Coal mine working face detecting method with cutting vibration as seismic signal

A technology of seismic signal and detection method, which is applied in seismic signal processing, seismology for logging records, etc., can solve the problem of insufficient safety of explosives, and achieve the effect of high source energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

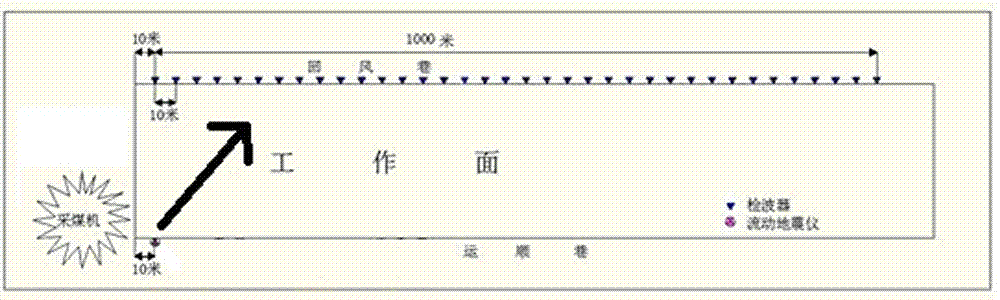

[0033] 1) Arrange geophones on the side walls of the return air lane and Yunshun lane ( figure 1 ), the geophone is connected to the center of the coal seam or close to the center of the bolt outcrop with a specially designed butt joint, and the surroundings are tightened and fixed with nuts. The distance between the geophones is generally 11m.

[0034] 2) After the geophones, large wires, instruments, etc. are laid out, when the shearer starts cutting work, the recording system is started, and the data is transmitted to the processor in real time.

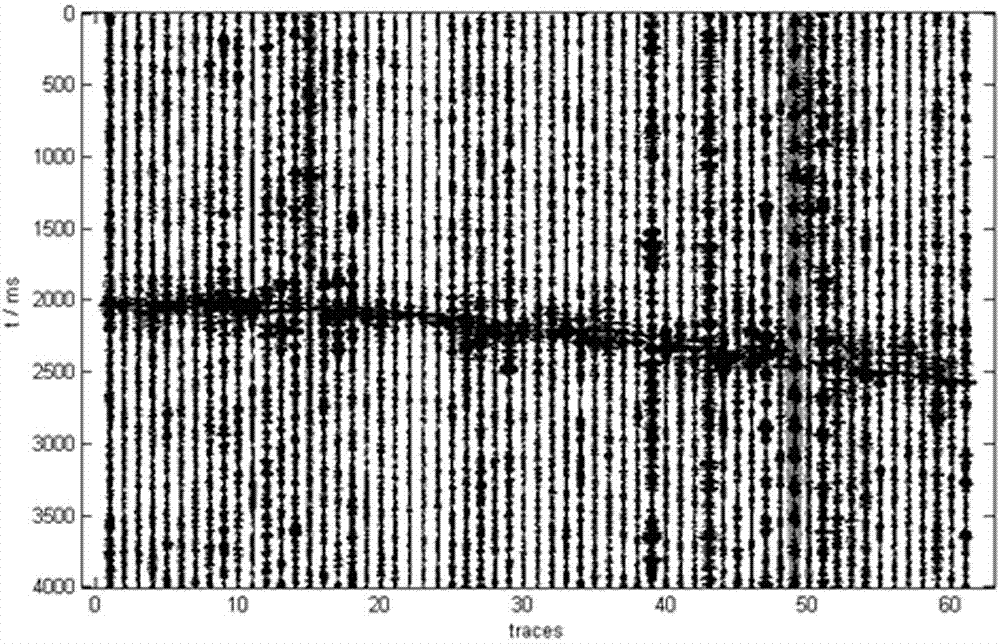

[0035] 3) To process the data, first establish the observation system ( figure 1 ), using seismic interferometry technology to convert mechanical noise into effective seismic signals, and do preliminary processing on the data: adaptive filtering, eliminating roadway surface waves; seismic interferometry processing, converting continuous vibration signals into pulse signal shots; bandpass filtering, Separation of groove waves with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com