Experimental pasteurization machine

A pasteurizer and experimental technology, applied in food science, food preservation, application, etc., can solve the problems of poor data repeatability, waste of manpower, material resources and time, and achieve the effect of high degree of automation and beautiful products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

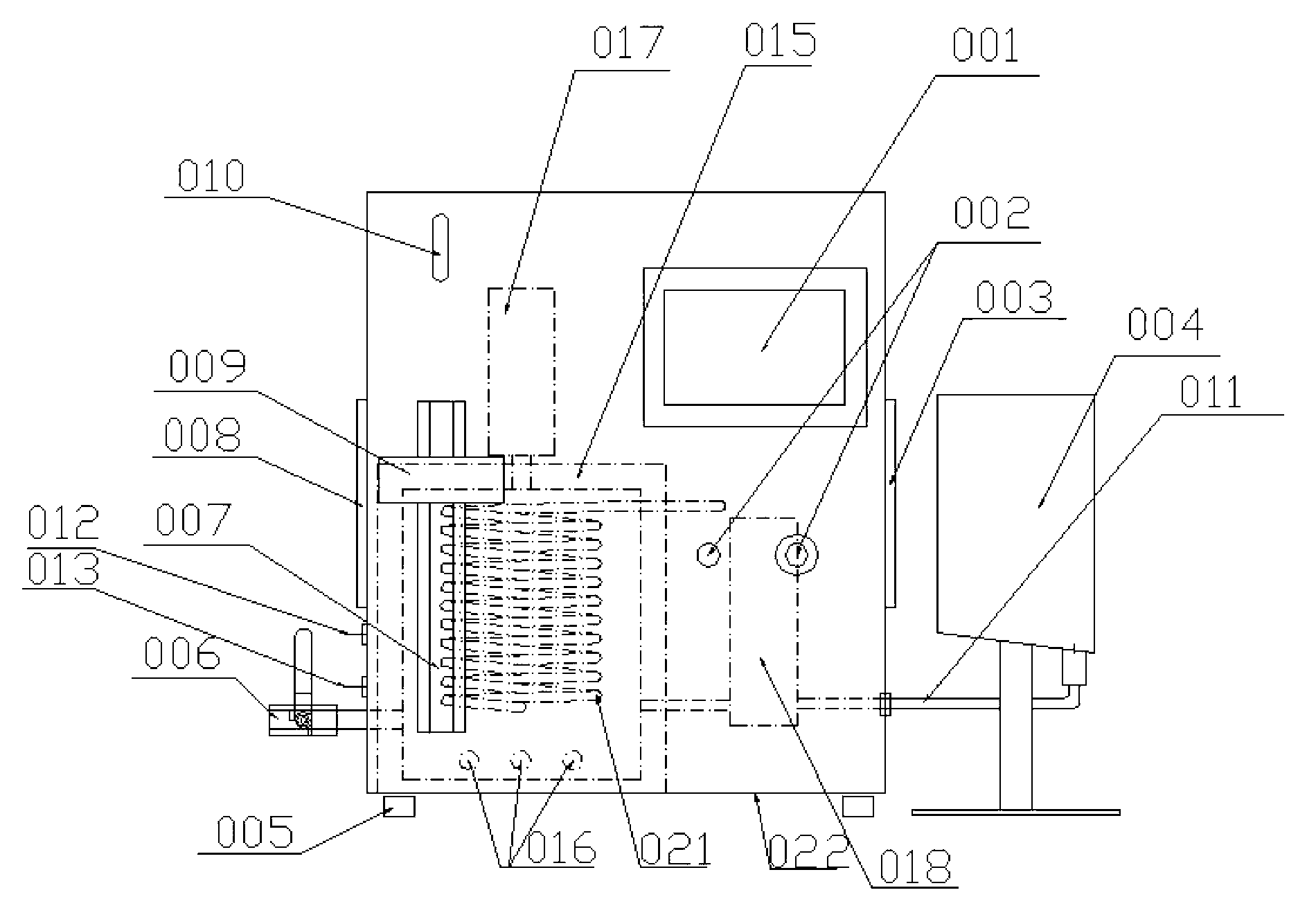

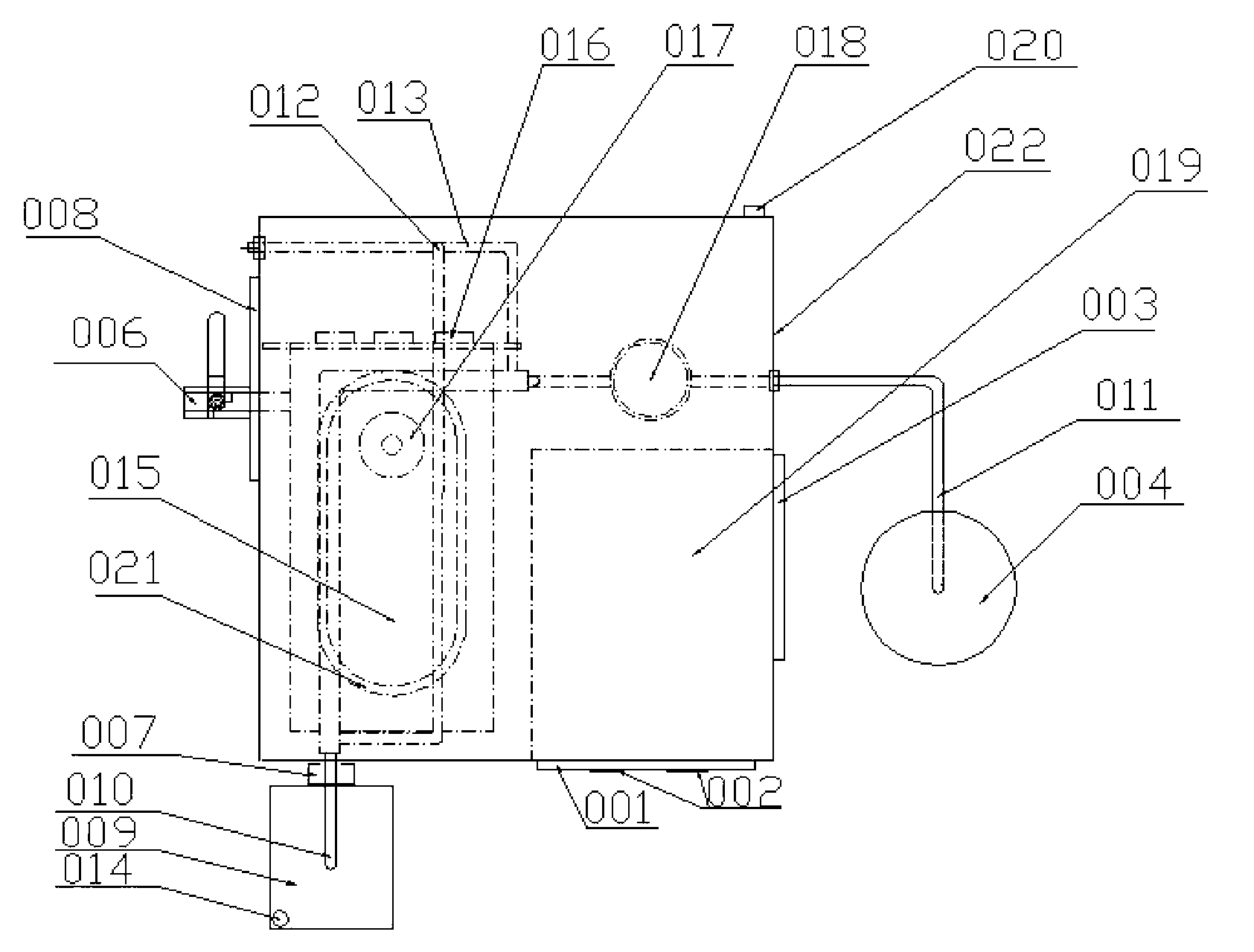

[0018] Such as figure 1 , 2 As shown, the present invention includes a touch screen, a material tank, a feed pipe, a power switch, a cooling water inlet pipe, a cooling water drain pipe, a heating tank, a sterilization coil, an oil drain valve, a heater, a slide rail, a refueling tank, a replacement Air window, material pump, material receiving tank, electric control system, material outlet and power supply,

[0019] The material pump, heating tank, sterilizing coil, heater, cooling water inlet pipe and cooling water drain pipe are arranged in the cabinet body, there are ventilation windows on the left and right sides of the cabinet body, and anti-vibration pads on the bottom of the cabinet body. An electric control system is provided, and the electric control system includes a touch screen for adjusting and setting various parameters, and the touch screen is fixed at the front of the cabinet,

[0020] The heating tank is fixed at the bottom of the cabinet, and heat-conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com