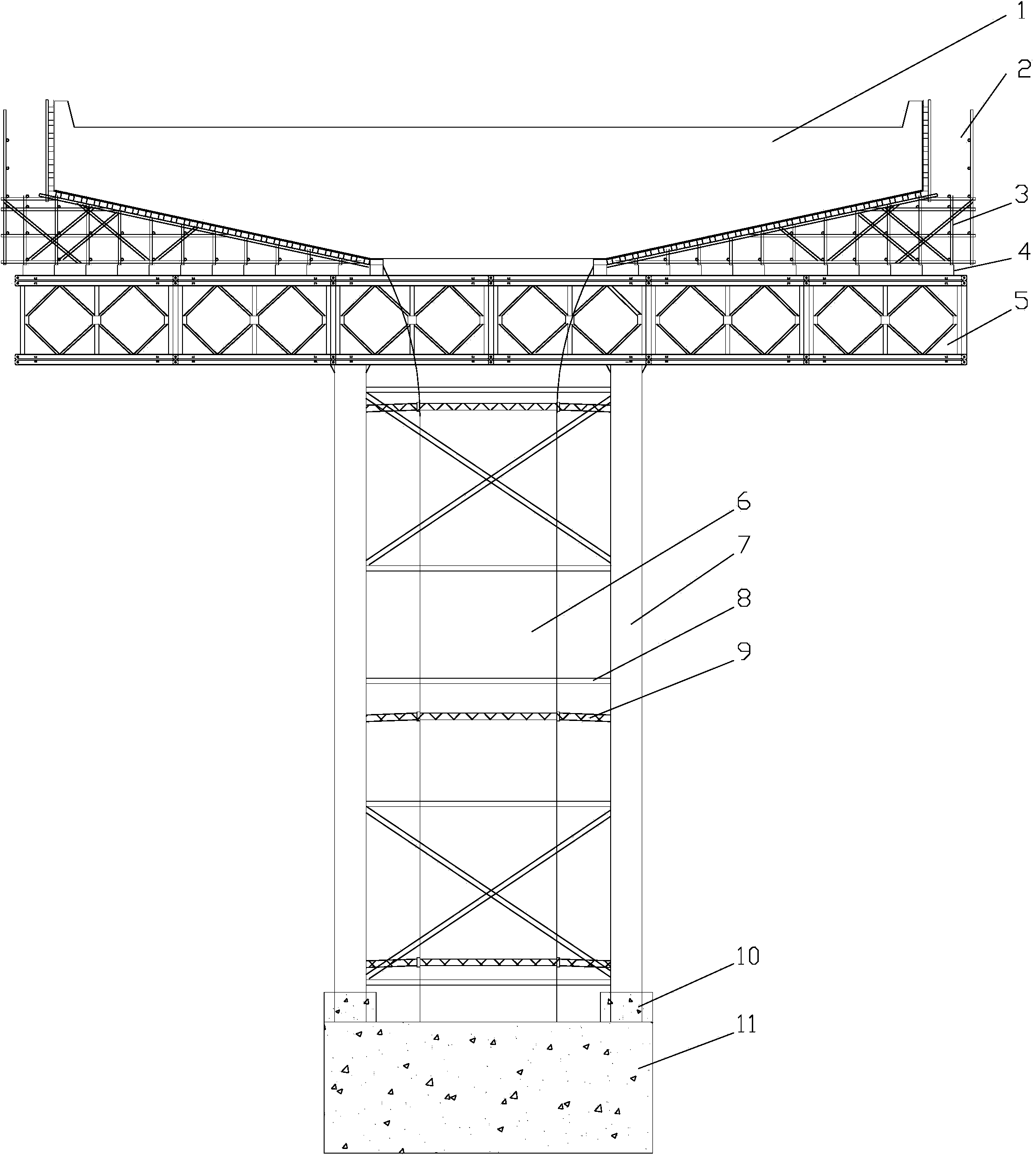

[0028] Such as figure 1 As shown, the integrated construction method of the support of the large cantilever cover beam and the column of the present invention includes the following stages in sequence: construction preparation stage, the first stage of support erection, the column construction stage, the second stage of support erection, and the cover beam Construction phase and support removal phase;

[0029] 1. Construction preparation stage:

[0030] 1. Scaffold scheme preparation

[0031] The large cantilever cover beam structure of the high column bridge adopts the steel pipe column Bailey beam composite support system. According to the "Building Structure Load Code" (GB50009-2001), the construction load of the cap beam structure is calculated, and the maximum shear force and bending moment of the Bailey beam, and the maximum stress value of the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com