IrOx electrode prepared through cyclic thermo oxidation method

A thermal oxidation, electrode technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

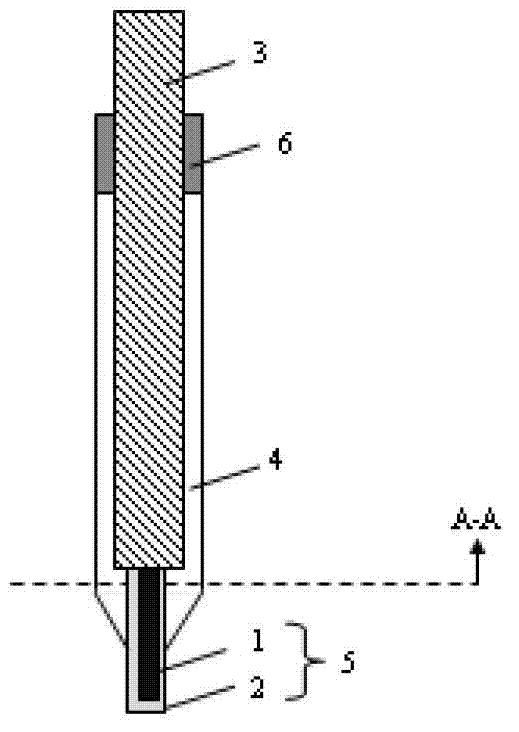

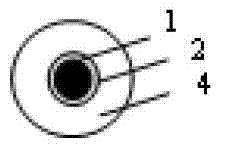

[0032] Embodiment 1: as figure 1 , 2 Shown is an embodiment of the unipolar iridium oxide electrode with one electrode core (5) of the present invention. The IrO prepared by the cyclic thermal oxidation method x electrode, which encapsulates an IrO x Electrode core (5); one end of the electrode core (5) is prepared by cyclic thermal oxidation on the outer surface of the iridium metal core (1) to generate a layer of IrO x The conductor of the film (2); the other end of the electrode core is composed of a wire (3); the IrO x When the electrode core (5) is encapsulated in the insulating layer (4), a part of the exposed outside is used for pH sensing. The size of the electrode core (5) can be changed within a certain range. When the size is small, it can be made into a microelectrode, and when the size is large, it can be made into a common electrode.

[0033] The iridium metal core (1) can be metal iridium wire, metal iridium sheet or metal iridium powder consolidated togeth...

Embodiment 2

[0036] Embodiment 2: The difference from the above embodiment is that the electrode core (5) can be prepared as an array of at least two IrO x electrode core.

[0037] A kind of IrO prepared by the cyclic thermal oxidation method adopted by the present invention x The manufacture method of electrode, it comprises the steps:

[0038] A. Clean and pre-treat the surface of the iridium metal core (1). The pretreatment is to carry out ultrasonic cleaning in acid solution first, and then carry out ultrasonic cleaning in deionized water.

[0039] B. Soak the pretreated iridium metal core (1) in the solution to activate the metal surface. The soaking solution is concentrated alkali;

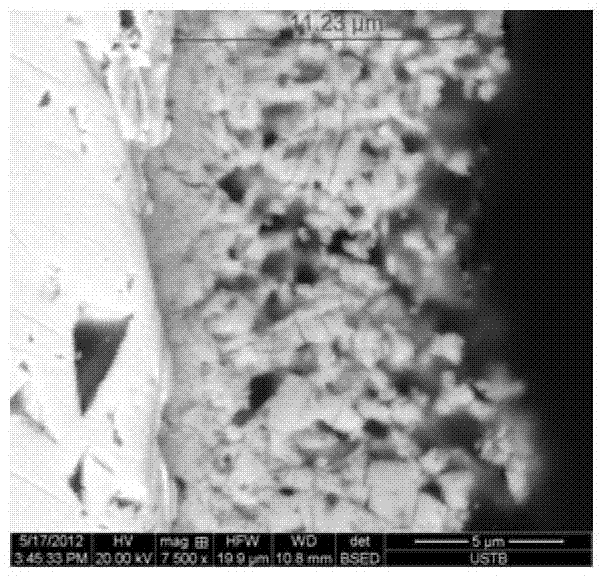

[0040] C. The soaked iridium metal core (1) is heated at a constant temperature in a high temperature environment for a period of time, and then quenched immediately after taking it out; the high temperature treatment temperature is 700~850°C, and the heating time is 30min~2h; the quenching The medi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap