Permanent magnet auxiliary synchronized reluctance motor rotor and motor thereof and installation method of motor

A technology for assisting synchronous and reluctance motors, which is applied to synchronous motors with stationary armatures and rotating magnets, electromechanical devices, and manufacturing motor generators. Problems such as the demagnetization current of the permanent magnets in each layer, to achieve the effect of improving operation reliability and anti-demagnetization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

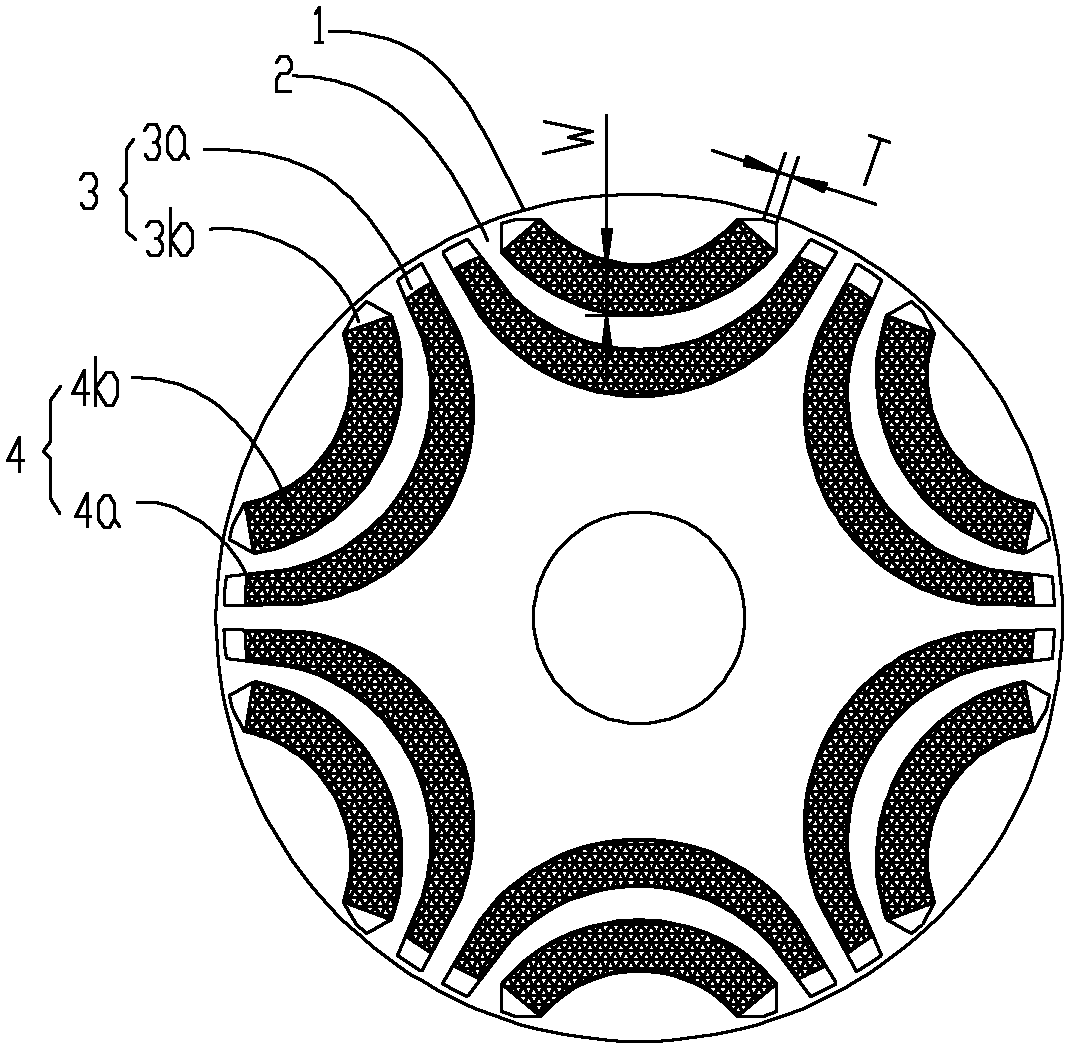

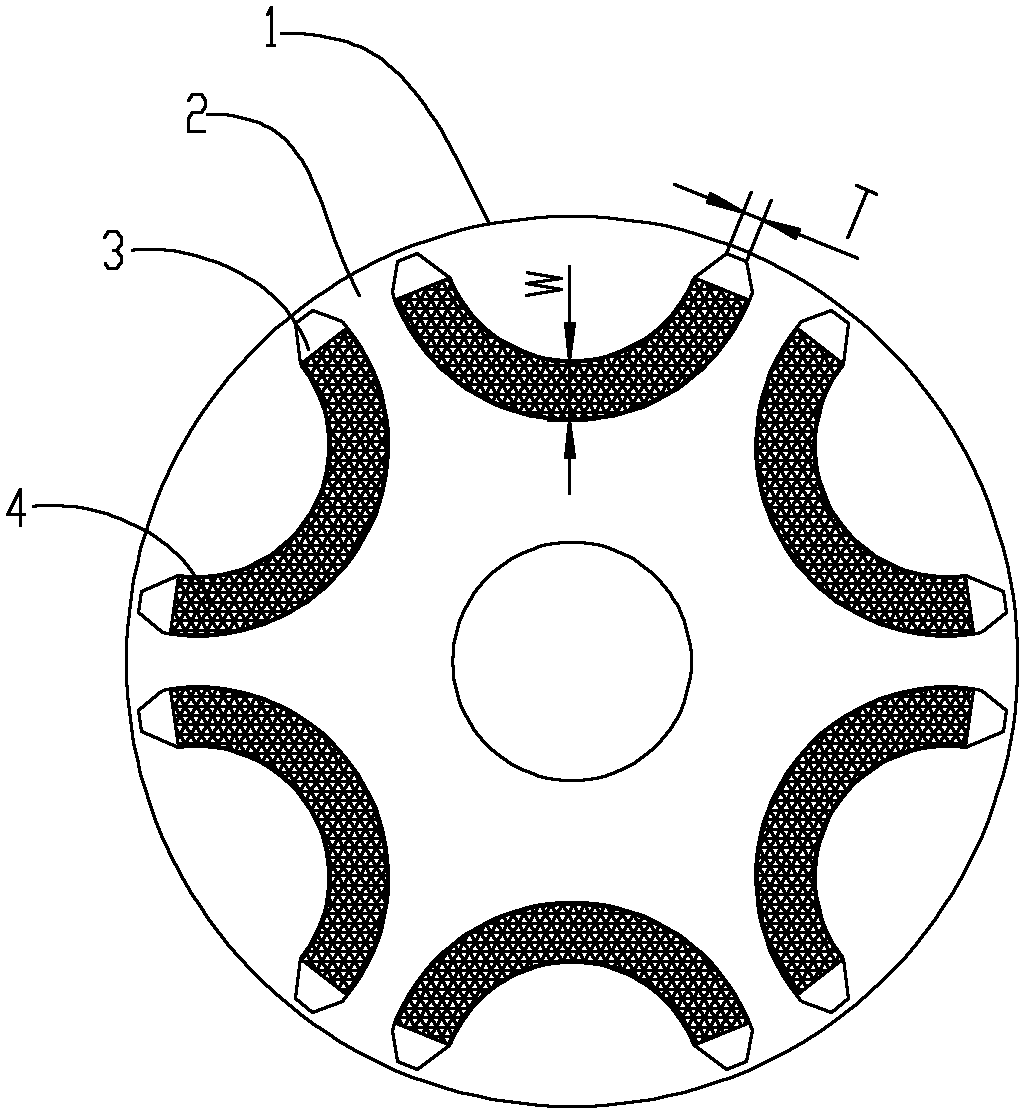

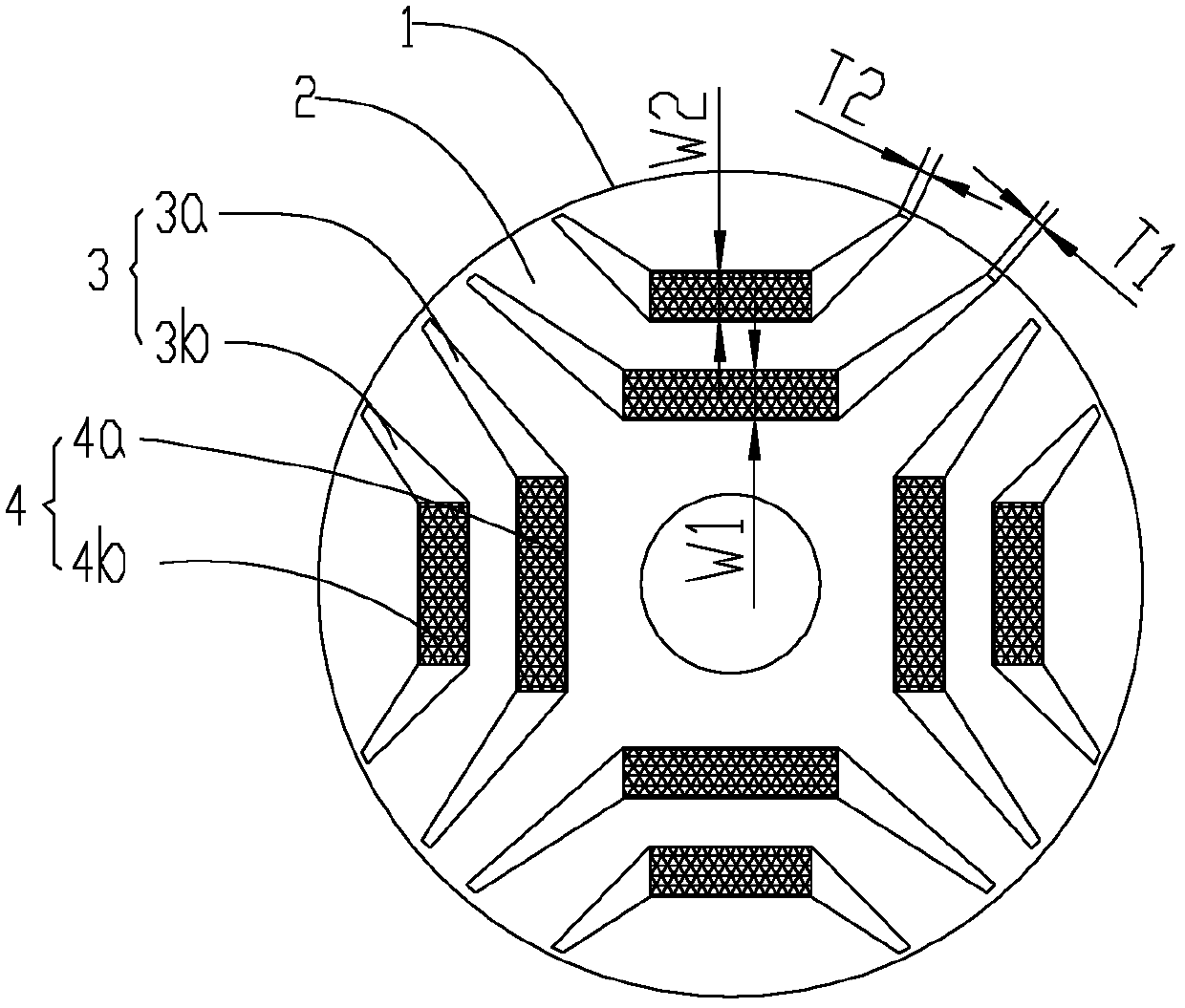

[0027] figure 1 The rotor of the permanent magnet assisted synchronous reluctance motor according to the first embodiment of the present invention is shown. The rotor has six permanent magnet groups, that is, six poles, each permanent magnet group has two layers of permanent magnets, and both the permanent magnet slots and the permanent magnets are arc-shaped. The following reference figure 1 and Figure 6 The first embodiment will be specifically described.

[0028] The rotor 1 of the permanent magnet assisted synchronous reluctance motor of the first embodiment includes a rotor core 2 and a plurality of permanent magnet groups. The rotor core 2 is made of laminated silicon steel plates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com