Isobaric threaded locking multi-contact rapid forming die

A fast, locking rod technology, used in forming tools, manufacturing tools, metal processing equipment, etc., to achieve the effect of simple, efficient and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

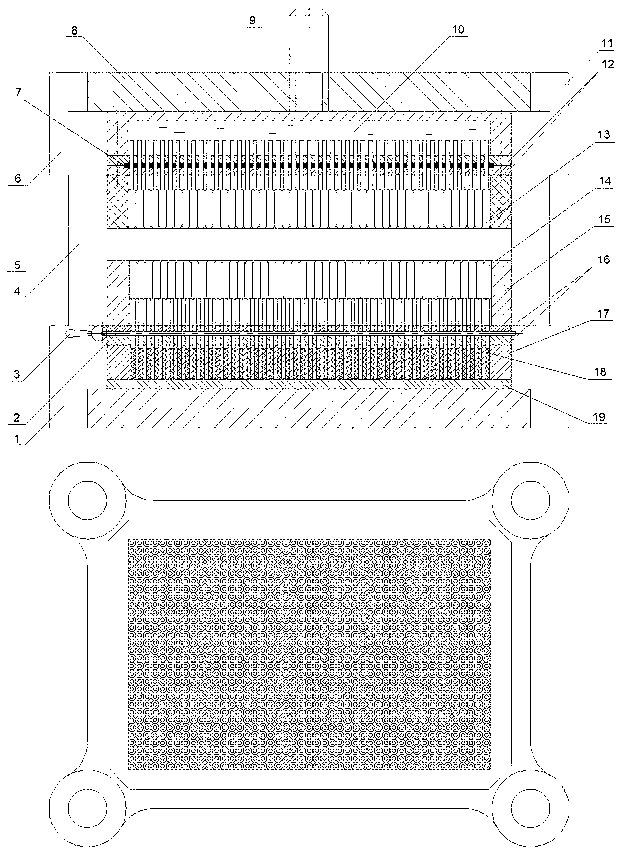

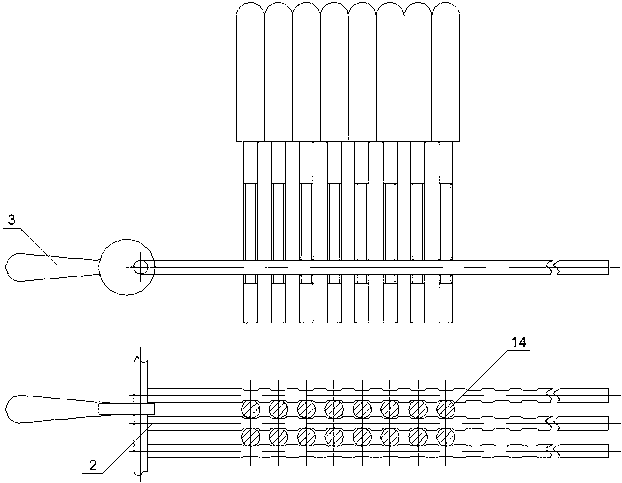

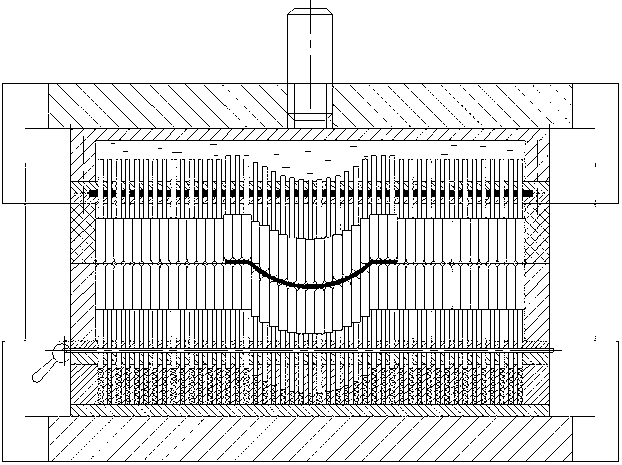

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The system structure and working principle are as follows: figure 2 , image 3 As shown, the prototype of the workpiece with the characteristics of deep drawing, undulation or beading is placed in the center of the contact pressure head 14 arranged in an array in the lower die 1, and a certain pressure is applied; the spring 18 at the lower end of the pressure head is compressed , the position of each contact pressure head 14 of the lower mold is changed accordingly until it is consistent with the outer surface of the prototype; press the locking handle 3, the eccentric mechanism makes the locking lever 2 be pulled out, and the locking lever 2 is The grooves of the lower die are engaged with the threaded ends of the contact heads 14 of the lower die to lock the contact heads 14 of the lower die, and the lower die obtains a complex internal shape consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com