Annular micro-fold optical lens and preparation method thereof

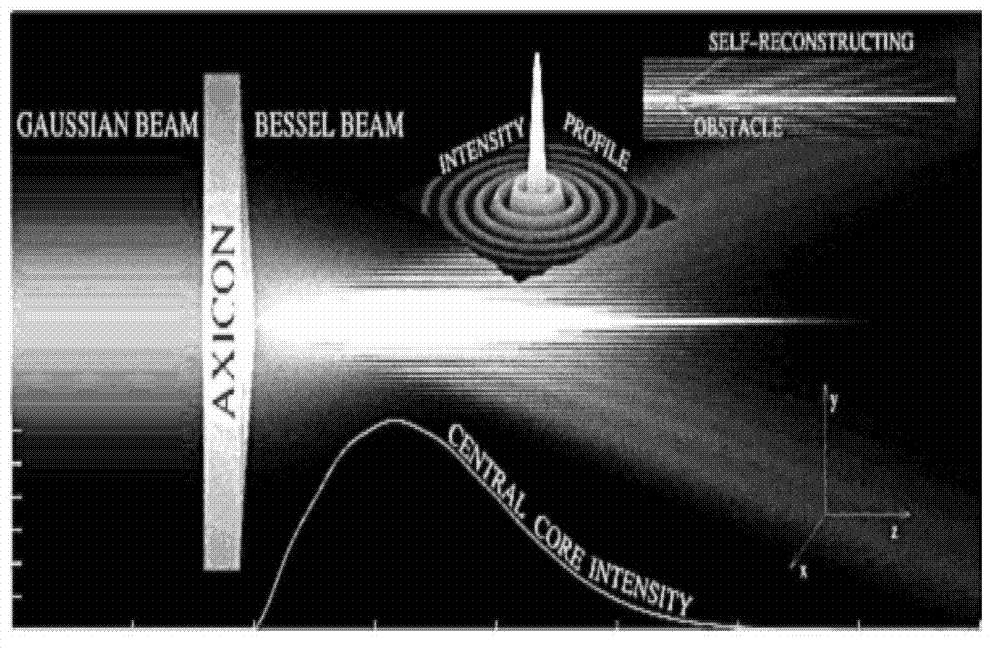

An optical lens and wrinkle technology, which is applied in the field of annular micro-folded optical lens and its preparation, can solve the problems of high processing cost of diffractive optical elements, difficulty in making large-area lenses, and large-area lenses and heavy weight, etc., and achieves light weight and low cost. The effect of processing cost and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

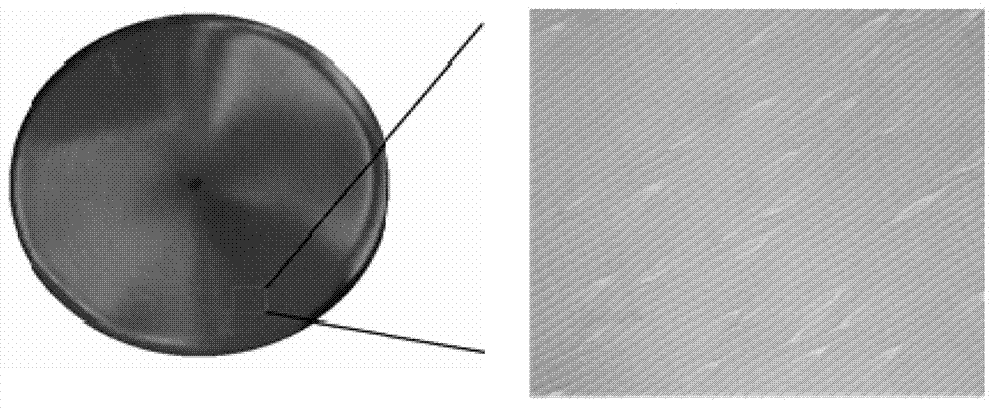

[0040] see Figure 2~Figure 6b , the present embodiment provides a method for preparing an annular micro-wrinkled optical lens, the preparation method at least comprising:

[0041] Such as Figure 2~Figure 3b As shown, step 1) S11 is first performed, providing a substrate 102 with holes 1021 of a predetermined shape and a predetermined size on the surface and a soft material film 101, and fixing the soft material film 101 on the surface of the substrate 102, And make the soft material film 101 cover the hole 1021 .

