Recessed-point round-end S type tooth structure

A round head and concave point technology, applied in the field of its mechanical connection structure, can solve the problems of uneven chamfering of the beveled edge of the tooth foot, easy skew of the chain teeth, and insufficient verticality of the cloth tape, so as to achieve a smooth pulling feeling and enhance the bite. strength, the effect of highlighting substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below with reference to the accompanying drawings.

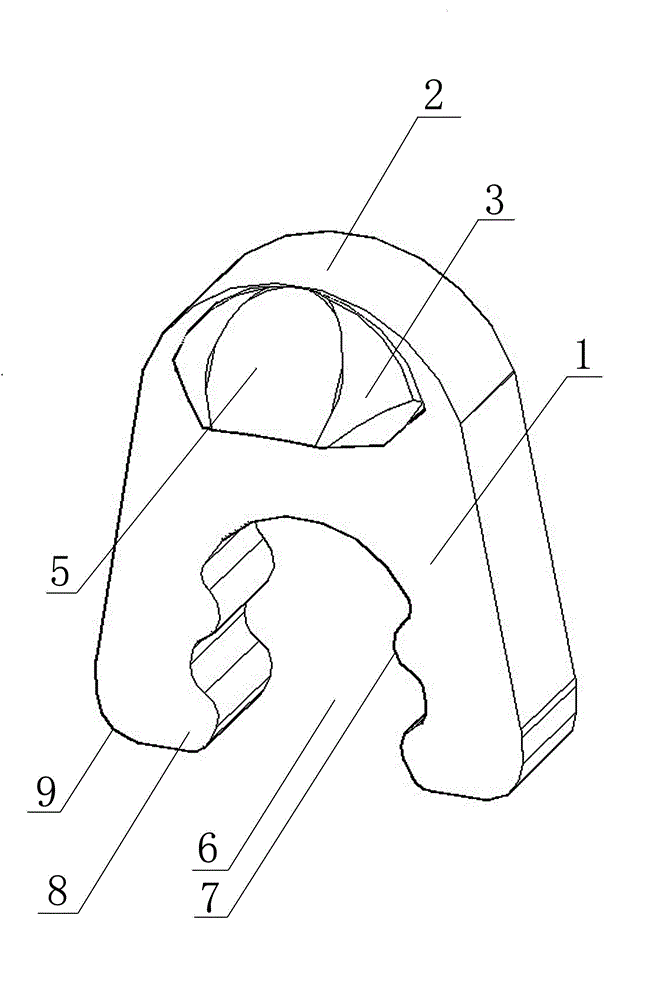

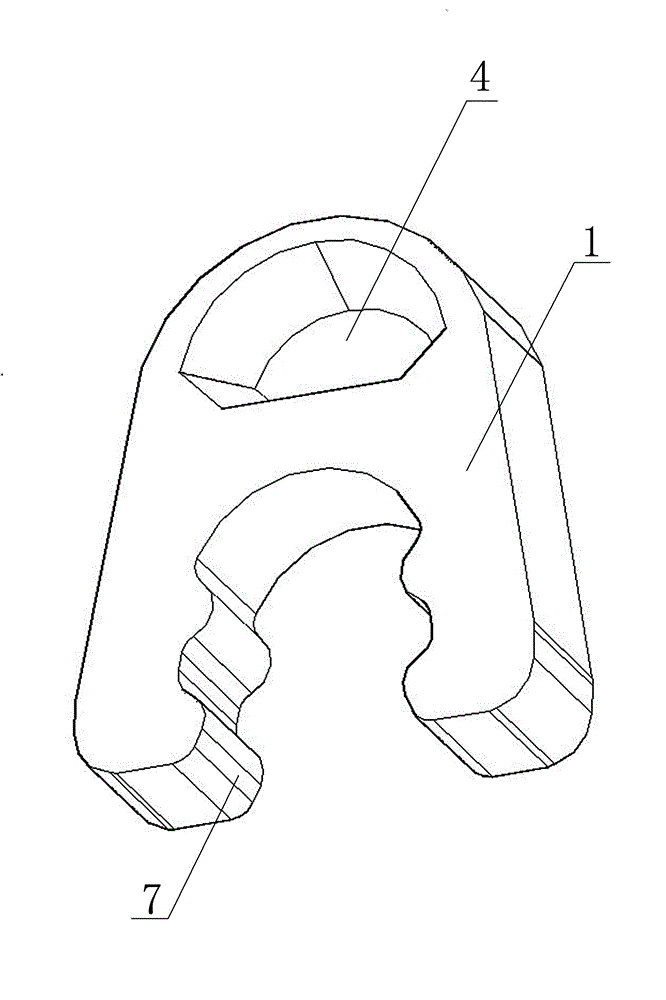

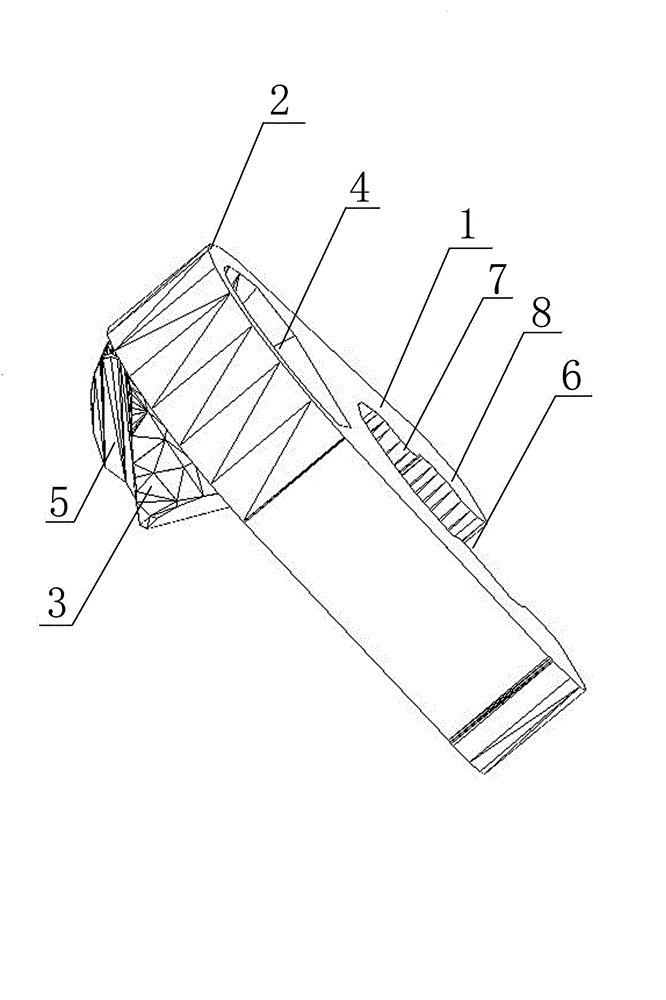

[0010] The present invention is a concave point round head S tooth structure, such as figure 1 As shown in , it mainly includes the tooth grain body 1, which is different from the prior art in that: the tooth head 2 at one end of the tooth grain body 1 is round, and the S teeth with the round head can effectively save the amount of copper wire, and the size is 10,000 yards larger. The round-headed S tooth can save about 39Kg of copper wire, which is equivalent to RMB 2145. The upper and lower surfaces of the tooth head 2 form a convex tooth point 3 and a concave tooth concave 4 respectively, and the surface of the tooth point 3 forms a depression 5 near the middle. The tooth foot 8 at the other end of the tooth grain body 1 is provided with a chain belt clip groove 6, and at least two serrated protrusions 7 are formed on the groove walls on both sides, one is located nea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap