a tractor

The technology of a tractor and a tractor is applied to the tractor. It can solve the problems of the traction head protruding from the track, the traction power is large, and the safety is poor, so as to achieve the effect of good starting control performance, low traction power, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

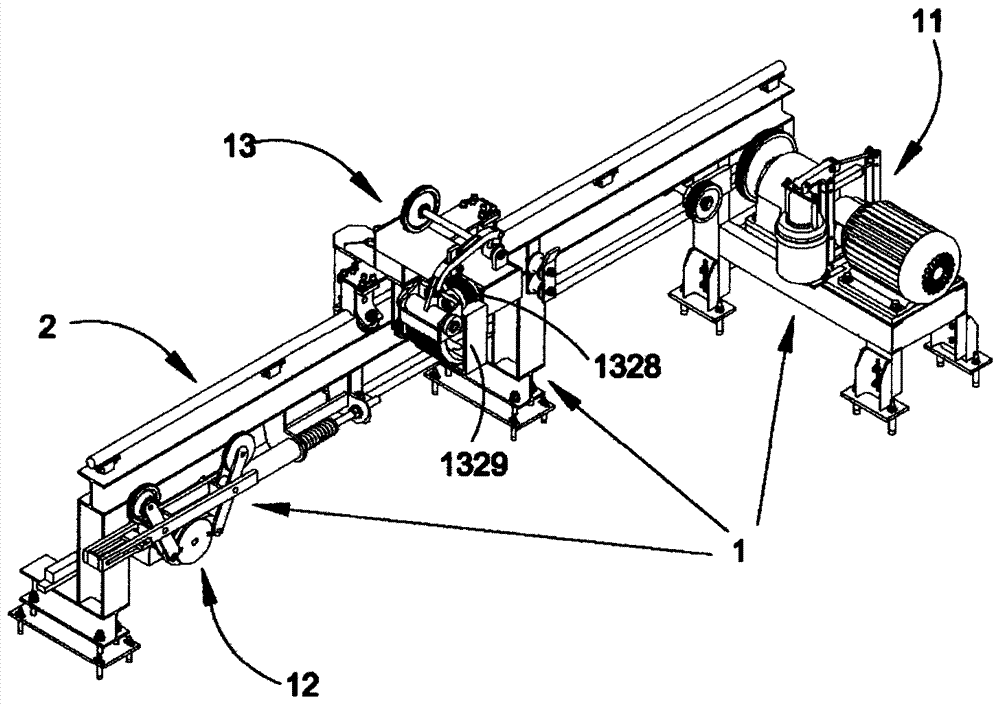

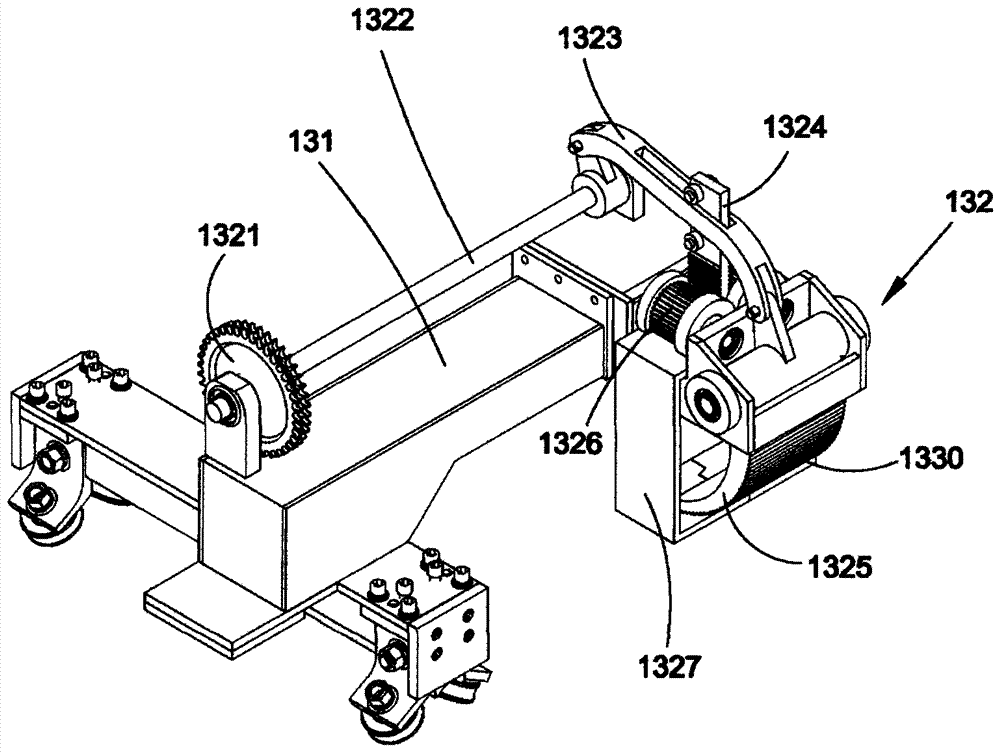

[0026] Such as Figure 1 to Figure 5 Shown is a preferred specific implementation example of the present invention, a tractor includes a traction unit 1 and a track 2, wherein the traction unit 1 includes a traction force power device 11, a material clamping power mechanism 12 and a traction head 13, the The traction head 13 is made up of a frame 131 and a clamping mechanism 132 installed on the frame 131 .