[0042] The substrate is a glass substrate, and the hole 1021 of the substrate 102 is a circular hole with a diameter of 0.1 to 200 cm. In this embodiment, the diameter of the circular hole is 1.4 cm. 101 is fixed on the surface of the base 102. Of course, in other embodiments, the hole 1021 can be polygonal, rounded polygonal or any expected shape, and its size can also be determined according to actual needs. Larger or smaller size holes 1021 are used to prepare...

Embodiment 2

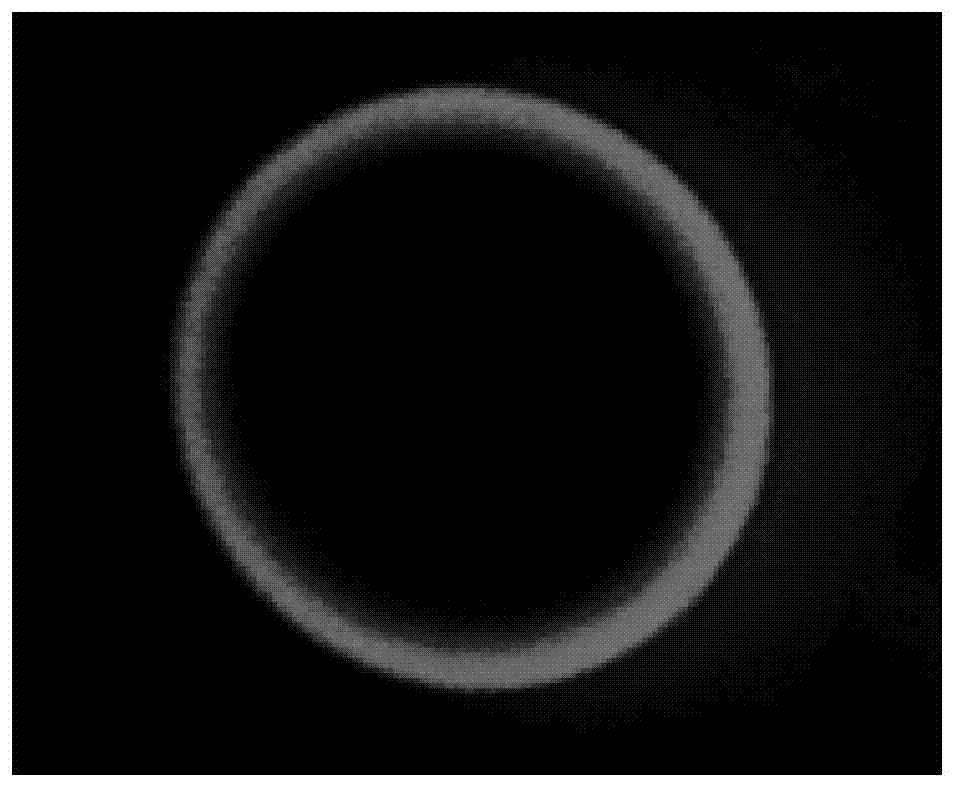

[0059] see Figure 6a~6b , as shown in the figure, this embodiment provides an annular micro-wrinkled optical lens, at least including: a soft material film 101, the surface of which has a predetermined period of annular micro-wrinkles 104; a hard material film 103, combined with the soft material film 101 surface, which has the same annular microfold 104 as the period of the soft material film 101, its cross-sectional view is as follows Figure 6a As shown, the top view is as Figure 6b shown.

[0060] In this embodiment, the soft material film 101 is a polydimethylsiloxane film, and the hard material film is a gold film 103 . Of course, in other embodiments, the soft material film 101 and the hard material film 103 different from the present embodiment can be selected to meet the required requirements.

[0061] The preset period T (the distance between the valley peaks or valley bottoms of two adjacent annular microfolds) is 0.2-30 μm. In this example, it is 2 μm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com