Probe mechanism of oil and gas pipeline crack detector

A technology for oil and gas pipelines and detectors, applied in instruments, measuring devices, scientific instruments, etc., to ensure the effect of detection accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

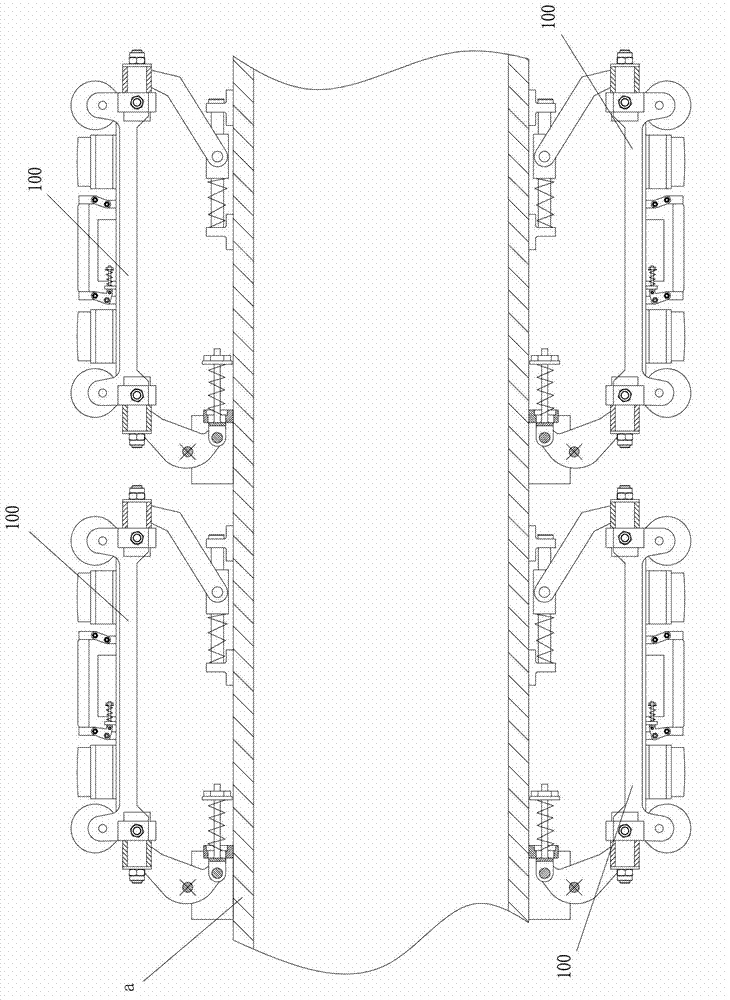

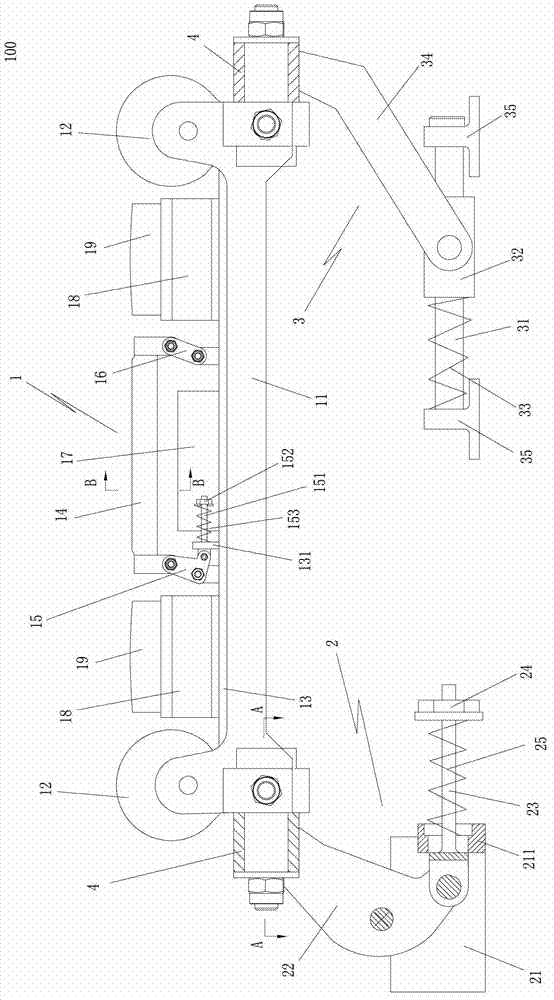

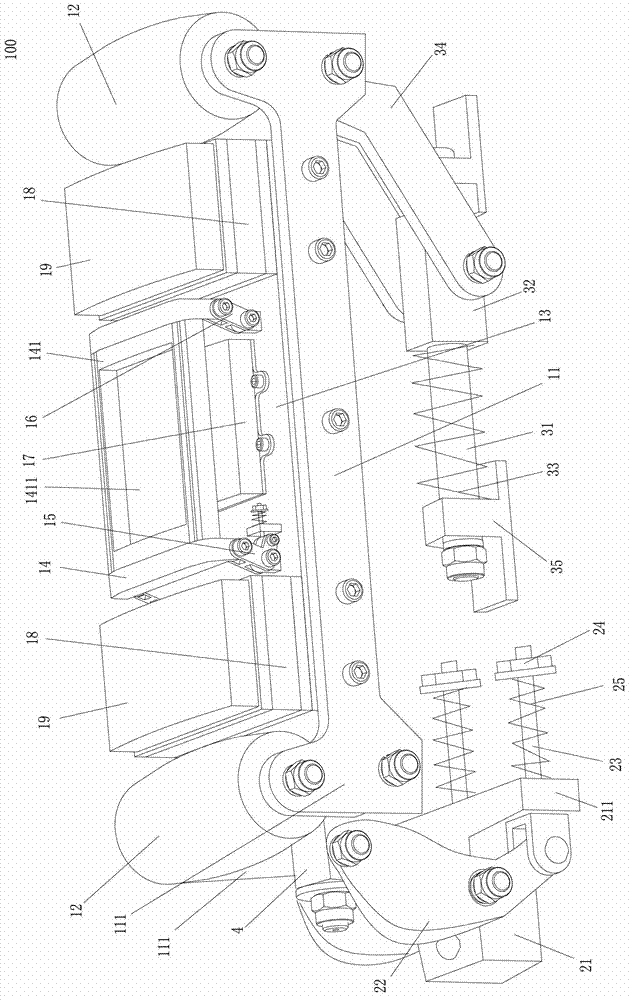

[0026] Such as figure 1 , figure 2 , image 3 As shown, the present invention proposes a probe mechanism 100 for an oil and gas pipeline crack detector. The probe mechanism 100 is installed on the frame a of the crack detector. A plurality of the probe mechanisms 100 can be provided on the pipeline crack detector. Each probe mechanism has an independent signal acquisition probe to collect crack data; the number of probe mechanisms on the oil and gas pipeline crack detector is determined by the detection sensitivity of the probe, the length of the signal coverage, the length of the blind zone and the diameter of the measured pipe In this embodiment, the entire crack detector has a total of 16 probe mechanisms, divided into two rows, 8 in each row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com