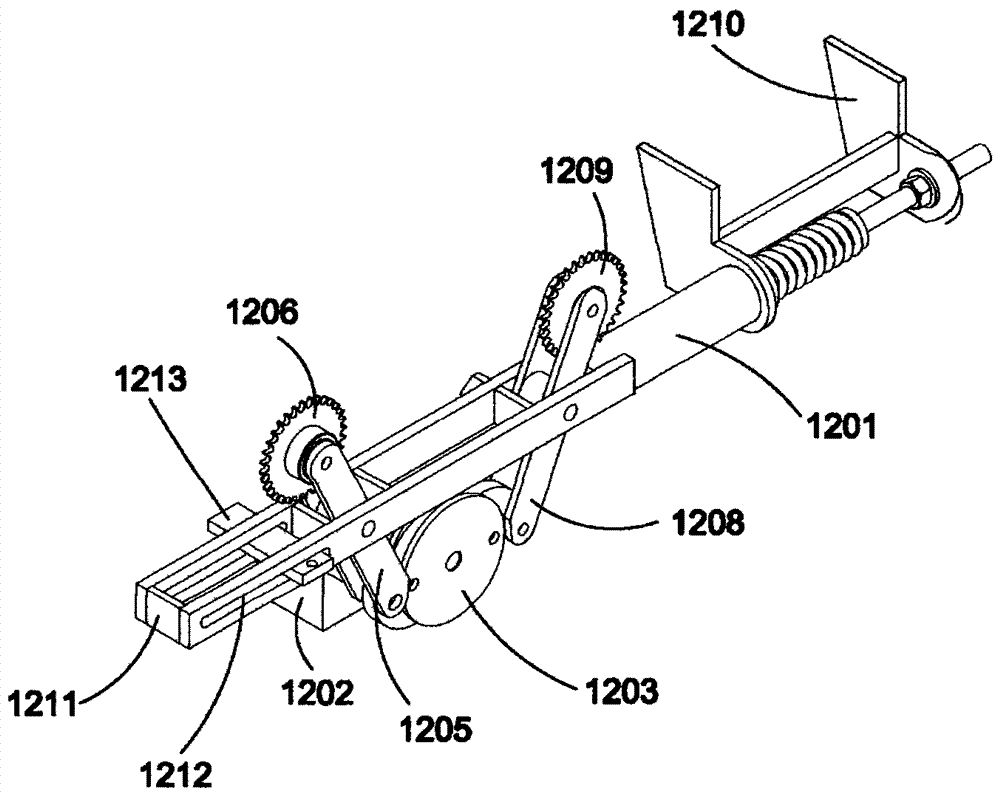

[0027] The traction power unit 11 is placed on one side of the track 2, and the traction power unit 11 is in transmission connection with the frame 131 on the traction head 13, and the frame 131 of the traction head 13 is slidably connected to the track 2. The material clamping power mechanism 12 is installed on the track 2 , and the material clamping power mechanism 12 is in transmission connection with the material clamping mechanism 132 of the traction head 13 .

[0028] Such as Figure 1 to Figure 2 As shown, the clamping mechanism 132 includes a first transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com