Bistable composite cantilever beam piezoelectric power generating device

A composite cantilever beam and piezoelectric power generation technology, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problems of poor environmental adaptability, small power generation, and power generation efficiency. Low-level problems, to achieve the effect of wide operating frequency and increase power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

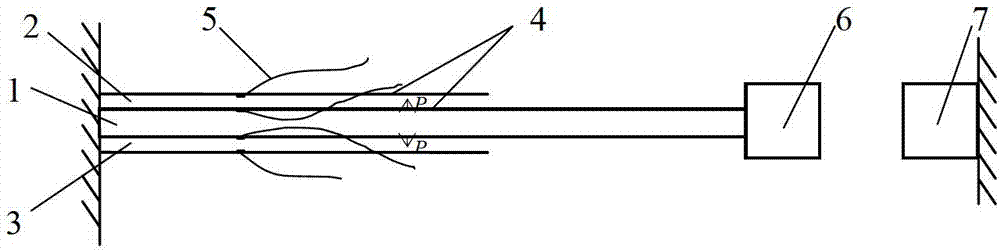

[0029] figure 1The structure of the bistable piezoelectric cantilever vibrator in the present invention is shown, including a bimorph piezoelectric cantilever beam 1, and the upper and lower surfaces of the bimorph piezoelectric cantilever beam 1 are respectively pasted with a first piezoelectric layer 2 and a second piezoelectric layer. Two piezoelectric layers 3; the first piezoelectric layer 2 and the second piezoelectric layer 3 have the same width as the elastic beam on the bimorph piezoelectric cantilever beam 1, and the first piezoelectric layer 2 and the second piezoelectric layer The length of the piezoelectric layer 3 is 60% of the length of the elastic beam. The polarization direction of the first piezoelectric layer 2 and the second piezoelectric layer 3 is along the thickness direction of the cantilever beam, such as figure 1 In the direction of the arrow shown in P, the piezoelectric layer is made of piezoelectric ceramic sheets, and electrodes 4 are plated on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com