Waste gas utilization system for paint spray booth

A paint spraying room and exhaust gas technology, applied in spraying devices, coatings, devices for coating liquid on the surface, etc., can solve problems such as prone to combustion and explosion, human body, and environmental hazards, and achieve pollution avoidance and system structure Concise and reasonable, realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

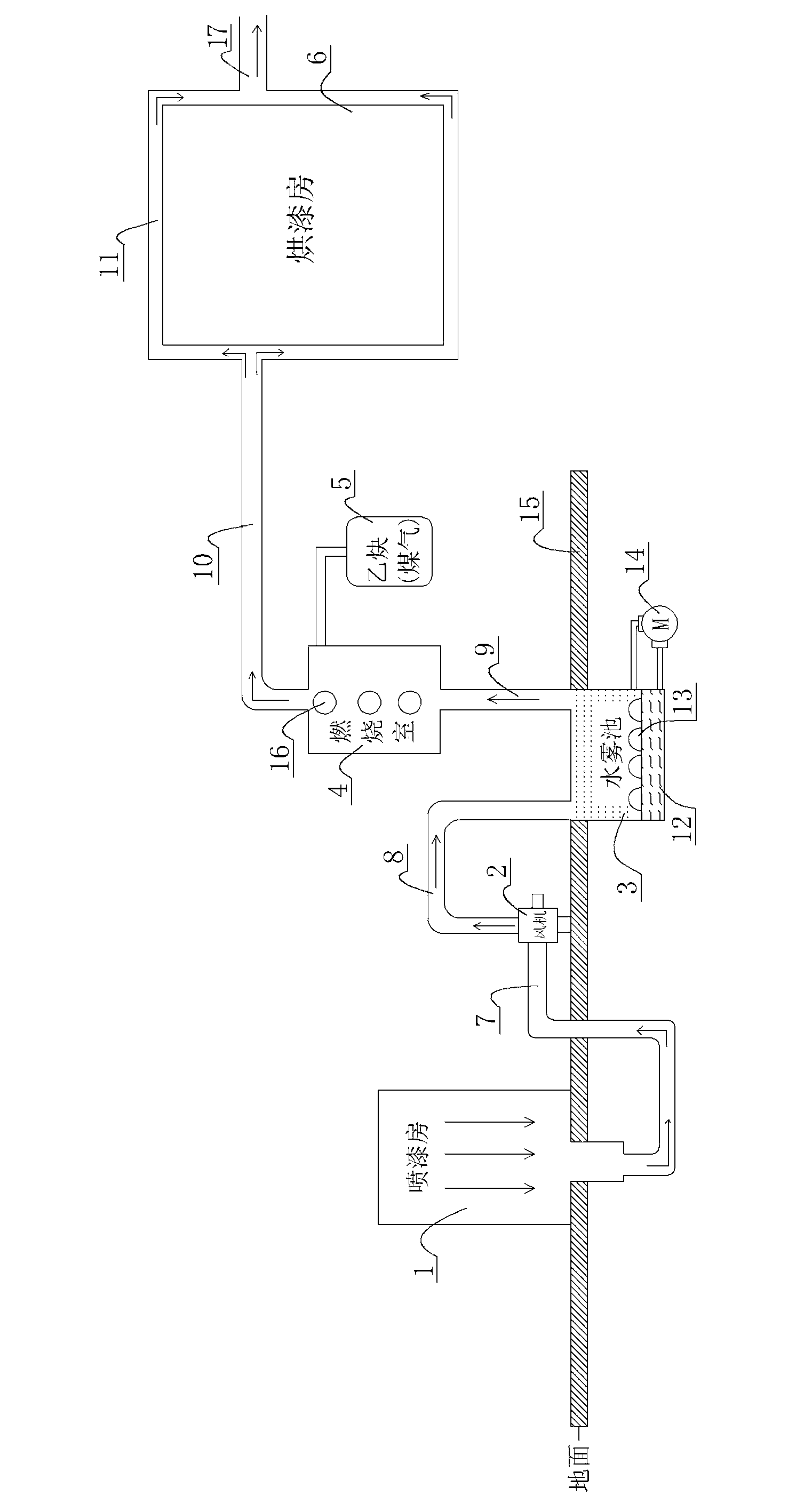

[0015] like figure 1 As shown, the structural principle diagram of the exhaust gas utilization system of the spray booth of the present invention is given, which includes a fan 2, a water mist pool 3, a combustion chamber 4, a gas tank 5, a paint drying room 6, a hydraulic pump 14, and an ignition device 16 . The fan 2 is provided with an air inlet pipe 7 and an air outlet pipe 8, and the fan 2 is respectively connected with the painting room 1 and the water mist pool 3 through the air inlet pipe 7 and the air outlet pipe 8, so that the fan 2 can spray paint in the painting room 1. The mixed gas produced in the process is sent into the water mist pool 3 . A plurality of atomizing nozzles 13 are arranged in the water mist pool 3, and the atomizing nozzles 13 are connected with the outlet of the water pressure pump 14, and the bottom of the water mist p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com